Частые проблемы с установкой шарового клапана ушного вала и способы их решения

Mar 19, 2024

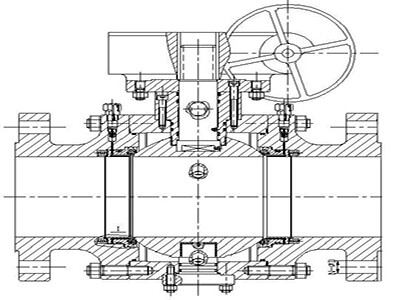

Trunnion mounted ball valves are widely utilized in industries such as petroleum and chemical engineering due to their versatility and reliability. However, like any mechanical component, they can encounter various issues during operation. Below, we outline common problems associated with trunnion mounted ball valves along with their respective solutions.

1. Leakage

Leakage is a prevalent issue with trunnion mounted ball valves, typically arising from poor sealing. This can result in gas or fluid leaks, leading to energy wastage and potential safety hazards. To address this, it's crucial to regularly inspect the valve's sealing rings, ensuring their integrity, and promptly replacing worn-out seals.

2. Blockage

Over time, trunnion mounted ball valves may accumulate debris or other contaminants, causing blockages within the valve. To maintain optimal flow, regular internal cleaning of the valve is necessary to remove any buildup.

3. Seizing

Extended periods of inactivity can cause trunnion mounted ball valves to become stiff or even seize up. To preserve the valve's flexibility, routine inspection of its moving parts and the application of appropriate lubricants are essential.

4. Operational Difficulty

Factors such as high frequency of use or harsh working environments can make operating trunnion mounted ball valves cumbersome, for instance, when valve stems become difficult to rotate. Addressing this issue involves selecting the appropriate length and material for valve handles based on the specific operational conditions to enhance ease of operation.

5. Structural Damage

In extreme circumstances, trunnion mounted ball valve bodies may sustain damage from external impacts. Implementing measures such as installing valve protection covers or setting up warning signs can help prevent such occurrences and safeguard the integrity and safety of the valve.

In summary, addressing common issues with trunnion mounted ball valves involves inspecting sealing components, cleaning the valve internals, lubricating moving parts, adjusting operational handles, and reinforcing protective measures. Only by ensuring the smooth operation of valves can we fully harness their functionality, thereby ensuring the seamless progress of industrial production.

Cледующий: Understand Principle and Key Features of Top-entry Ball Valves

Предыдущий: Технические характеристики высокопроизводительных бабочек

О нас

Продукция

Навигация

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China