What is difference between DBB and DIB ball valves?

Feb 28, 2023

DBB-Double Block and Bleed

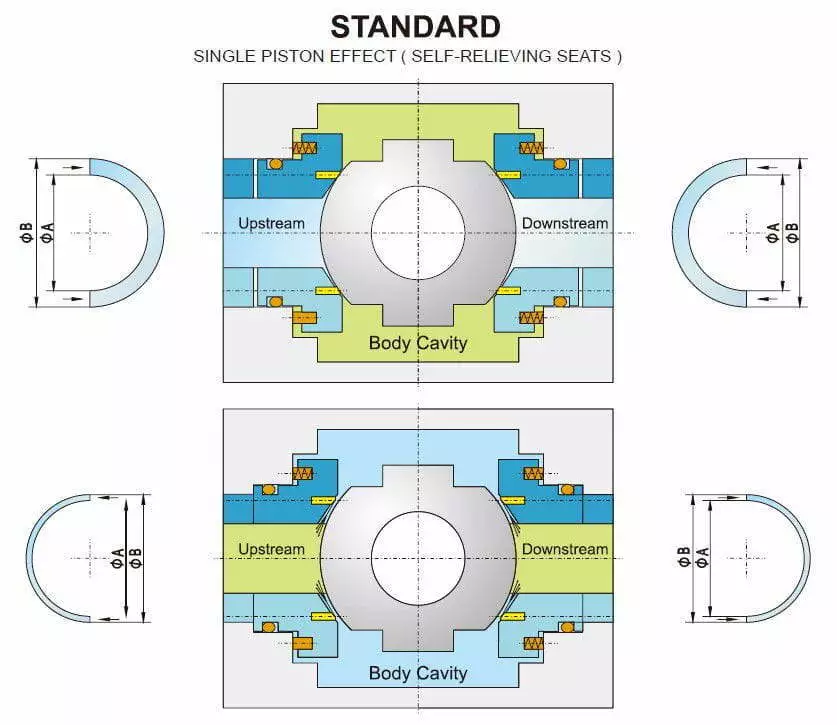

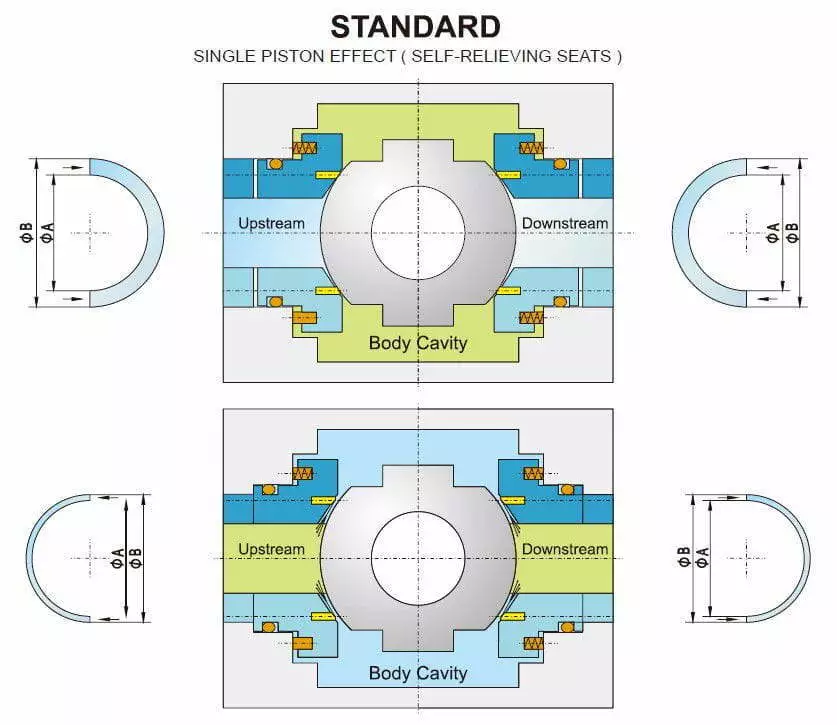

Seat Design: Single Piston Seats on both sides

The seats can be forced to the ball by pressure from upstream and downstream, but when the body cavity pressure is higher than the piping pressure, the seats will be pushed away from the ball and release the body cavity pressure.

But it also means that, in case one side seat fails to work, the pressure will push the seat on another side away from the ball and cause leakage. The seats are in single-direction sealing.

