Valves for FPSO Projects

Feb 21, 2025

Bosseal Factory is a professional valve manufacturer for offshore projects, including platforms, vessels, FLNG, and FPSO.

What's FPSO?

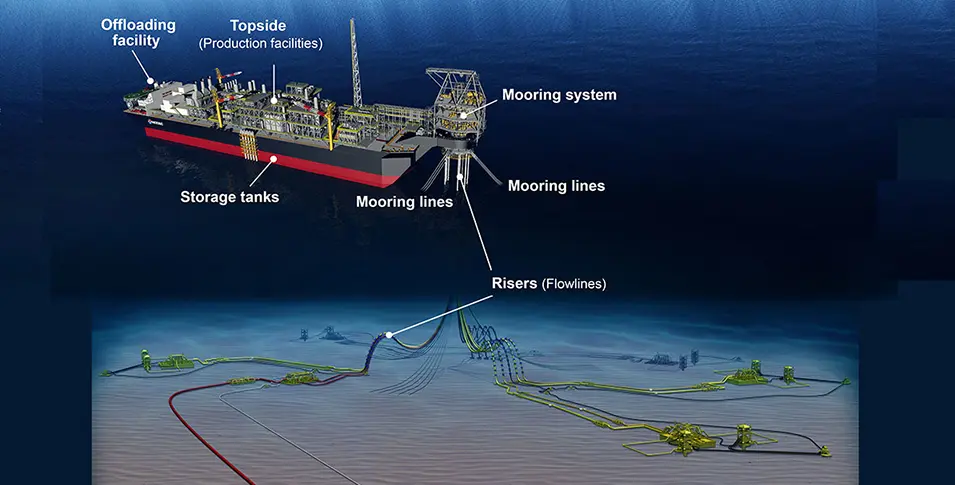

FPSO (Floating Production Storage and Offloading) is a floating production system that processes and stores hydrocarbons extracted from subsea reservoirs. It receives fluids, such as crude oil, natural gas, and water, through risers, then separates them onboard within the topside production facilities. The processed crude oil is stored in onboard storage tanks and later offloaded onto shuttle tankers for transportation to market or onshore refineries.

Different Types of FPSO

FPSOs are classified into the following types:

Floating storage and offloading (FSO)

Floating production storage and offloading (FPSO)

Floating drilling production storage and offloading (FDPSO)

Floating storage regasification unit (FSRU)

What's Advantage of FPSO?

Floating Production, Storage, and Offloading (FPSO) vessels are particularly effective in remote or deep-water locations where seabed pipelines are not cost-effective.

Valve Design for FPSO Applications

1. Marine Painting

The coating system for FPSO valves should be selected based on service conditions, including temperature and isolation requirements (isolated or unisolated). Generally, ISO 12944 C5 coating is the minimum standard to ensure durability in offshore environments. Common coating brands include International, AkzoNobel and Jotun. Strict quality control is essential before and during painting, focusing on surface cleanliness, roughness, and adhesion testing to ensure long-term performance.

2. Anti-corrosive Materials

The offshore environment is highly corrosive due to humidity and salt exposure, requiring special material treatments:

Bolts should have Zn-Ni coating or Xylan coating for corrosion protection.

Critical valve components should be at least SS 316 for corrosion resistance.

Topside valves may require duplex or super duplex stainless steel for enhanced durability in harsh marine conditions.

3. Longer Design Life

FPSO valves must be designed for long service life to minimize maintenance risks, which can impact safety and operational costs. Several factors should be considered:

Sealing materials must offer high stability.

O-rings should comply with NORSOK standards, such as O-Lion 101 and O-Lion 985, or use Lip Seal PFE + Elgiloy for superior sealing performance.

Welding overlay on sealing areas enhances wear and corrosion resistance.

4. Society Classification

A ship classification society or ship classification organization is a non-governmental entity that establishes and maintains technical standards for the construction and operation of ships and offshore structures. Classification societies certify that a vessel's construction complies with relevant standards and conduct regular in-service surveys to ensure ongoing compliance.

