Three Common Wedge Gate Valve Disc Structures

Sep 11, 2024

On this page

Wedge gate valves are widely used in industrial piping systems due to their simple structure and reliable operation. The gate disc, as the core component of the wedge gate valve, directly influences the valve's sealing performance and applicability. There are three common structures for wedge gate discs: flexible wedge disc, solid wedge disc, and split wedge disc. Each structure has unique advantages and suitable applications, playing a crucial role in the valve's overall performance and operation. Understanding the characteristics, advantages, disadvantages, and application scenarios of these three disc structures helps in selecting the appropriate valve configuration for specific working conditions. Below, we explore the design principles, advantages, and limitations of each wedge gate disc structure in detail.

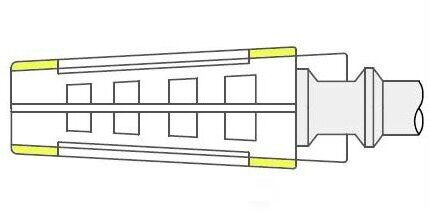

The Flexible Wedge Disc stands out for its simple structure and excellent sealing performance. It features a central cantilever beam and a ring groove design, providing the disc with a certain degree of elasticity. This allows the disc to self-adjust when the valve is closed, compensating for manufacturing errors and ensuring a tight seal. Let's delve into the design features, advantages, and practical applications of the Flexible Wedge Disc.

The Flexible Wedge Disc has a straightforward yet effective structural design. The disc is supported on a cantilever beam in the center, with sealing surfaces on both sides featuring a ring groove on the vertical dividing plane. This groove imparts elasticity to the disc. When the valve closes, the disc undergoes slight deformation, compensating for manufacturing errors and achieving a tight fit with the valve seat.

High Adaptability: The Flexible Wedge Disc design can effectively handle changes in medium temperature, reducing the risk of the disc being wedged due to temperature fluctuations. It maintains good sealing performance despite temperature changes and pipe deformation.

Lower Processing Precision Requirements: Due to its elastic design, the wedge angle's processing precision requirements are relatively low, simplifying the manufacturing process and reducing costs.

Self-Compensating Capability: Through elastic deformation, the Flexible Wedge Disc can compensate for fit gaps caused by manufacturing errors, ensuring a reliable seal.

Solid Particle Limitation: Not suitable for media with a large amount of solid particles, as particles may accumulate in the ring groove, affecting the disc's elasticity and sealing performance.

Closing Torque Limitation: To prevent exceeding the disc's elastic deformation range, the closing torque should not be too high, necessitating a limit mechanism to control the disc's stroke.

The Flexible Wedge Disc is widely used in various pressure and temperature ranges for medium and small diameter valves, especially in environments with significant temperature changes.

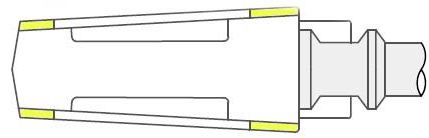

The Solid Wedge Disc is a solid single-piece structure with a simple design but requires high-precision processing. Its structure does not accommodate changes in valve seat alignment due to pipeline loads or thermal fluctuations, thus requiring very precise machining of the sealing surface's wedge angle. This disc type is relatively complex in manufacturing and maintenance, yet its cost-effectiveness and widespread application make it popular in specific scenarios.

Cost-Effectiveness: The Solid Wedge Disc has a simple structure, resulting in lower manufacturing costs, making it suitable for budget-conscious projects.

Small Diameter Applications: Ideal for small diameter valves (DN50 or NPS2) and performs well in lower “pressure-temperature” conditions.

High Wear Risk: The sealing surfaces are prone to wear during operation, affecting sealing effectiveness and valve lifespan.

Temperature Sensitivity: Temperature fluctuations can easily cause the disc to be wedged, impacting normal valve operation.

Usage Limitation: Generally not recommended for applications exceeding 121°C (250°F).

The Solid Wedge Disc is best suited for low-temperature and small-diameter valves, particularly in scenarios requiring cost-effectiveness and ease of maintenance. Understanding these characteristics helps in making informed decisions when selecting gate valves.

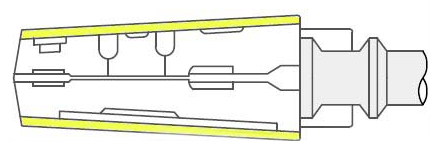

The Split Wedge Disc structure consists of two discs connected via a spherical top pivot, forming a wedge shape. This design allows the discs to automatically adjust their angle during operation to achieve a good fit with the valve seat. The wedge angle of the Split Wedge Disc is automatically adjusted by the central spherical pivot, reducing the precision requirements for machining the sealing surface's wedge angle.

Self-Adjusting Capability: Due to the spherical pivot design, the Split Wedge Disc can automatically adjust the wedge angle, adapting to temperature changes and avoiding the issue of the disc being wedged due to temperature variations.

Maintenance Convenience: After wear on the sealing surfaces, compensation can be made by adding gaskets at the pivot, simplifying the maintenance process.

High Durability: Suitable for high-temperature, high-pressure, or large-diameter applications, capable of withstanding significant pressure and temperature fluctuations.

Complex Structure: The Split Wedge Disc's complex structure with multiple parts may lead to increased manufacturing and maintenance costs.

Not Suitable for Viscous Media: Due to the movable connection of the discs, long-term corrosion may lead to disc detachment, making it unsuitable for viscous media.

The Split Wedge Disc is applicable for valves ranging from DN50 to DN600 (NPS12 to NPS24) and is widely used in pipelines for water and steam. The materials used include carbon steel, chromium-molybdenum steel, stainless steel, duplex stainless steel, and nickel alloys, with operating temperature ranges up to -196°C to 816°C.

Different types of wedge gate discs each have their own characteristics and suitable applications. The Flexible Wedge Disc is ideal for environments with significant temperature fluctuations due to its self-compensating and adaptable nature. The Solid Wedge Disc, with its cost-effectiveness, is suitable for low-temperature and small-diameter applications. The split wedge disc, with its self-adjusting capability and durability, is best for high-temperature, high-pressure, and large-diameter conditions. When selecting the appropriate wedge gate disc structure, it is essential to consider working conditions, medium properties, and valve cost and maintenance requirements to ensure long-term stable operation.

Next: Key Design and Features Wafer Check Valves

Previous: Axial Flow Check Valve: Structural Analysis and Applications

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China