Технические характеристики высокопроизводительных бабочек

Mar 18, 2024

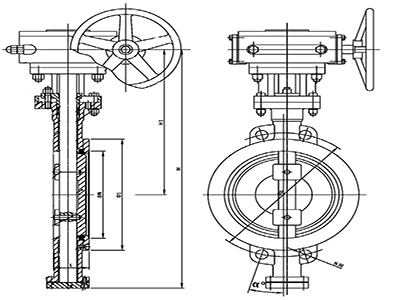

In industrial applications, the selection of valves is crucial for fluid control and pipeline operation. High-performance butterfly valves, as advanced automatic control valves, have gained widespread use in recent years. In comparison to conventional butterfly valves, high-performance butterfly valves offer significant advantages in terms of performance and reliability.

Issues with Conventional Butterfly Valves

Conventional butterfly valves suffer from various problems, including high opening torque, low sealing reliability, and short lifespan. During the opening and closing process, the valve disc and sealing ring are prone to tearing, resulting in high operating torque and inadequate sealing performance, thereby limiting their lifespan.

Features of High-Performance Butterfly Valves

High-performance butterfly valves address the shortcomings of conventional models while exhibiting the following notable features:

1. High-Performance Regulation and Shut-Off Type: These valves can function both as regulating and shut-off valves, offering versatile functionality.

2. Bi-Directional Sealing Type: Utilizing bi-directional sealing design, even in scenarios of medium backflow or "air hammer," reliable sealing is ensured, enhancing valve safety.

3. Integral Casting Technology: Employing integral casting technology for the valve body results in a compact structure, smaller volume, and lighter weight, enhancing operational convenience.

4. Eccentric Structure: The eccentric design facilitates rapid separation, effectively preventing seal ring wear, reducing operating torque, and prolonging valve lifespan.

5. Innovative Seal Ring Design: Novel seal ring designs, such as "lip-tooth" self-sealing structure for PTFE seals and U-shaped elastic seals for hard seals, offer long lifespan and high reliability. The choice between soft and hard seals depends on user requirements, operating conditions, and corrosion resistance needs.

6. Superior Flow Characteristics: These valves exhibit large flow capacity, low flow resistance, and a large flow path, virtually free of contraction, facilitating pipeline cleaning and self-cleaning. They effectively handle turbid, low-viscosity suspension particles, and fibrous media.

2. Bi-Directional Sealing Type: Utilizing bi-directional sealing design, even in scenarios of medium backflow or "air hammer," reliable sealing is ensured, enhancing valve safety.

3. Integral Casting Technology: Employing integral casting technology for the valve body results in a compact structure, smaller volume, and lighter weight, enhancing operational convenience.

4. Eccentric Structure: The eccentric design facilitates rapid separation, effectively preventing seal ring wear, reducing operating torque, and prolonging valve lifespan.

5. Innovative Seal Ring Design: Novel seal ring designs, such as "lip-tooth" self-sealing structure for PTFE seals and U-shaped elastic seals for hard seals, offer long lifespan and high reliability. The choice between soft and hard seals depends on user requirements, operating conditions, and corrosion resistance needs.

6. Superior Flow Characteristics: These valves exhibit large flow capacity, low flow resistance, and a large flow path, virtually free of contraction, facilitating pipeline cleaning and self-cleaning. They effectively handle turbid, low-viscosity suspension particles, and fibrous media.

Applications

High-performance butterfly valves find extensive applications across various industries including metallurgy, chemical engineering, power generation, textiles, food processing, pharmaceuticals, papermaking, as well as in municipal engineering and water treatment plants. They are employed for cutting off water, sewage, oil, or controlling gas medium pressure and flow rate. Their exceptional performance and reliability make them a preferred choice in industrial fluid control.

In summary, high-performance butterfly valves, with their outstanding features, serve as effective alternatives to conventional butterfly valves and have found widespread application in industrial settings. With ongoing technological advancements, they are expected to play an increasingly significant role in fluid control applications.

Cледующий: Частые проблемы с установкой шарового клапана ушного вала и способы их решения

Предыдущий: Основные советы по обслуживанию бабочки

О нас

Продукция

Навигация

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China