For FPSOs operating in different regions, they must adhere to the applicable classification society standards. The materials used in the FPSO, including valves, must undergo classification procedures like factory evaluation, design evaluation, product testing, and supplier (raw material) qualification.

Commonly used classification societies include LR, BV, DNV-GL, and ABS.

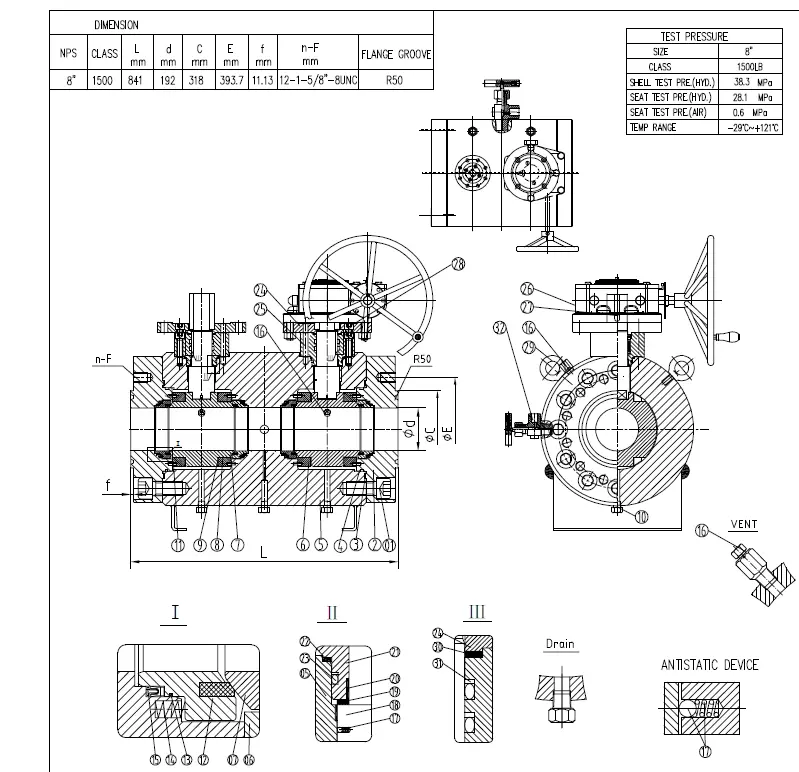

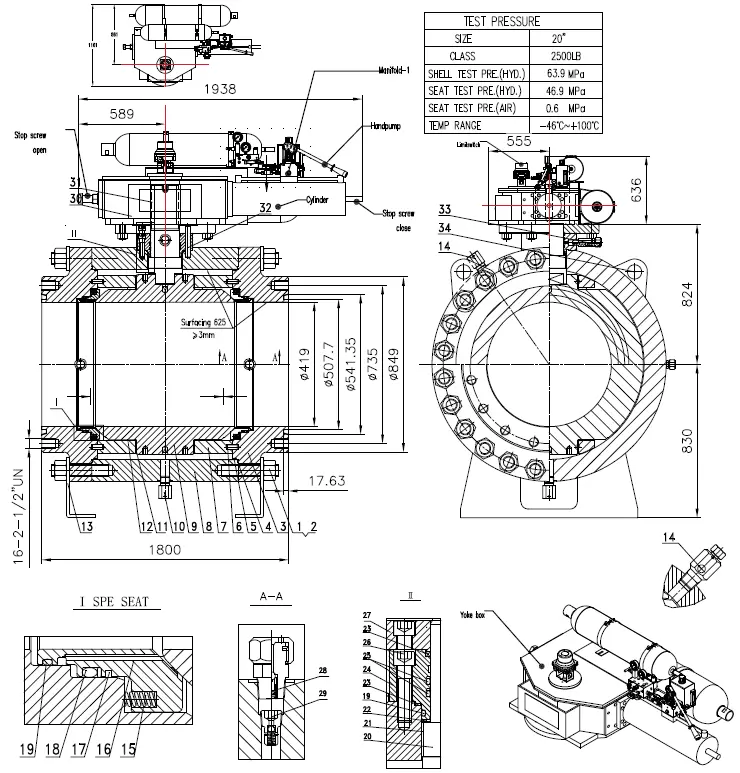

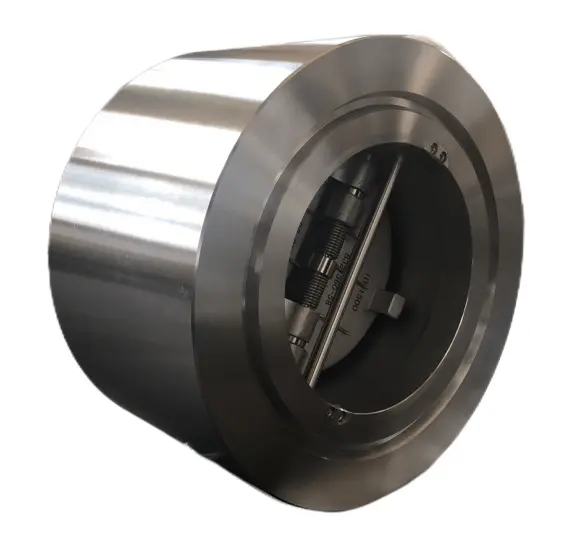

5. Compact Design

To reduce equipment weight, valves are typically selected with a smaller yet stronger design, often featuring a quick shut-off function. This is why ball valves and butterfly valves constitute a significant portion of the valve supply for FPSOs. The selection also includes SDV, ESDV, MOV, and ON/OFF valves.

For example, high-pressure twin ball valves are commonly used, offering double isolation while maintaining a shorter face-to-face dimension.

6. Special Material

