Structure and Features of the Tilting Disc Check Valve

Sep 30, 2024

On this page

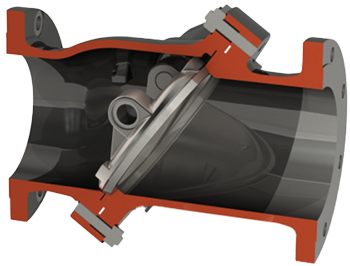

In modern industry, the safety and efficiency of fluid control systems are crucial. As one of the key components, check valves play a vital role in preventing fluid backflow and protecting equipment and system operations. Among these, the tilting disc check valve has gained significant attention due to its unique design and outstanding performance. This valve features an innovative tilting disc structure that ensures stable fluid flow in pipelines through effective sealing and rapid response capabilities. This article will explore the structural characteristics, working principles, performance advantages, and diverse applications of the tilting disc check valve.

The working principle of the tilting disc check valve primarily relies on the fluid's flow rate and gravity. When fluid flows, the valve disc opens due to the pressure of the fluid; conversely, when the fluid pressure decreases or flows in reverse, gravity prompts the valve disc to close quickly. This automatic operation allows the tilting disc check valve to function reliably under various working conditions. The load and tightness of the seat seal are closely related to the back pressure, making it essential to select the appropriate nominal diameter of the check valve based on the fluid state and pipeline design.

The structural design of the tilting disc check valve forms the foundation of its high performance, particularly its unique features in sealing, flexibility, and durability, providing significant advantages in fluid control. The precise fit between the valve disc and seat not only ensures effective sealing and quick response but also greatly reduces friction and wear, extending the valve's service life.

The core components of the tilting disc check valve are the valve disc and seat, whose design is critical for achieving efficient sealing and rapid opening and closing. The disc is shaped to tilt and is mounted on a valve shaft, allowing it to pivot and align with the seat surface. This design enables the valve disc to closely fit the seat when closed, forming an effective seal. When the valve disc tilts down and seals tightly against the seat, it closes; during opening, it rises from the seat.

The seat is designed with a specialized floating, elastic metal hard seal that allows for automatic adjustment and alignment with the valve disc. The sealing surface of the seat is part of a slanted conical shape, forming a sealing line that approximates an elliptical curve. The angle between this curve's plane and the valve flow path centerline is 60°, and the eccentric angle between the long axis center of the elliptical sealing line and the cone's axis is between 15° and 20°. This structure ensures that the valve disc closes with minimal impact and collision, achieving efficient sealing.

The tilting disc check valve features a three-eccentric design, where the axis of the valve disc's rotation is offset from the axis of the cone. This design allows the valve disc to move in a pendulum-like motion, reducing friction and wear, thus extending the valve's lifespan. The contact surface between the disc and the metal seat can quickly seal without the need for external force, ensuring the system's reliability and stability.

In the event of fluid backflow, the valve disc can quickly reach the closed position, minimizing impact. The short travel distance of the tilting disc check valve's disc allows it to respond rapidly to changes in fluid pressure, providing efficient backflow prevention. This feature is essential for protecting pipeline systems from damage caused by backflow.

The design and structure of the tilting disc check valve not only ensure its reliability in fluid control but also bring various significant performance advantages. These include quick closure, low flow resistance, automatic adjustment, and wear resistance, making the tilting disc check valve excel in many applications.

The design of the tilting disc check valve allows the disc to operate over a short distance, enabling it to quickly reach the seat position and reducing impact during closure. This characteristic makes the tilting disc check valve perform exceptionally well in conditions where frequent opening and closing occur.

When opened, the tilting disc check valve presents minimal resistance to fluid flow, allowing for high flow rates with low resistance. This feature makes it particularly suitable for applications that require large flow volumes, effectively enhancing the system's energy efficiency.

The tilting disc check valve has the capability for automatic adjustment, opening and closing based on fluid flow rate and pressure, thereby reducing the need for manual intervention and enhancing the system's level of automation.

With minimal friction contact between the valve disc and seat, the tilting disc check valve exhibits strong wear resistance, allowing it to operate stably in harsh conditions. This durability extends its service life and reduces maintenance costs.

The tilting disc check valve, with its unique structural design and superior performance, has become an important component in fluid control. With features like quick closure, low flow resistance, and automatic adjustment, this valve excels in various industrial applications. Understanding the structure and working principle of the tilting disc check valve helps make informed decisions when designing and selecting fluid control equipment, thereby enhancing the safety and reliability of the system.

Next: Industrial Valve Sealing Surface Wear and Repair

Previous: Valve Stem Sealing: Principles, Structures & Applications

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China