(The moving of the seats is mainly realized by the pressure difference caused by the flow pressure on the seat surface, see the relationship of ФA, ФB, ФC )

DIB-Double Isolation and Bleed

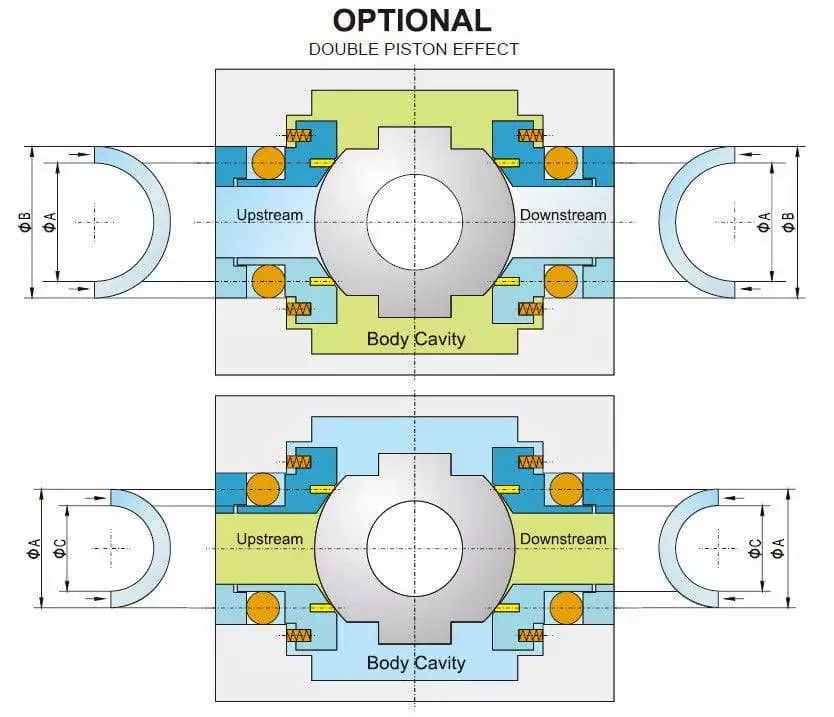

DIB-1

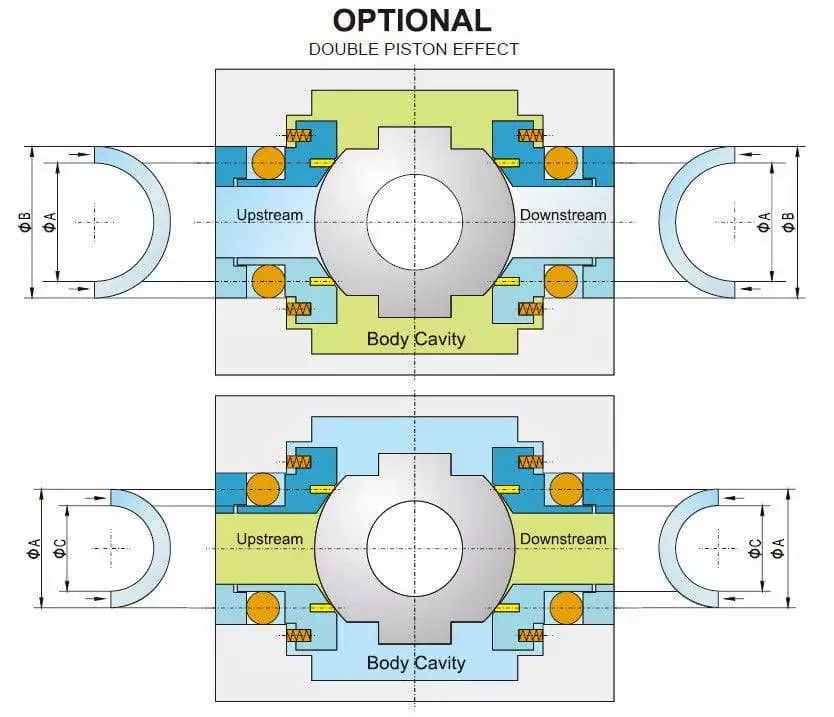

Seat Design: Double Piston Seat on both sides

Double piston effect seats are pressure energized in both directions. So the seat rings are always pushed against the ball by the pressure from upstream/downstream or from the cavity. If the upstream seat fails, the downstream seat can still ensure a tight seal. Since double piston effect valves do not have a self-relieving function, the automatic cavity-pressure relief valve shall be provided, unless otherwise agreed.

