Three-Way Ball Valves: Streamlined Fluid Control Solutions

Feb 27, 2024

Three-way ball valves are indispensable components in industrial and pipeline systems, offering efficient control over fluid flow. With their simple yet robust design, these ball valves play a crucial role in various industries by facilitating fluid distribution, diversion, and shut-off operations. Understanding their structure, working principles, and advantages is essential for optimizing their performance within complex piping networks.

The working principle of the three-way ball valve is simple and clear:

- Opening Process: By rotating the handwheel counterclockwise, the stem rises and causes the ball to detach from the seat, then starts rotating to the fully open position, allowing the medium to flow smoothly.

- Closing Process: By rotating the handwheel clockwise, the stem descends and gradually presses the ball tightly against the seat, ultimately achieving complete sealing and stopping the flow of the medium.

Structure and Types

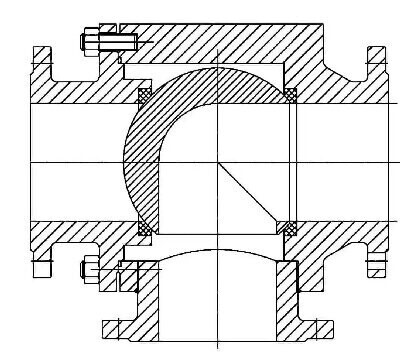

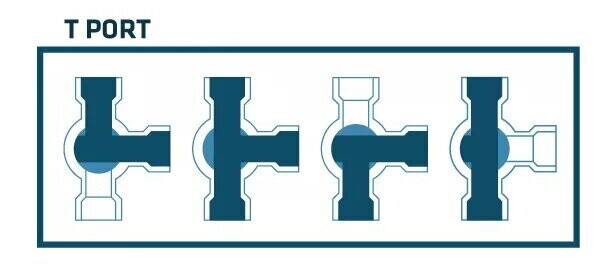

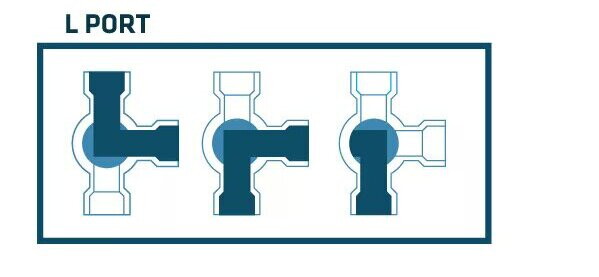

The structure of the three-way ball valve is relatively simple, generally consisting of a ball, seat, stem, and operating device. According to different forms, it can be divided into T-type and L-type:

- T-type: It can achieve the interconnection of three pipelines and shut off the third channel, suitable for diversion and convergence.

- L-type: Connecting two orthogonal pipelines, it cannot simultaneously maintain the interconnection of the third pipeline, mainly used for distribution.

Function and Advantages

The main functions of the three-way ball valve include cutting off, distributing, and changing the flow direction of the medium. Compared to other valves, it has the following advantages:

1. Light and Convenient Switching: Through simple rotation, it achieves the smooth flow or shut-off of the medium, making operation easy and convenient.

2. Simple Structure: Designed with an integrated structure, it reduces the number of components, thereby enhancing reliability and stability.

3. Easy Maintenance: With a simple structure, maintenance and replacement of sealing rings and other parts are quick and convenient, minimizing downtime.

4. Wide Range of Applications: From micro to large sizes, it is suitable for various mediums and working environments.

Installation and Maintenance Precautions

When installing and maintaining the three-way ball valve, attention should be paid to the following points:

- Leave enough space for the handle to rotate, ensuring convenient operation.

- Avoid using it for throttling operations to prevent affecting the valve's performance and lifespan.

- Ball valves with transmission mechanisms should be installed vertically to ensure their normal operation and long-term stability.

In conclusion, three-way ball valves represent a cornerstone in fluid control systems, owing to their versatility, reliability, and ease of operation. Their straightforward structure and efficient functionality make them indispensable assets across a wide range of industries. By adhering to proper installation and maintenance practices, these valves ensure smooth and reliable operation, contributing to enhanced efficiency and safety in industrial processes and fluid transportation systems.

Next: Forged Stainless Steel Ball Valves: Advancing Pipeline Technology

Previous: Understand the Principle and Features of Globe Valve

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China