Trunnion Mounted Ball Valve: A Breakthrough in High-Performance Valve Technology

Dec 09, 2023

Trunnion mounted ball valve, a subtype of ball valves, stands out as robust counterparts to high-pressure ball valves, recognized as the next generation of high-performance valves. This valve is meticulously designed for application in long-distance pipelines and general industrial pipelines, with a particular focus on strength and resilience in harsh environments. Trunnion mounted ball valves excel in handling various corrosive and non-corrosive media.

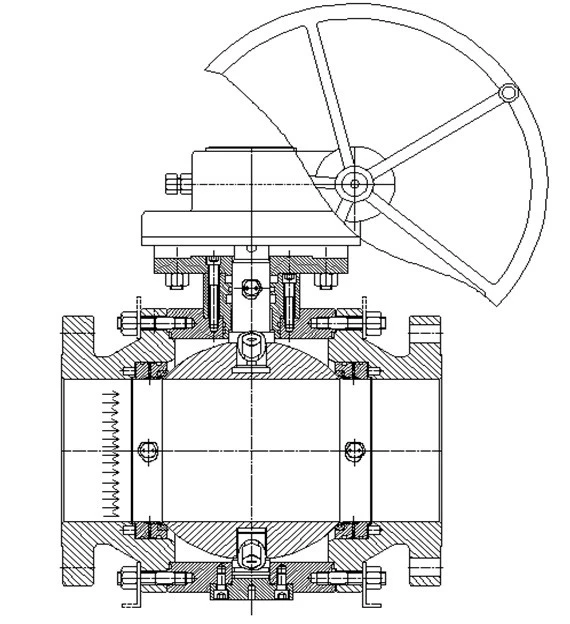

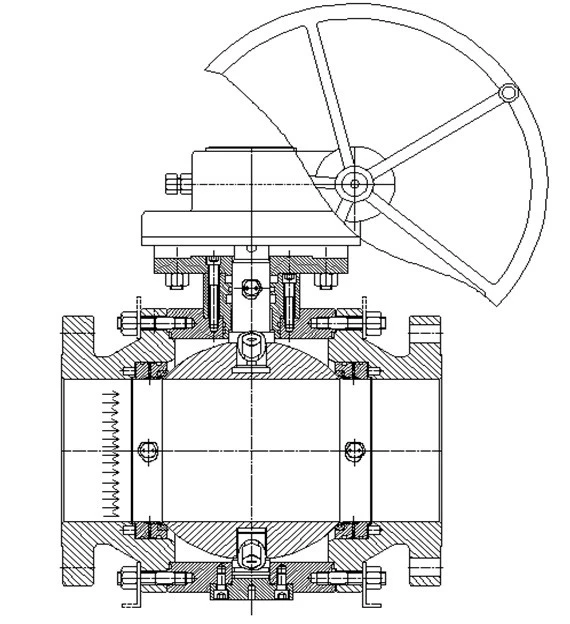

Trunnion Mounted Ball Valve Structure

Smart Design for Versatile Installation

The advanced spring pre-seat assembly in trunnion mounted ball valves possesses self-tightening characteristics, ensuring upstream sealing. With two valve seats in each direction, there are no flow direction restrictions during installation, making them bidirectional. These valves are typically installed horizontally.

Optimal Performance Under High Pressure

In comparison to floating ball valves, the fluid pressure acting on the ball during operation is entirely transferred to the bearings in trunnion mounted ball valves. This mechanism prevents the ball from moving towards the valve seat, ensuring that the valve seat does not bear excessive pressure. Consequently, trunnion mounted ball valves exhibit low torque, minimal seat deformation, stable sealing performance, and an extended service life, making them an ideal choice for high-pressure and large-diameter applications.

Advantages in Performance

In summary, trunnion mounted ball valves represent a significant advancement in valve technology, offering enhanced performance, durability, and safety features. These valves are a reliable choice for critical applications in industries where high pressure, large diameter, and extended service life are essential.

Trunnion Mounted Ball Valve Structure

- Trunnion mounted ball valves come in two types: two-piece and three-piece structures.

- The central flange is bolted, and the sealing utilizes enhanced polytetrafluoroethylene (PTFE) embedded in a stainless steel ring.

- A spring at the rear of the steel ring ensures that the valve seat remains tightly pressed against the ball, maintaining a reliable seal.

- Both upper and lower stems feature PTFE bearings, reducing friction for effortless operation.

- The bottom of the stem includes an adjusting plate, ensuring the correct position of the junction between the ball and the sealing ring.

Smart Design for Versatile Installation

The advanced spring pre-seat assembly in trunnion mounted ball valves possesses self-tightening characteristics, ensuring upstream sealing. With two valve seats in each direction, there are no flow direction restrictions during installation, making them bidirectional. These valves are typically installed horizontally.

Optimal Performance Under High Pressure

In comparison to floating ball valves, the fluid pressure acting on the ball during operation is entirely transferred to the bearings in trunnion mounted ball valves. This mechanism prevents the ball from moving towards the valve seat, ensuring that the valve seat does not bear excessive pressure. Consequently, trunnion mounted ball valves exhibit low torque, minimal seat deformation, stable sealing performance, and an extended service life, making them an ideal choice for high-pressure and large-diameter applications.

Advantages in Performance

1. Effortless Operation: Upper and lower bearings support the ball, reducing friction and eliminating excessive torque from sealing load.

2. Reliable Sealing: A PTFE single-material sealing ring in a stainless steel seat, with a rear spring for consistent pre-tightening force, maintains ongoing sealing performance even with surface wear.

3. Fire-Resistant Design: Installation of a fire-resistant sealing ring between the ball and valve seat prevents significant leakage in case of PTFE ring burning, ensuring a metal-to-metal seal.

4. Automatic Pressure Relief: If pressure in the valve chamber exceeds the spring's pre-force, the valve seat retreats from the ball, achieving automatic pressure relief; the seat then returns to its position.

5. Efficient Drainage: Equipped with upper and lower drainage holes, the valve allows leak detection and facilitates easy packing replacement and discharge of retained substances during full open or closed states, minimizing medium contamination.

2. Reliable Sealing: A PTFE single-material sealing ring in a stainless steel seat, with a rear spring for consistent pre-tightening force, maintains ongoing sealing performance even with surface wear.

3. Fire-Resistant Design: Installation of a fire-resistant sealing ring between the ball and valve seat prevents significant leakage in case of PTFE ring burning, ensuring a metal-to-metal seal.

4. Automatic Pressure Relief: If pressure in the valve chamber exceeds the spring's pre-force, the valve seat retreats from the ball, achieving automatic pressure relief; the seat then returns to its position.

5. Efficient Drainage: Equipped with upper and lower drainage holes, the valve allows leak detection and facilitates easy packing replacement and discharge of retained substances during full open or closed states, minimizing medium contamination.

In summary, trunnion mounted ball valves represent a significant advancement in valve technology, offering enhanced performance, durability, and safety features. These valves are a reliable choice for critical applications in industries where high pressure, large diameter, and extended service life are essential.

Next: A Basic Understanding of Piston Check Valves

Previous: Sealing Mechanisms in Floating and Trunnion Mounted Ball Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China