The Significance of Angle Globe Valves in Industrial Processes

Mar 07, 2024

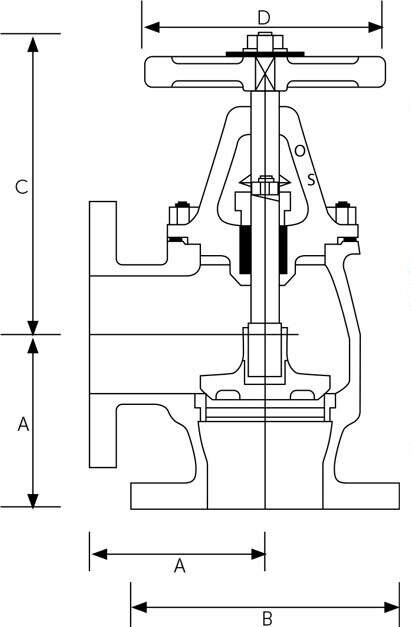

Angle globe valves stand as indispensable components in various industrial processes, offering crucial functionalities such as flow regulation, pressure control, and fluid interruption. Renowned for their efficiency and reliability, these globe valves have garnered significant attention and widespread adoption across diverse industries. In this context, it's essential to delve into their advantages to appreciate their importance in modern engineering applications.

Working Principle

The angle globe valve operates with a plug-shaped valve disc, featuring flat or conical sealing surfaces. The valve disc moves linearly along the fluid's centerline. Valve stems move in two forms: lift rod or lift-and-rotate rod. In the former, the valve stem moves vertically while the handwheel remains stationary; in the latter, the handwheel rotates with the valve stem, with the nut on the valve body. Angle globe valves are strictly for full open or close positions, incapable of adjustment or throttling. The closing force overcomes stem-packing friction and medium pressure thrust.

Major Advantages

Angle globe valves offer several advantages over other types of valves due to their design and functionality:

1. High Sealing Performance

The 90-degree angle sealing design of the angle globe valve ensures that the fluid can be evenly distributed on the sealing surface as it flows through the valve, thereby improving the sealing performance of the valve. This enables the globe valve to withstand higher working pressures and a wider range of temperatures, suitable for high-pressure, high-temperature, and high-viscosity media.

2. Simple Structure, Easy Installation

Angle globe valves have a simple structure, small size, and light weight, making them easy to install and maintain. Their valve discs and seats are usually made of metal materials, with excellent wear resistance and corrosion resistance, enabling the valve to operate stably in harsh working environments.

3. Good Flow Control Performance

In the closed position, the valve disc of the angle globe valve forms a small passage with the valve seat, effectively controlling the flow of the medium. When the valve is opened, the sealing surface gradually expands, allowing the fluid to pass smoothly through the valve. Therefore, globe valves have good flow control performance.

The 90-degree angle sealing design of the angle globe valve ensures that the fluid can be evenly distributed on the sealing surface as it flows through the valve, thereby improving the sealing performance of the valve. This enables the globe valve to withstand higher working pressures and a wider range of temperatures, suitable for high-pressure, high-temperature, and high-viscosity media.

2. Simple Structure, Easy Installation

Angle globe valves have a simple structure, small size, and light weight, making them easy to install and maintain. Their valve discs and seats are usually made of metal materials, with excellent wear resistance and corrosion resistance, enabling the valve to operate stably in harsh working environments.

3. Good Flow Control Performance

In the closed position, the valve disc of the angle globe valve forms a small passage with the valve seat, effectively controlling the flow of the medium. When the valve is opened, the sealing surface gradually expands, allowing the fluid to pass smoothly through the valve. Therefore, globe valves have good flow control performance.

Applications in Industry

Due to their excellent performance, angle globe valves have been widely used in industries such as petroleum, chemical, power generation, water conservancy, and construction. For example, in the petroleum industry, globe valves are used to control the pressure and flow of oil wells; in the chemical industry, they are used to regulate and cut off corrosive media; in the power generation industry, they are used to regulate and cut off high-temperature and high-pressure steam; and in the water conservancy industry, they are used to control the distribution and discharge of water resources.

In conclusion, angle globe valves are indispensable assets in industrial operations, offering precise flow control, superior sealing capability, versatility, and robust construction. Their myriad advantages contribute to enhanced efficiency, reliability, and safety across industries. As technology advances and industrial processes evolve, angle globe valves continue to ensure optimal performance and operational integrity, making them vital components in various applications.

Next: Solutions and Preventive Measures for Managing Valve Leakage

Previous: Maintenance Guide for Pneumatic Ball Valve Seal Replacement

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China