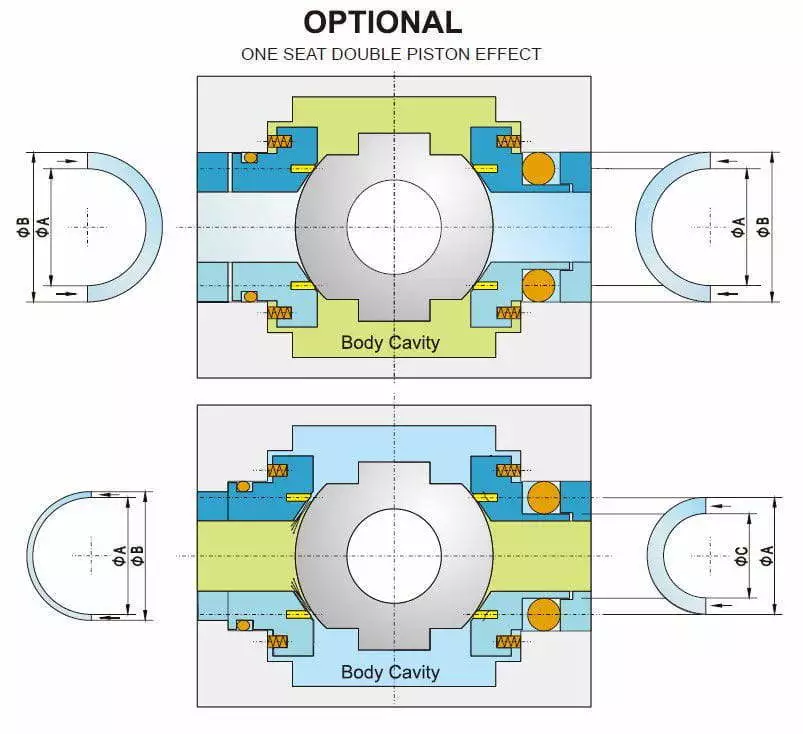

DIB-2

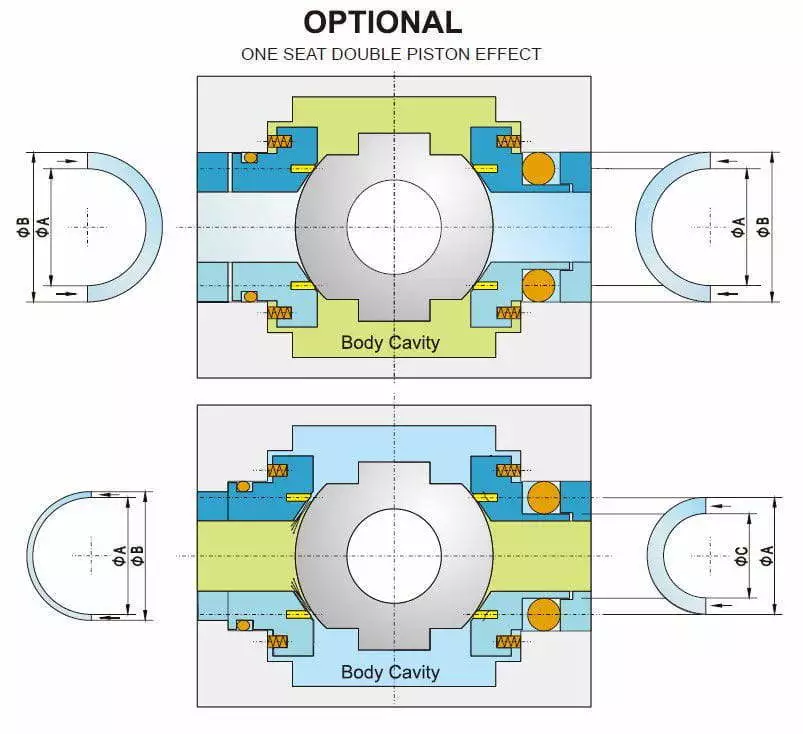

Seat Design: Double Piston Seat at one side and a single-piston seat on another side

If the force created by the body cavity pressure is greater than the preloaded spring force plus the force created by the pressure from the pipeline, the cavity pressure releases via the self-relieving seat, or when the single piston seat fails to work, the double piston effect seat still functions a tight seal.

Seat Design: Single Piston Seats on both sides

The seats can be forced to the ball by pressure from upstream and downstream, but when the body cavity pressure is higher than the piping pressure, the seats will be pushed away from the ball and release the body cavity pressure.

But it also means that, in case one side seat fails to work, the pressure will push the seat on another side away from the ball and cause leakage. The seats are in single-direction sealing.

(The moving of the seats is mainly realized by the pressure difference caused by the flow pressure on the seat surface, see the relationship of ФA, ФB, ФC )

DIB-Double Isolation and Bleed

DIB-1

Seat Design: Double Piston Seat on both sides

Double piston effect seats are pressure energized in both directions. So the seat rings are always pushed against the ball by the pressure from upstream/downstream or from the cavity. If the upstream seat fails, the downstream seat can still ensure a tight seal. Since double piston effect valves do not have a self-relieving function, the automatic cavity-pressure relief valve shall be provided, unless otherwise agreed.

DIB-2

Seat Design: Double Piston Seat at one side and a single-piston seat on another side

If the force created by the body cavity pressure is greater than the preloaded spring force plus the force created by the pressure from the pipeline, the cavity pressure releases via the self-relieving seat, or when the single piston seat fails to work, the double piston effect seat still functions a tight seal.

Next: Soft Seal Material Options for Ball Valves

Previous: Trim Numbers of Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China