Understand the Principle and Features of Globe Valve

Feb 27, 2024

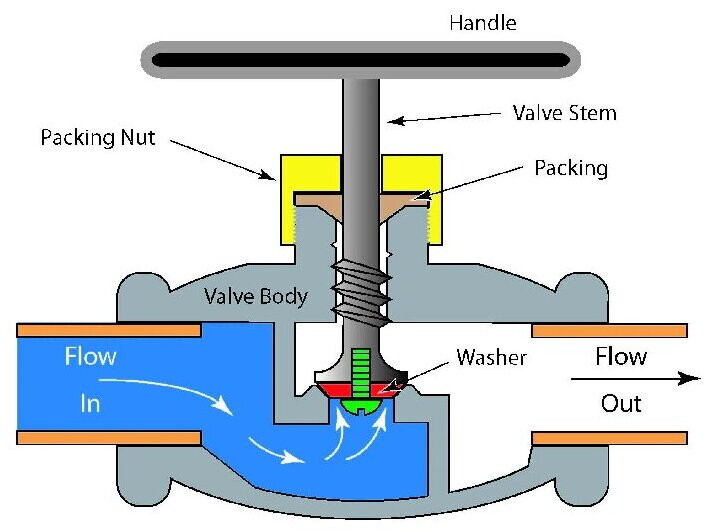

Structural Features of Globe Valve

The globe valve encompasses distinct structural elements pivotal to its operational efficacy and functionality. Here are the key structural features:

2. Superior Sealing Performance: Throughout the valve's opening and closing actions, minimal wear occurs as there is no relative sliding between the valve disc and the sealing surface of the valve body (excluding the conical sealing surface). Consequently, the globe valve achieves excellent sealing performance and boasts an extended service life.

3. Compact Design: With its relatively diminutive opening height, usually around 1/4 of the seat passage diameter, the globe valve features a compact structure, thereby conserving valuable installation space.

Its Characteristics of Operating Torque

The operating torque of the globe valve manifests distinct characteristics:

- "Low Inlet, High Outlet" Characteristic: During the initial stages of valve closure from the fully open position, the operating force must surmount resistance primarily stemming from friction between the valve stem and packing, alongside the thrust induced by the medium pressure acting on the valve disc area. As the disc descends, the pressure disparity generated by the fluid ahead and behind the disc impedes further descent, necessitating increased torque to complete the valve closure. Moreover, during valve opening, overcoming the substantial static friction torque between sealing surfaces may lead to an opening torque surpassing the closing torque.

- "High Inlet, Low Outlet" Characteristic: While the valve commences closure from the fully open position, the operating force encounters the same resistance as aforementioned. However, as the thrust from medium pressure and pressure disparity ahead and behind the disc opposes the opening direction, the operating torque demanded during the opening process significantly exceeds the closing torque.

About the Advantages and Disadvantages

Globe valves offer distinct advantages and face certain limitations, as outlined below:

Advantages:

- Simplicity and Maintenance Ease: The globe valve's straightforward design and maintenance procedures render it cost-effective and easy to manage.

- Outstanding Sealing Performance: Minimal wear on sealing surfaces ensures long-term, stable sealing performance.

- Space Efficiency: Its compact structure, characterized by a small opening height, conserves installation space.

Disadvantages:

- Installation Inconvenience: Larger structural length may pose challenges during installation.

- Labor-Intensive Operation: High opening and closing torque requirements may necessitate labor-intensive operation.

- Flow Resistance and Pressure Loss: Significant flow resistance may result in notable pressure losses.

- Flow Direction Limitation: Inability to alter flow direction due to constraints imposed by the medium flow.

- Risk of Solid Particle Entrapment: Potential for trapping solid particles in the fluid medium during valve closure requires vigilant attention.

In conclusion, while the globe valve presents a versatile solution for fluid control in industrial applications, careful consideration of its advantages and disadvantages is crucial for optimal selection and application. Its simplicity, superior sealing performance, and space efficiency render it indispensable across various industrial sectors, albeit with notable limitations and challenges that necessitate prudent management during installation and utilization.

Next: Three-Way Ball Valves: Streamlined Fluid Control Solutions

Previous: Swing Check Valves: Structure, Operation and Maintenance Guide