TAT Qualification Range for valves - MESC SPE 77-300 (2022)

Jan 06, 2024

The MESC SPE covers the requirements and methods for evaluating the performance of industrial valves when they are exposed to the limits of their design conditions. The performance requirements establish limits on the acceptability of a valve, regardless of size or pressure rating.

The MESC SPE 77-300 specifies type acceptance testing requirements and a type acceptance test method for confirming the seat sealing, fugitive emission, and operating torque capability of a valve under pressure, during and after mechanical and thermal cycling.

The MESC SPE is edited by SHELL by now widely used for more end users as a strict quality control from prototype design verification.

How to select the tested valve and what's the qualification range?

The qualification can be extended by Size and Pressure

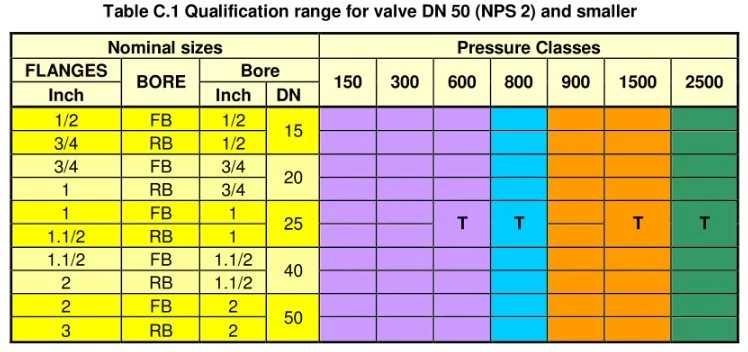

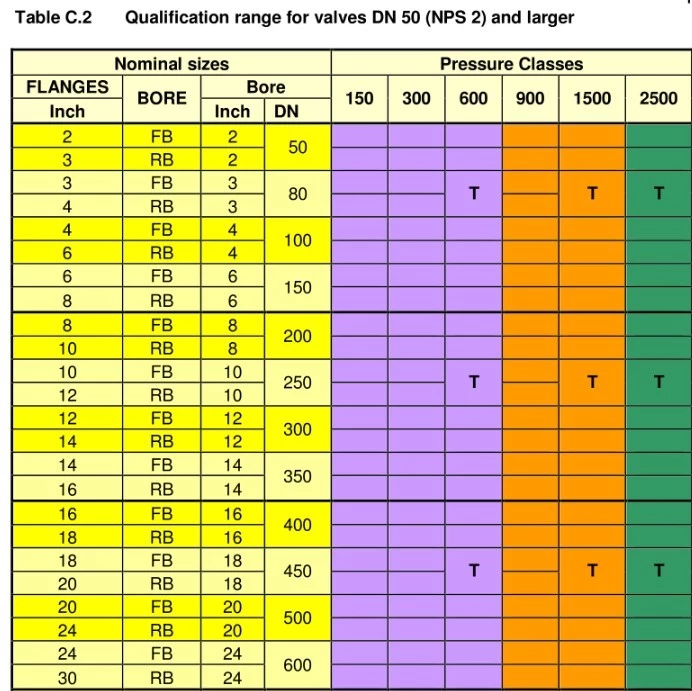

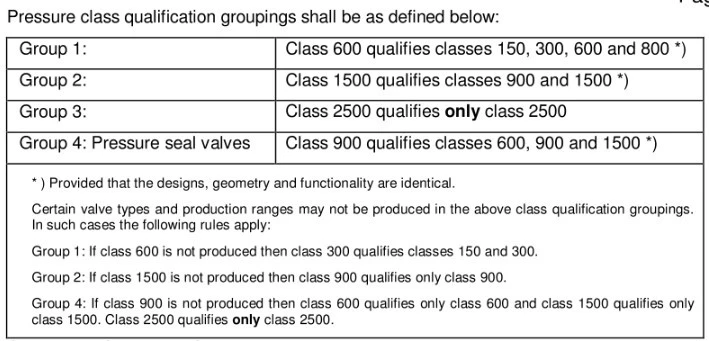

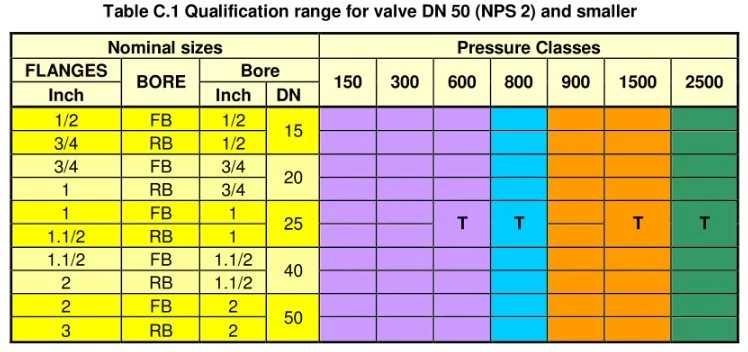

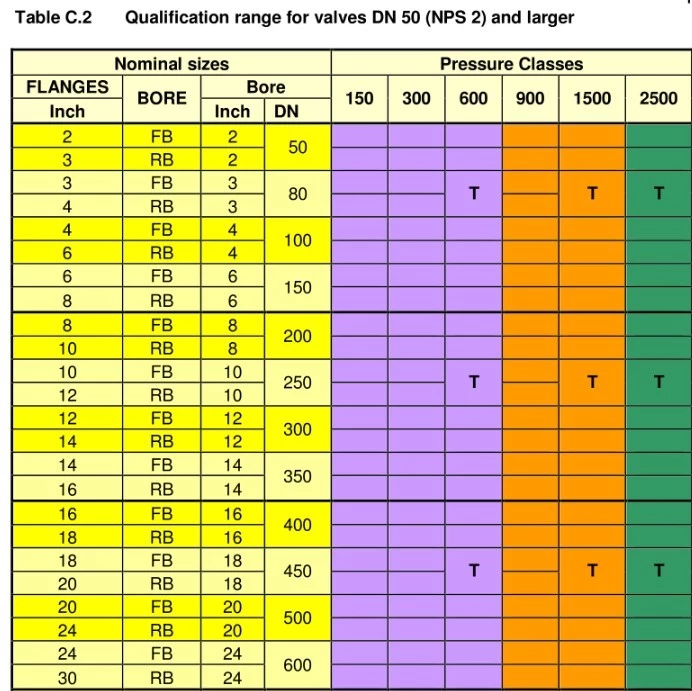

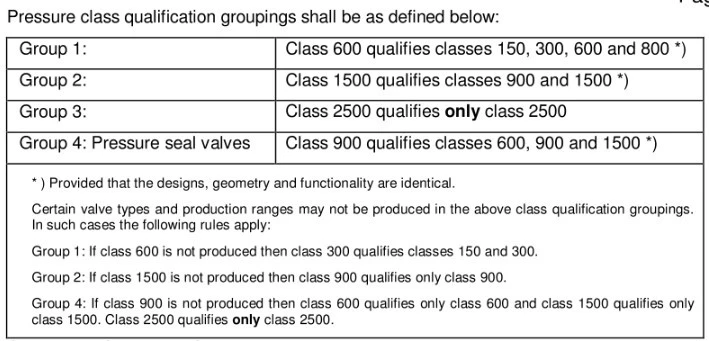

As a general rule, when a valve has been successfully tested, it will qualify nominal valve sizes — 1 size smaller and 2 sizes larger, based on the size of the internal flow bore diameter. For small-size valves ranging from DN 15 (NPS ) up to and including DN 50 (NPS 2), an exception has been made to allow any valve in that range to qualify the full range, e.g. successful testing of a DN 25 (NPS 1) valve size qualifies DN 15 (NPS ) through to DN 50 (NPS 2) - refer to TableC.1.

