обратный клапан подъема против запорного клапана: конструкция и применение

Sep 24, 2024

On this page

Lift check valves and globe valves are two commonly used types of valves in industrial production. While they share similarities in structure, particularly in the design of the valve body and disc, they differ significantly in terms of working principles and application scenarios. This article provides an in-depth analysis of the structural features, working principles, advantages and disadvantages, and application scenarios of these two types of valves to aid in understanding and selecting the most suitable valve type.

Lift check valves have many structural and functional similarities with globe valves, yet their operating principles and application contexts are markedly different. Below is a detailed introduction to the structural characteristics, working principles, pros and cons, and applicable working conditions for lift check valves.

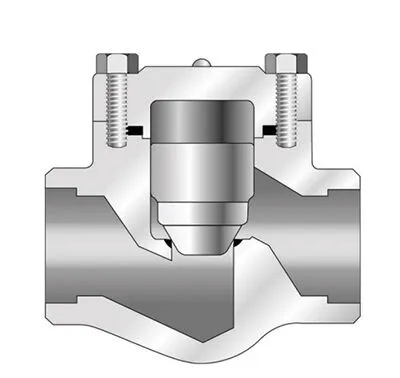

The body structure of a lift check valve resembles that of a globe valve. It features a set of guiding shafts and bushings positioned between the upper part of the disc and the lower part of the bonnet. The guiding shaft allows the disc to move freely up and down within the bushing. This design ensures that the disc accurately returns to the valve seat upon closure, ensuring sealing performance. The upper part of the guide bushing has a pressure relief hole, which allows the medium inside the bushing to be discharged when the disc rises, reducing resistance during valve opening.

The disc of the lift check valve operates automatically and typically consists of a conical disc pressed against a metal valve seat. When the fluid flows in the forward direction, the pressure of the fluid causes the disc to lift off the seat, opening the valve. Conversely, when the fluid flows backward, the disc returns to the seat due to its own weight, the preloaded spring force (if a spring is present), and the reverse flow pressure, thereby closing the valve. This valve usually employs a metal-to-metal sealing structure, allowing for minimal leakage. It is primarily used in scenarios where tight sealing is not critical, such as preventing condensate backflow in water systems.

Advantages

Simple Structure: Featuring only one moving component—the disc—this valve is simple, robust, and requires minimal maintenance.

High Wear Resistance: The metal seat design results in lower wear and longer service life.

Quick Closing: With a short stroke, approximately one-third of the disc diameter, the valve closes quickly, effectively reducing water hammer pressure.

Disadvantages

High Flow Resistance: Lift check valves exhibit high flow resistance, making them unsuitable for large diameters and high-flow scenarios.

Installation Constraints: Must be installed horizontally, limiting its use in certain pipeline configurations.

Lift check valves are mainly used in water systems to prevent condensate backflow, such as at the outlets of steam traps and condensate circulation pumps. They are also found in situations requiring automatic prevention of reverse flow, such as small-diameter water supply lines and industrial water supply systems.

Globe valves are widely used in pipeline systems due to their excellent sealing performance and effective flow regulation capabilities. They achieve precise control of medium flow through the movement of the valve disc, driven by the rise and fall of the valve stem.

A globe valve operates by moving the valve disc through the rise and fall of the stem, altering the distance between the disc and the seat to control valve opening and closing. The top of the valve body is equipped with a handwheel and stem, while the middle contains a threaded section and packing seal. Leakage may occur at the connection between the stem and bonnet, which is typically addressed with packing seals. In small globe valves, the stem threads are located inside the valve body and in direct contact with the medium, making them prone to corrosion.

The opening and closing of a globe valve are controlled by the rise and fall of the valve stem. When the handwheel is turned clockwise, the stem drives the disc downward to press against the seat, closing the valve. When the handwheel is turned counterclockwise, the stem rises, increasing the distance between the disc and the seat, opening the valve. By adjusting the distance between the disc and the seat, precise flow control can be achieved.

Advantages

Excellent Flow Regulation: Globe valves provide precise control of fluid flow, making them suitable for systems requiring frequent adjustments.

Compact Structure: They have a compact shape, easy operation, and a handwheel that requires little force to operate.

Minimal Water Hammer: With slower opening and closing speeds, water hammer is rarely an issue.

Disadvantages

Susceptible to Corrosion: The stem threads of small globe valves, in prolonged contact with the medium, are prone to corrosion.

Unsuitable for High-Viscosity Media: They are not ideal for high-viscosity or crystallizing media, such as slurry or grease.

Globe valves are widely used in various fluid (e.g., water, steam, compressed air) pipelines for on-off control. They are also found in systems requiring frequent flow regulation, such as in chemical, metallurgy, and power industries. These valves are suitable for low flow velocity and small-diameter scenarios, but not for high-viscosity or crystallizing media.

While lift check valves and globe valves share some structural similarities, they differ significantly in application, operating principles, and suitable scenarios. Here is a comprehensive comparison of these two valves to better understand their respective advantages and limitations.

Structural Comparison: Both have similar valve body and disc designs. However, the globe valve controls flow through the movement of the stem and disc, while the lift check valve automatically opens and closes based on the direction of fluid flow.

Working Principle: The globe valve is manually or automatically operated by controlling the stem's rise and fall. The lift check valve relies on the pressure differential of the fluid's forward and reverse flow to operate, making it ideal for preventing backflow.

Flow Control: Globe valves are suitable for applications requiring frequent flow adjustments, such as industrial control systems. Lift check valves are suitable for systems requiring automatic prevention of reverse flow.

Installation Requirements: Lift check valves must be installed horizontally, while globe valves can be installed according to specific working conditions.

Applicable Media: Lift check valves are typically used for water, condensate, and other non-crystallizing media. Globe valves are used for regulating and on-off control of various liquids and gases.

Both lift check valves and globe valves offer unique advantages in industrial pipeline systems. Choosing the right valve type requires a comprehensive consideration of factors such as fluid properties, pipeline layout, operating conditions, and installation space. Lift check valves are simple, durable, and require little maintenance, making them suitable for scenarios requiring backflow prevention. Globe valves, with their excellent regulation and control capabilities, are widely used in various industrial production fields. A rational choice of valve type can significantly enhance the reliability and safety of system operations.

Cледующий: функциональность пружинного параллельного двойного задвижки

Предыдущий: ключевые характеристики и преимущества производительности двухпластинного обратного клапана

О нас

Продукция

Навигация

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China