Руководство по оптимизации и обслуживанию клиповой бабочки

Mar 09, 2024

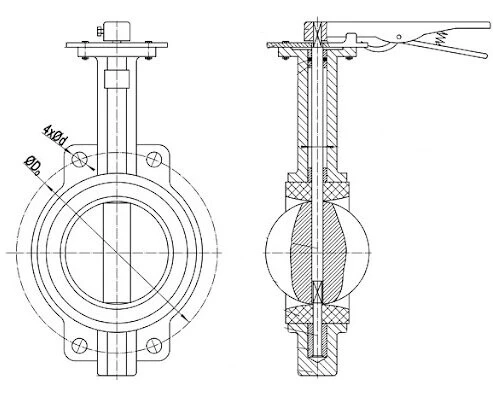

Wafer butterfly valves, renowned for their simplicity and superior performance, are indispensable in industrial settings for controlling pipeline flow. Despite their efficacy, ensuring sustained operation requires precise installation and diligent maintenance. This article explores strategies to enhance the utilization and upkeep of wafer butterfly valves, guaranteeing their reliability and durability under varying operational demands.

Pre-installation Preparation

Before installing wafer butterfly valves, a series of meticulous preparatory work is necessary to ensure the normal operation and safe usage of the valves.

1. Clean Pipeline and Valve Body: Thoroughly clean the pipeline and the flow passages of the valve body to prevent the entry of residual debris and foreign materials that may compromise the sealing performance of the valve.

2. Verify Operating Environment: Confirm whether the operating environment of the valve aligns with its performance specifications, including temperature and pressure requirements.

3. Inspect Valve Passages and Sealing Surfaces: Carefully inspect the valve passages and sealing surfaces for any debris or obstructions, and remove them to ensure unobstructed flow.

4. Handle Valve Installation with Care: Exercise caution when handling the valve bolts and nuts during installation to avoid damaging the valve structure.

5. Utilize Special Butterfly Valve Flange Gaskets: Ensure the use of specialized butterfly valve flange gaskets to achieve proper sealing and prevent leakage.

Maintenance Guide2. Verify Operating Environment: Confirm whether the operating environment of the valve aligns with its performance specifications, including temperature and pressure requirements.

3. Inspect Valve Passages and Sealing Surfaces: Carefully inspect the valve passages and sealing surfaces for any debris or obstructions, and remove them to ensure unobstructed flow.

4. Handle Valve Installation with Care: Exercise caution when handling the valve bolts and nuts during installation to avoid damaging the valve structure.

5. Utilize Special Butterfly Valve Flange Gaskets: Ensure the use of specialized butterfly valve flange gaskets to achieve proper sealing and prevent leakage.

To achieve optimal performance and longevity from wafer butterfly valves, it is imperative to adhere to a structured approach during regular maintenance inspections. Below is a comprehensive step-by-step guide:

- Visual Inspection: Commence by conducting a thorough visual examination of the valve and its surroundings. Scrutinize for any indications of leakage, corrosion, or physical damage. Focus attention on the valve body, sealing surfaces, connecting bolts, and operating stem.

- Operational Testing: Proceed to operate the valve to ascertain its smooth functionality. For manual valves, manipulate the handle to open and close it, ensuring ease of movement. Automatic valves should be tested using the control system to operate the actuator. Smooth and effortless opening and closing motions without undue resistance are indicative of proper operation.

- Leakage Check: While the valve is in operation, meticulously examine for any signs of leaks, paying close attention to sealing areas and the valve stem. The detection of leaks could signify seal failure, necessitating immediate repair or replacement.

- Actuator Inspection: For automatic valves, conduct a detailed inspection of the actuator and its connections. Verify the stability of the power supply and the accuracy of control signals. Any irregularities identified could adversely affect valve operation and should be promptly addressed.

- Lubrication of Stem: Apply an appropriate amount of lubricant to the valve stem to ensure smooth operation. While this step is particularly crucial for manual valves, it may also be necessary for automatic valves depending on their design.

- Operating Condition Verification: Conclude the inspection by verifying the operating conditions, including pressure, temperature, and fluid type, to ensure they align with the specified limits for the valve. Operating conditions outside the prescribed range may lead to valve failure and should be rectified promptly.

In conclusion, meticulous pre-installation steps and structured maintenance routines are crucial for optimizing wafer butterfly valve performance in industrial settings. By ensuring cleanliness, proper handling during installation, and regular inspections for leaks and operational issues, users can minimize downtime and maximize efficiency. Investing in optimization and maintenance efforts ensures the reliable operation of these critical components in industrial processes.

Cледующий: Основные советы по обслуживанию бабочки

Предыдущий: Распространенные неисправности и предосторожности при эксплуатации низкотемпературного

О нас

Продукция

Навигация

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China