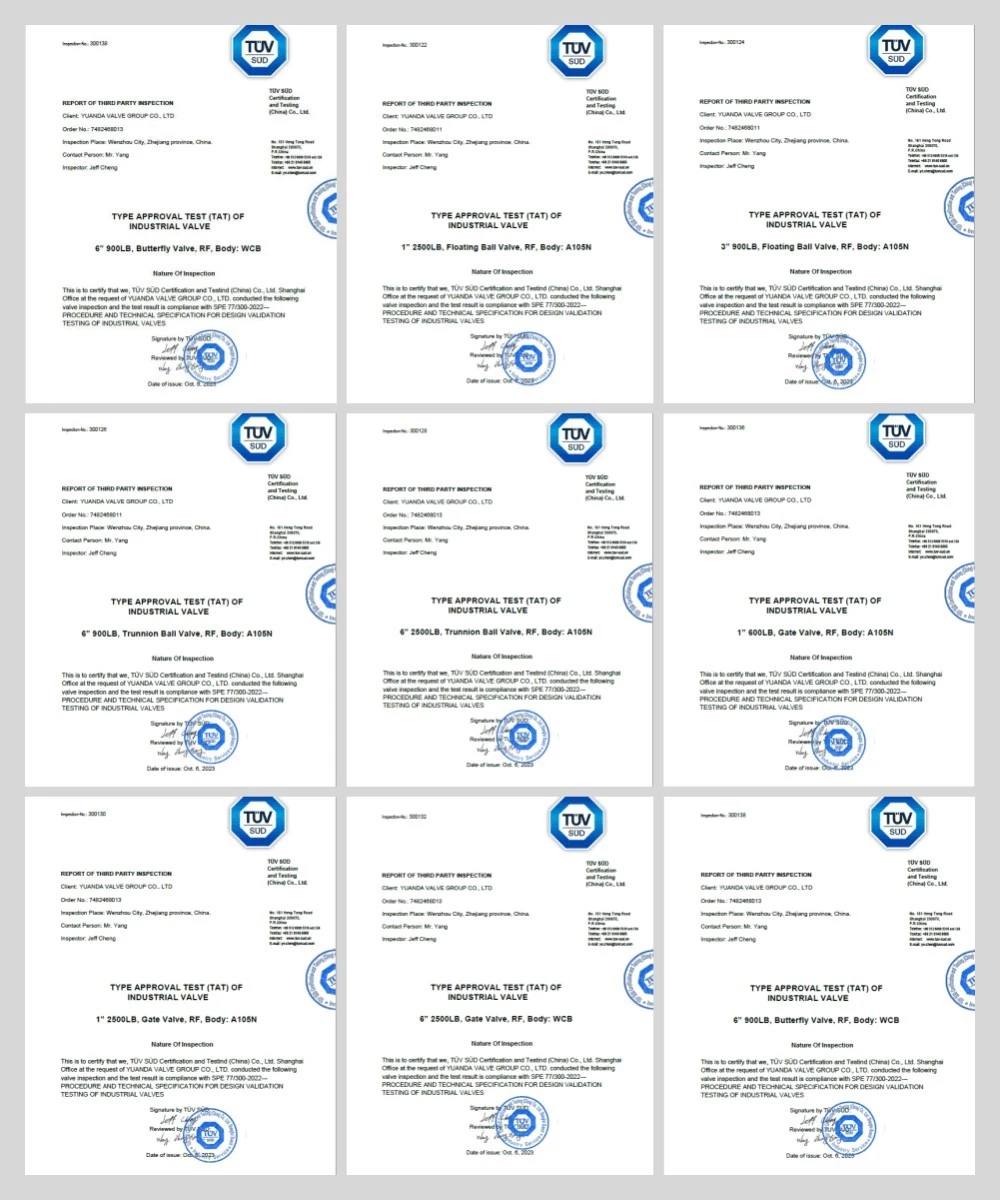

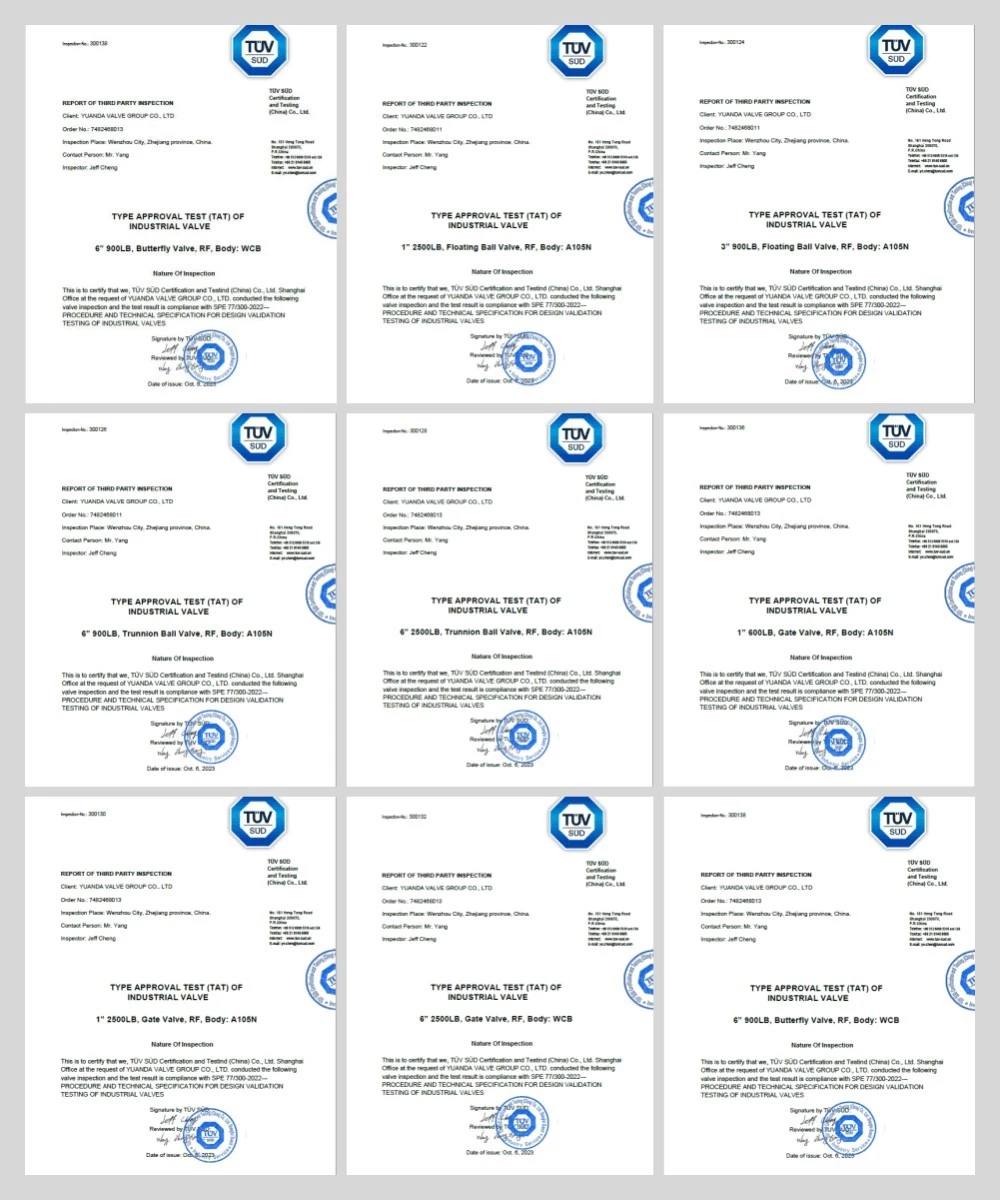

Bosseal Valve supplies Ball Valves, GGC Valves, and Butterfly Valves, which have successfully passed the type approval test according to MESC SPE 77-300 (2022)

Bosseal Valve is TAT qualified valve manufacturer, for any technical or commercial support please consider our teams at [email protected]

The MESC SPE 77-300 specifies type acceptance testing requirements and a type acceptance test method for confirming the seat sealing, fugitive emission, and operating torque capability of a valve under pressure, during and after mechanical and thermal cycling.

The MESC SPE is edited by SHELL by now widely used for more end users as a strict quality control from prototype design verification.

How to select the tested valve and what's the qualification range?

The qualification can be extended by Size and Pressure

As a general rule, when a valve has been successfully tested, it will qualify nominal valve sizes — 1 size smaller and 2 sizes larger, based on the size of the internal flow bore diameter. For small-size valves ranging from DN 15 (NPS ) up to and including DN 50 (NPS 2), an exception has been made to allow any valve in that range to qualify the full range, e.g. successful testing of a DN 25 (NPS 1) valve size qualifies DN 15 (NPS ) through to DN 50 (NPS 2) - refer to TableC.1.

Bosseal Valve supplies Ball Valves, GGC Valves, and Butterfly Valves, which have successfully passed the type approval test according to MESC SPE 77-300 (2022)

Bosseal Valve is TAT qualified valve manufacturer, for any technical or commercial support please consider our teams at [email protected]

Next: Chemical and Mechanical Requirements for Carbon Steel - ASTM A216 WCB

Previous: API 607 Fire Safe Qualification Range for Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China