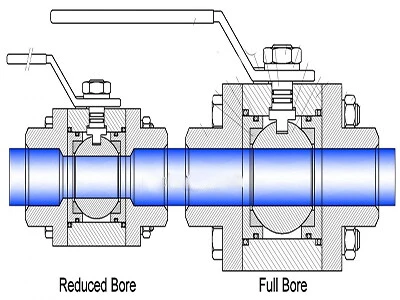

Сравнение шарового клапана полного прохода и шарового клапана усадочного диаметра

Apr 08, 2024

In the pipeline system, ball valves, as a crucial type of valve, play a pivotal role in controlling fluid flow. Among them, full bore ball valves and reduced bore ball valves are two common types, distinguished by their structural and functional differences, serving various process scenarios.

Characteristics of Full Bore Ball Valves

The design of full bore ball valves ensures that the flow passage size matches the valve port, guaranteeing unimpeded fluid flow. This design makes full bore ball valves particularly suitable for situations requiring high flow rates or complete blocking of fluid flow. For example, in a DN50 full bore ball valve, the flow passage diameter needs to be around 50 mm to ensure the smooth flow of a large volume of fluid. Full bore ball valves are also commonly used in scenarios requiring the use of "pigs" to clean the inside of pipelines, ensuring pipeline cleanliness and unobstructed flow.

Features of Reduced Bore Ball Valves

In contrast, the inlet of a reduced bore ball valve is slightly wider than the flow passage diameter, resulting in an actual diameter slightly smaller than the specified size by one specification. For instance, in a DN50 reduced bore ball valve, the flow passage diameter is approximately around 38 mm, equivalent to DN40 specification. The design objective of reduced bore ball valves is to precisely control flow by throttling or shutting off flow to regulate fluid flow. This makes reduced bore ball valves particularly suitable for process scenarios requiring precise flow control, such as systems needing strict control of flow velocity or flow rate.

Their Major Differences

Full bore ball valves and reduced bore ball valves exhibit distinct differences in internal structure and functionality. The flow passage size of full bore ball valves matches the valve port, ensuring unrestricted fluid flow, whereas the actual diameter of reduced bore ball valves is slightly smaller than the specified size by one specification, suitable for scenarios requiring precise flow control.

As essential types of valves in pipeline systems, ball valves come in full bore and reduced bore designs. Choosing the appropriate type of ball valve is crucial to ensuring the proper functioning of the system and production efficiency. Full bore ball valves are suitable for situations requiring high flow rates or complete blocking of fluid flow, while reduced bore ball valves are suitable for process scenarios requiring precise flow control.

Cледующий: Тип и применение смазочного кранового клапана

Предыдущий: Узнать основные принципы и основные преимущества кранового клапана

О нас

Продукция

Навигация

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China