Trim Numbers of Valves

Feb 28, 2023

For API valves, the trim is normally referred to the valve's internal parts that in contact with the fluid. According to API 600 and API 602, the trim is comprised of the following generally:

a) stem;

b) body seating surface;

c) gate seating surface;

d) bushing, or a deposited weld, for the backseat and stem hole guide;

e) small internal parts that normally contact the service fluid, excluding the pin that is used to make a stem-to-gate connection (this pin shall be made of an austenitic stainless steel material).

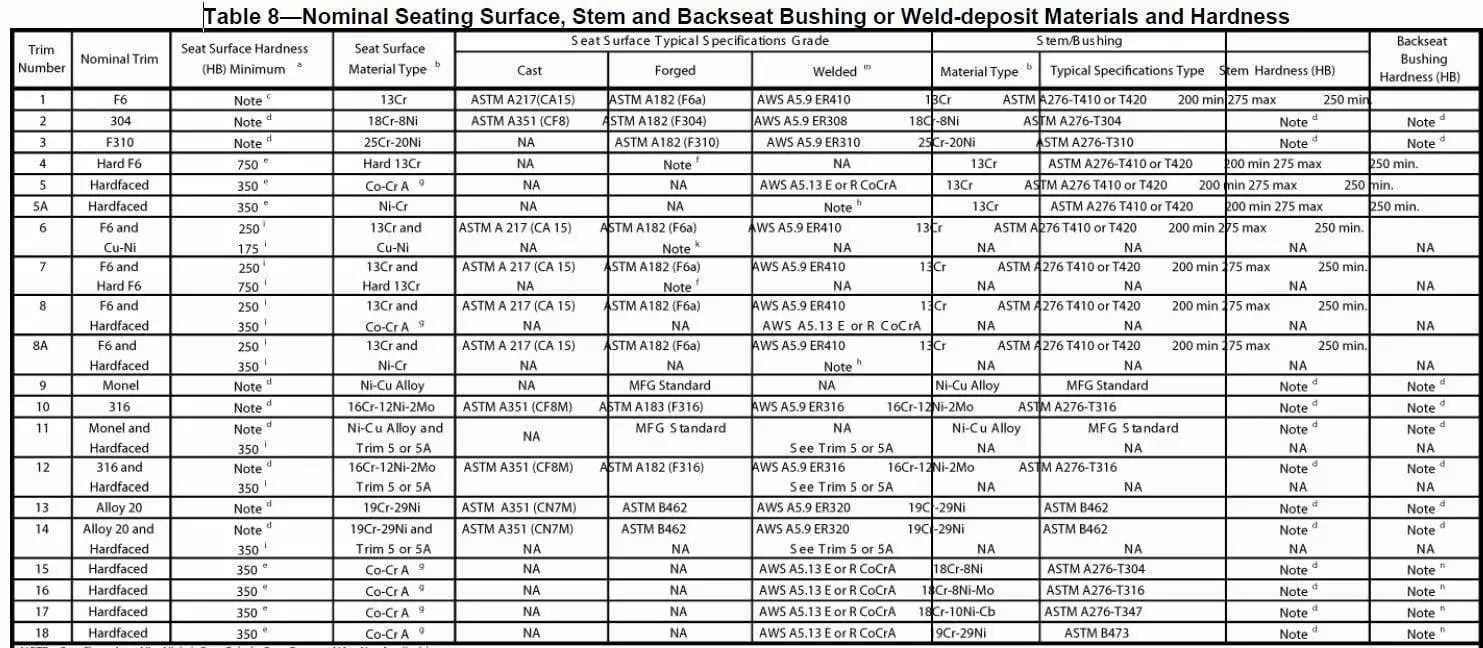

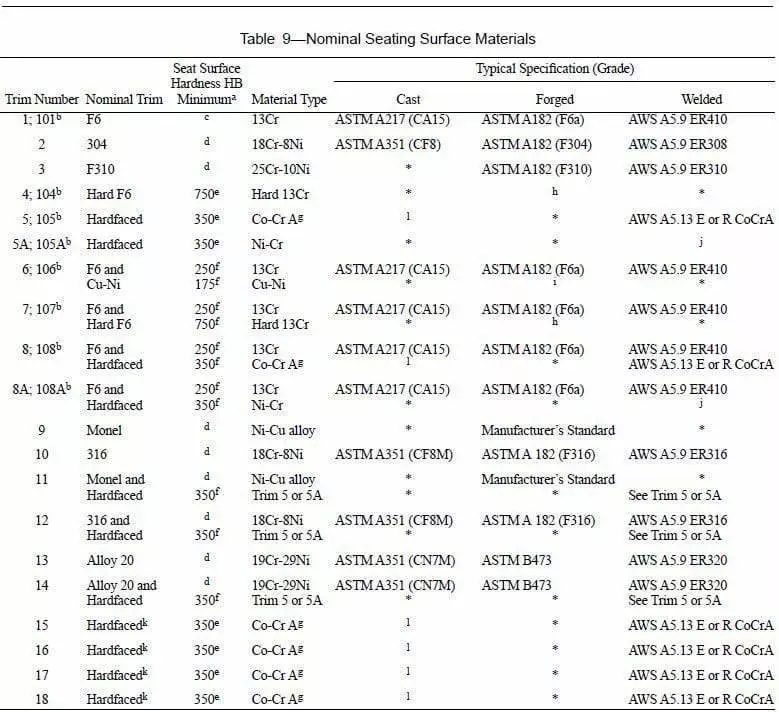

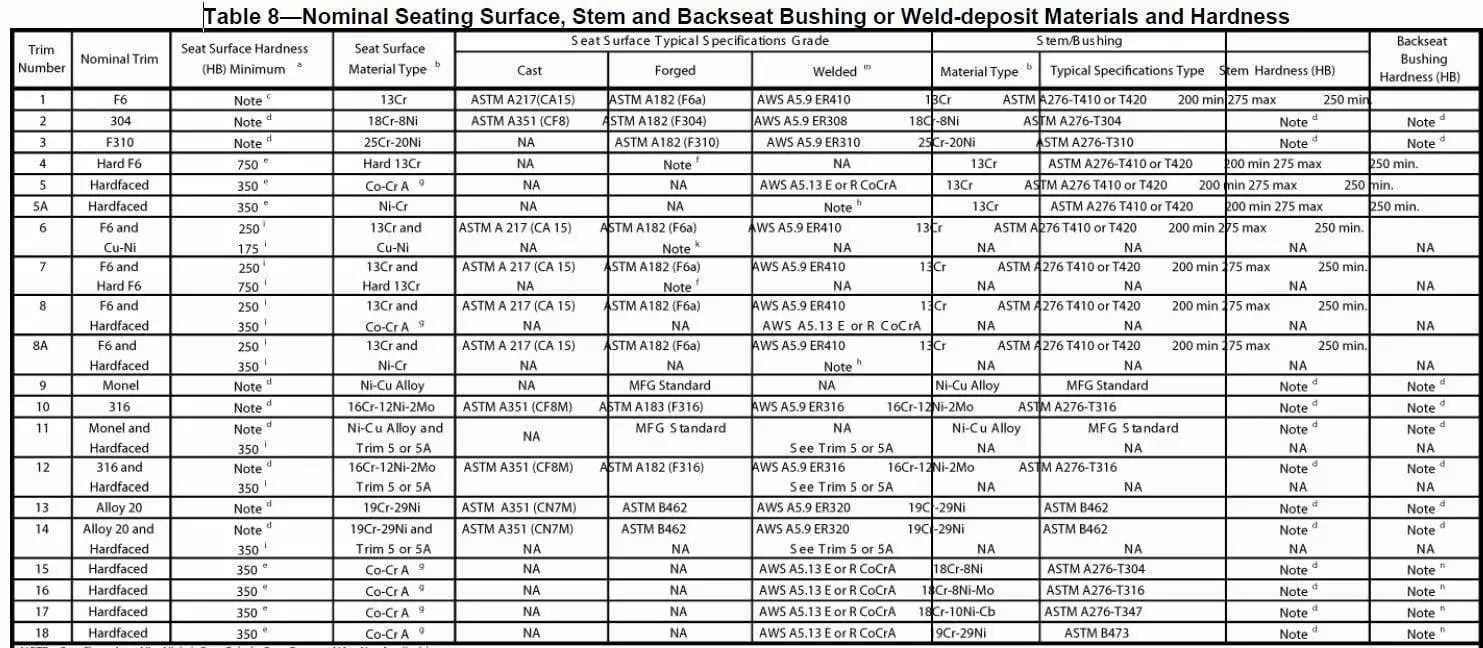

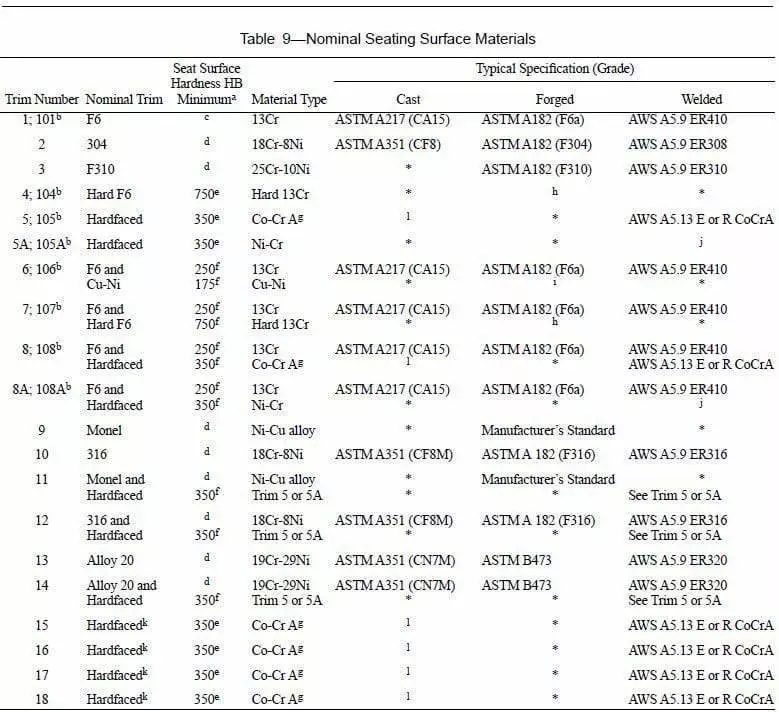

The typical trim specifications are listed in API 600 and API 602 for reference.

For valve types where overlay weld deposit is used for the seating surface, how to select the gate and seat ring base material?

The base material of the valve wedge/disc and separate body seat ring, when used, shall be of a nominal material composition equal to the body or to that of the stem material; except for wedge or disc material made of solid trim material.