Aluminum-bronze, titanium, duplex, and Inconel valves are also used for specific services on FPSOs.

Additionally, there are numerous specifications for FPSO valves. Major industry players have established comprehensive standards for materials, which manufacturers must understand and adhere to during production.

Main Players of the FPSO

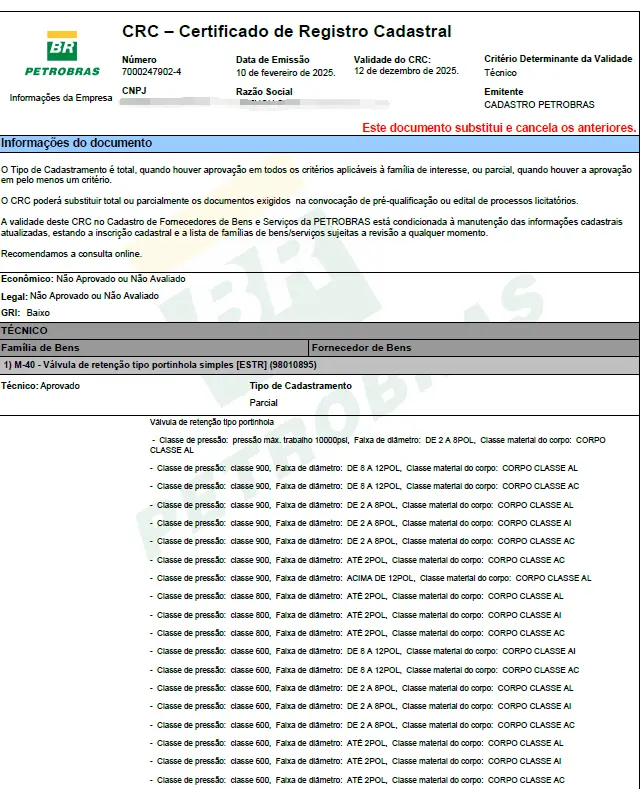

End Users: Petrobras, Shell, Petronas, Chevron, Total

FPSO Contractors: Modec, SBM, Saipem, Seatrium, Sembcorp

We are a Petrobras-qualified manufacturer with a valid CRC.

Our Valves for FPSO Projects

Bosseal Valves is a professional valve manufacturer specializing in offshore projects with high-quality requirements for offshore platforms and FPSOs. We offer a wide range of valves made from special materials such as duplex, alloy, and titanium. For any technical or commercial support, please consider our teams at [email protected].

Next: An Introduction to Spring Return Lever Ball Valves

Previous: Cryogenic Valve Structural Features & Technical Requirements