Поворотные обратные клапаны: конструкция, руководство по эксплуатации и техническому обслуживанию

Feb 26, 2024

Swing check valves, also referred to as one-way or non-return valves, play a pivotal role in preventing the reverse flow of media within pipelines. Operating on the principle of fluid dynamics and internal forces, these check valves automatically regulate the flow to prevent backflow, ensuring system integrity and safety. In this article, we will discuss the structural features, operating principles, as well as maintenance, installation, and usage guidelines for the swing check valve.

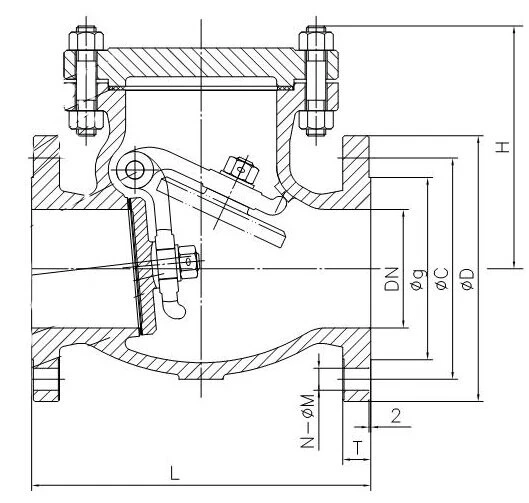

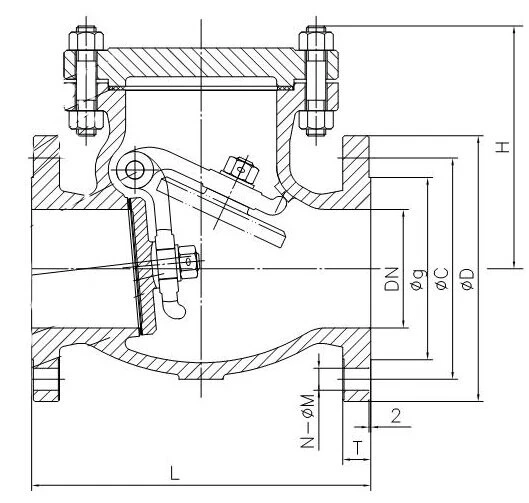

Principle and Structure

Operating Principle: Swing check valves utilize the movement of the piston plug to facilitate rapid opening and closing of the valve disc, ensuring a secure seal against backflow.

Structural Overview

Key Features of Swing Check Valves

Swing check valves are critical components in fluid systems, designed to prevent reverse flow and ensure the integrity of pipelines. Their key features make them highly effective and versatile in various applications. Here are the key features of swing check valves:

Maintenance and Care Guide

Maintaining and caring for swing check valves is crucial to ensure their optimal performance and longevity. Here is a comprehensive guide on the maintenance and care of swing check valves:

Installation and Usage

Proper installation and usage of swing check valves are essential for ensuring their optimal performance and longevity. Here is a comprehensive guide:

By adhering to proper maintenance, installation, and usage protocols, swing check valves offer an efficient and reliable solution for preventing backflow, safeguarding pipeline systems, and enhancing operational efficiency.

Principle and Structure

Operating Principle: Swing check valves utilize the movement of the piston plug to facilitate rapid opening and closing of the valve disc, ensuring a secure seal against backflow.

Structural Overview

- Type: Swing-type single-disc.

- Drive Mechanism: Welded connection.

- Connection Type: Welded connection.

- Valve operation controlled by pneumatic device for accelerated performance.

Key Features of Swing Check Valves

Swing check valves are critical components in fluid systems, designed to prevent reverse flow and ensure the integrity of pipelines. Their key features make them highly effective and versatile in various applications. Here are the key features of swing check valves:

- Compact Design: With a structural length ranging from 1/4 to 1/8 of traditional flanged check valves, swing check valves offer a space-saving solution.

- Lightweight Construction: Weighing only 1/4 to 1/20 of traditional counterparts, these valves are easier to handle and install.

- Rapid Closure: Swift valve closure minimizes water hammer pressure, reducing the risk of damage to the system.

- Versatile Installation: Suitable for both horizontal and vertical orientations, swing check valves offer flexibility in installation.

- Low Fluid Resistance: Streamlined flow passages ensure minimal fluid resistance, optimizing system efficiency.

- Responsive Operation: The valves exhibit quick response times and reliable sealing performance.

- Reduced Impact: Short valve stroke leads to minimal closing impact, prolonging equipment lifespan.

- Sleek Design: The compact and aesthetically pleasing design adds to the overall appeal of the system.

- Longevity and Reliability: Swing check valves boast a long service life and high reliability, minimizing maintenance requirements.

Maintenance and Care Guide

Maintaining and caring for swing check valves is crucial to ensure their optimal performance and longevity. Here is a comprehensive guide on the maintenance and care of swing check valves:

- Storage: Valves should be stored in dry, well-ventilated environments to prevent moisture accumulation and rust.

- Transportation: During transit, ensure closure devices are engaged and take precautions such as securing valve discs and sealing openings to prevent contamination.

- Inspection: Regular inspections, conducted bi-monthly, are essential to check for dirt, rust, seal integrity, and the condition of welded joints.

Installation and Usage

Proper installation and usage of swing check valves are essential for ensuring their optimal performance and longevity. Here is a comprehensive guide:

- Orientation: Install swing check valves vertically on horizontal pipelines, ensuring proper alignment for optimal performance.

- Initial Setup: For rotating swing check valves, begin with installation on horizontal pipelines, with the option to install closure valves on vertical lines where necessary.

- Pre-Installation Preparation: Clean valve passages and discs thoroughly to remove grease and contaminants.

- Media Consideration: Ensure media passing through the pipeline is free from hard particles to avoid damage to sealing surfaces.

- Quality Assurance: Each valve undergoes stringent testing before leaving the factory, ensuring reliability and performance.

By adhering to proper maintenance, installation, and usage protocols, swing check valves offer an efficient and reliable solution for preventing backflow, safeguarding pipeline systems, and enhancing operational efficiency.

Cледующий: Трехходовой шаровой клапан: обтекаемое решение управления жидкостью

Предыдущий: Обсуждение значения Y-образного фильтра в системе управления жидкостью

О нас

Продукция

Навигация

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China