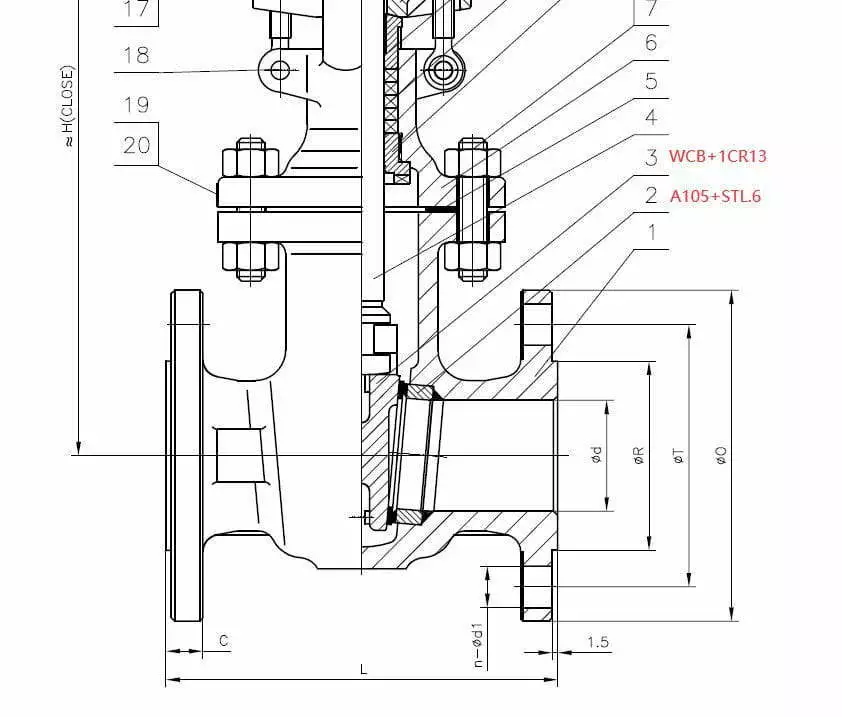

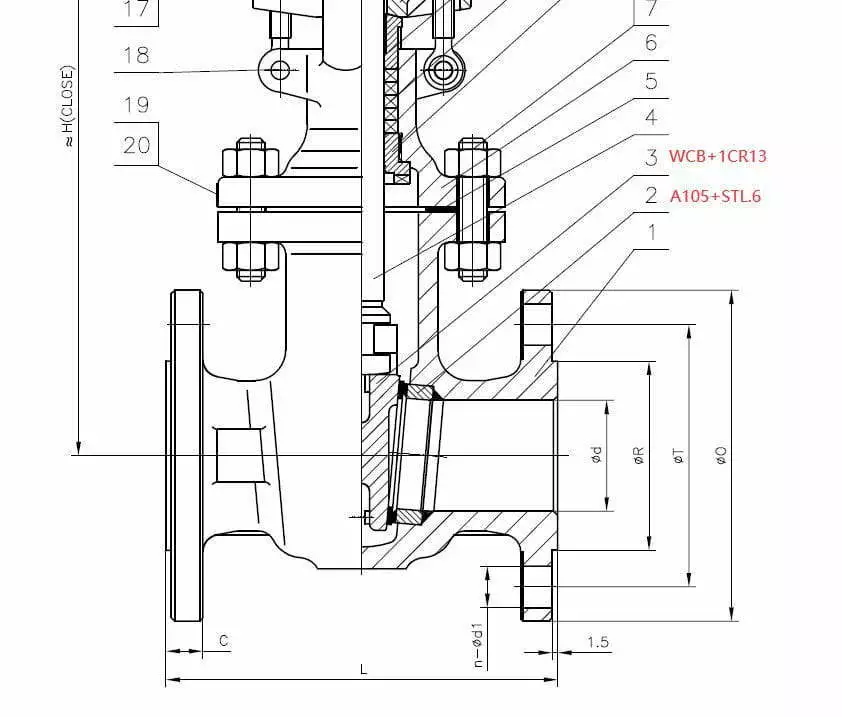

For example, the casting gate valve 2" 150 LB in WCB body and trim number 8.

Stem should be ASTM 182 F6A,

The gate seating surface is 13Cr.

The gate base material is ASTM A216 WCB (Equal to the valve body).

The seat ring surface is STL.6 Overlay (CoCr-A).

The seat ring base material is ASTM A105 (Equal to the valve body).

But when it's solid trim, for example, API 602 forged valve, 1" 800 LB gate valve in A105 body and trim number 8. The wedge will be A182 F6A and the seta ring to be A182 F6A+STL.6 instead.

a) stem;

b) body seating surface;

c) gate seating surface;

d) bushing, or a deposited weld, for the backseat and stem hole guide;

e) small internal parts that normally contact the service fluid, excluding the pin that is used to make a stem-to-gate connection (this pin shall be made of an austenitic stainless steel material).

The typical trim specifications are listed in API 600 and API 602 for reference.

For valve types where overlay weld deposit is used for the seating surface, how to select the gate and seat ring base material?

The base material of the valve wedge/disc and separate body seat ring, when used, shall be of a nominal material composition equal to the body or to that of the stem material; except for wedge or disc material made of solid trim material.

For example, the casting gate valve 2" 150 LB in WCB body and trim number 8.

Stem should be ASTM 182 F6A,

The gate seating surface is 13Cr.

The gate base material is ASTM A216 WCB (Equal to the valve body).

The seat ring surface is STL.6 Overlay (CoCr-A).

The seat ring base material is ASTM A105 (Equal to the valve body).

But when it's solid trim, for example, API 602 forged valve, 1" 800 LB gate valve in A105 body and trim number 8. The wedge will be A182 F6A and the seta ring to be A182 F6A+STL.6 instead.

Next: What is difference between DBB and DIB ball valves?

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China