Функция dbb шарового клапана трубопровода

Dec 02, 2024

On this page

Pipeline ball valves are essential components widely used in oil, gas, and other industrial pipeline systems. One of the most important features of these valves is their DBB (Double Block and Bleed) function, which plays a critical role in ensuring pipeline safety. The DBB function helps vent or drain the medium inside the ball valve body. This prevents pressure buildup and stops harmful substances from leaking out, improving the overall safety and stability of the system. In this article, we'll take a closer look at the basic principles, how the DBB function works, potential issues, and why regular maintenance is key to keeping it functioning properly.

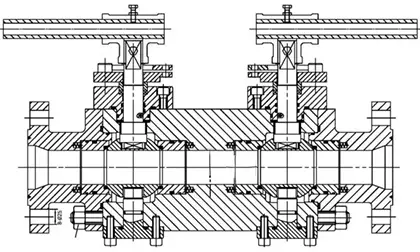

The DBB function works by using two sealing elements (one on the upstream side and one on the downstream side) in the ball valve design. When the valve is closed, these two seats handle the pressure from both the upstream and downstream media, forming double seals. This helps prevent leakage and prepares the valve for venting or draining operations.

The key to the DBB function is the design of two sealing elements. Each seat has its own sealing surface, one on the upstream side and one on the downstream side. When the ball valve is closed, both of these seats maintain a tight seal, preventing pressure from transferring directly to the pipeline. The valve body also includes an interface for releasing pressure, making venting or draining possible.

To make the DBB function work, the ball valve body has an interface designed to release pressure. Operators can use this interface to vent or drain the valve body when the valve is closed. This ensures that there is no continued flow of medium inside the valve, keeping the valve safe for long-term use.

The DBB function generally involves venting or draining. There are two main scenarios.

When venting or draining takes place, the pressure inside the ball valve body gradually decreases. If no more medium comes out after the venting or draining is complete, it means the DBB function is working as it should. The valve has successfully released the pressure, and it can remain closed, keeping the pipeline system safe.

If the pressure inside the ball valve body doesn't fully vent or drain, and medium continues to flow out, it indicates that the DBB function isn't working properly. In this case, operators will need to inspect or repair the valve to restore its normal function.

DBB function failure typically happens for two main reasons: defects during manufacturing or gradual wear and tear over time.

If the DBB function is missing, it's usually due to an issue during manufacturing. A design flaw or a quality control problem can prevent the ball valve from achieving the intended DBB function. This is a serious issue and typically requires the valve to be reworked or replaced.

The DBB function can also become damaged over time. As the ball valve is used, the seats can get worn down by corrosion or the buildup of impurities. This can cause the DBB function to fail. Common causes include:

Seat Leakage: Corrosion or wear can cause leaks on the sealing surfaces of the upstream and downstream seats, reducing the effectiveness of the DBB function.

Impurity Buildup: Impurities, especially in oil and gas pipelines, can accumulate inside the valve body, damaging the sealing surfaces of the seats.

External factors can affect the DBB function in long-term pipeline systems, especially in oil and gas pipelines, where the properties of the medium can have an impact.

Oil and gas pipelines are often exposed to harsh environments, which can lead to corrosion of the pipeline's inner walls. This corrosion can release rust, sand, and particles into the system. Oil and gas media also often contain impurities like sludge and oil residues. These impurities can enter the valve's sealing chamber during operation, leading to issues such as:

Scratching of Sealing Surfaces: Impurities can scratch the sealing surfaces of the ball and valve seat, causing leaks.

Impurity Buildup: Over time, impurities can accumulate in the ball valve. This can cause the valve to seize up, increase opening and closing torque, or even prevent the valve from opening or closing properly.

In high-pressure and high-temperature pipeline environments, the DBB function can also be affected. Excessive pressure and temperature can accelerate the wear of the sealing surfaces, causing the DBB function to fail. Therefore, it's important that the valve is made from materials that can handle these conditions and designed to ensure long-term stable operation.

The DBB function is vital for the long-term operation of pipeline ball valves. Regular venting and draining help extend the valve's service life and maintain its sealing performance. The benefits of regular venting and draining are as follows.

For ball valves with a single-piston effect (or self-venting) seat design, regular venting and draining help remove impurities from the valve body. This enhances the sealing performance of the seats. When the valve is closed, venting or draining ensures the seal is intact.

Regular draining helps prevent impurities from building up inside the ball valve, which can affect its internal structure. This reduces the risk of seat damage and prevents the valve from seizing up or becoming sluggish.

By regularly venting and draining the ball valve, you can reduce seat wear caused by impurities. This extends the valve's service life, reduces maintenance costs, and increases the overall safety of the pipeline system.

The DBB function of pipeline ball valves is essential for ensuring proper sealing and maintaining pipeline safety. Through the design of dual sealing elements, the DBB function allows the valve to release pressure from the valve body when closed, ensuring the stability of the pipeline system. However, factors like seat wear, impurity buildup, and corrosion can affect the DBB function. Regular venting and draining operations are key to maintaining the DBB function, improving sealing performance, and extending the ball valve's lifespan. These measures help ensure the safety and efficiency of the pipeline system.

Cледующий: соображения при выборе материалов пневматического шарового клапана

Предыдущий: сравнение электрических и пневматических клапанов

О нас

Продукция

Навигация

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China