Soft Seal Material Options for Ball Valves

Feb 28, 2023

This article is a general guideline for soft seal material selection for your unique applications, and customers are responsible for materials of construction being compatible with their valve application. Please consult Bosseal for details if you need further technical support.

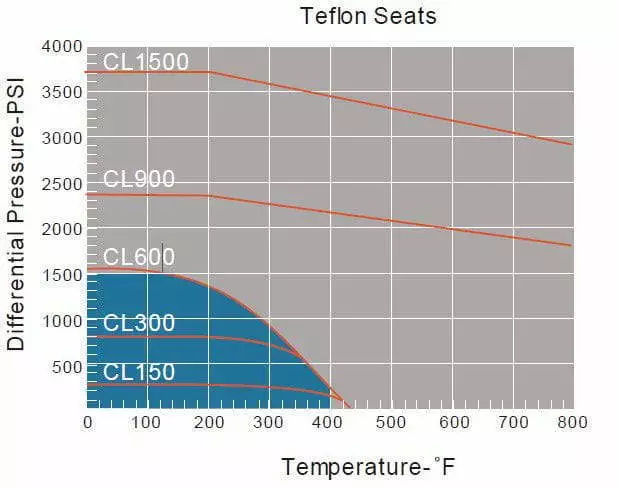

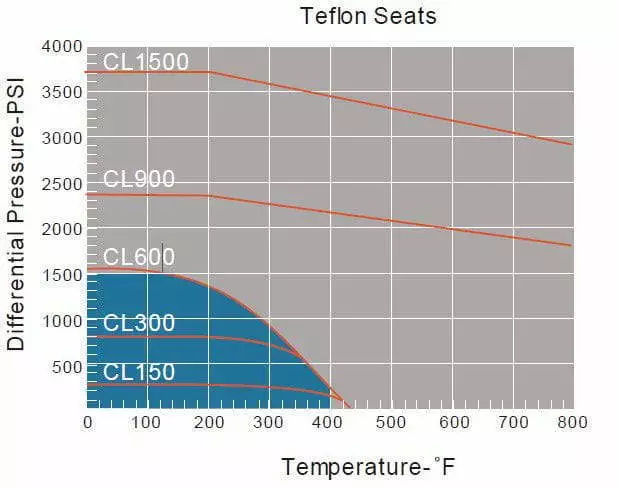

PTFE (100% Polytetrafluoroethylene)

Commonly referred to as DuPont’s Teflon®, PTFE is a thermoplastic fluoropolymer that consists of Carbon and Fluorine. This structure allows PTFE to be non-reactive to many chemicals and applied to severe chemical environments. PTFE is ideal for low-cycle life applications. Do not use in molten alkali metal and molten Fluorine applications.

Temperature Range: -50°F to 400°F

Max Pressure at Room Temperature: 1000 psi

Color: White

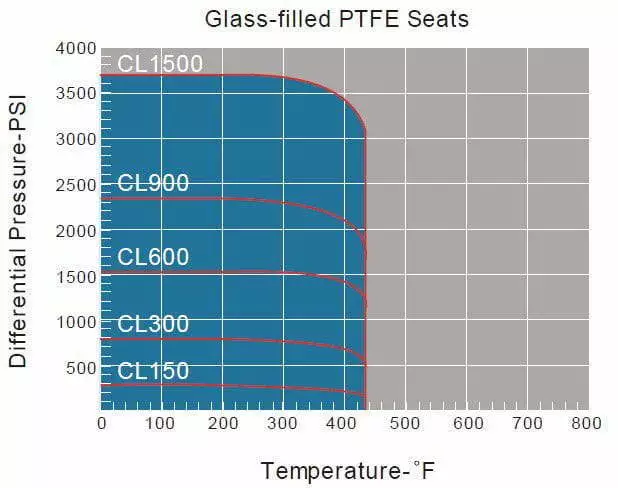

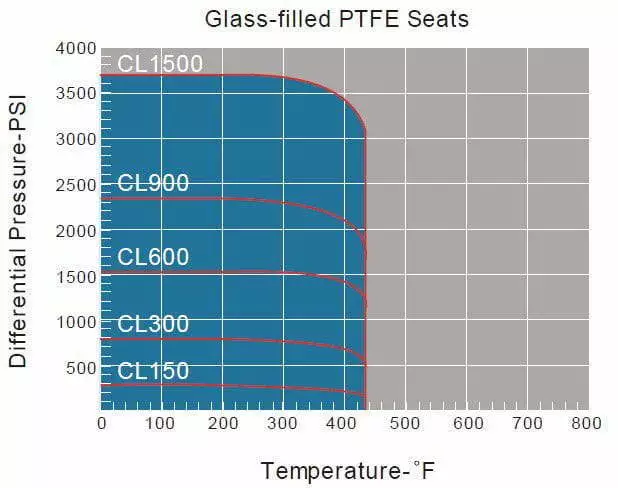

RPTFE (Glass Filled)

RPTFE has improved wear and abrasion resistance over PTFE while maintaining its chemical compatibility. Its versatile temperature characteristics allow RTFE to be used in saturated steam applications. This seat should not be used in caustic (sodium hydroxide, potassium hydroxide, etc.) service.

Temperature Range: -50°F to 450°F

Max Pressure at Room Temperature: 2000 psi

Color: Off-White

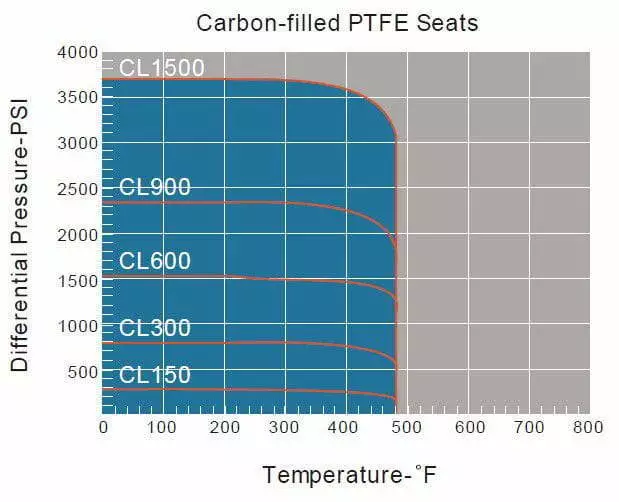

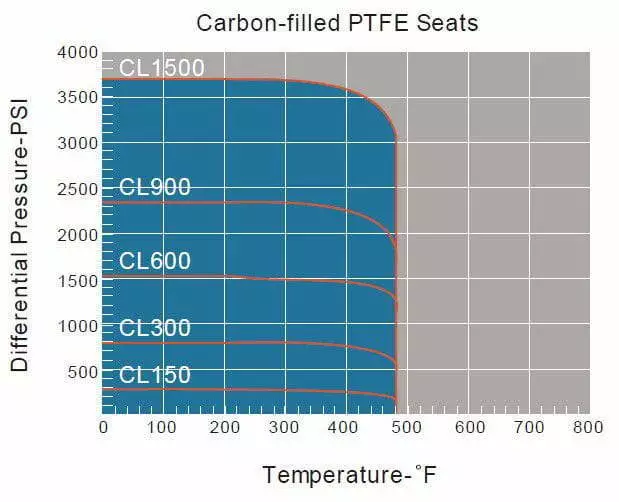

RPTFE (Carbon Filled)

Carbon-filled RPTFE is used for low-pressure steam applications, and abrasive, and slurry services. It offers comparable chemical resistance to PTFE.

Temperature Range: -50°F to 480°F

Max Pressure at Room Temperature: 2000 psi

Color: Black

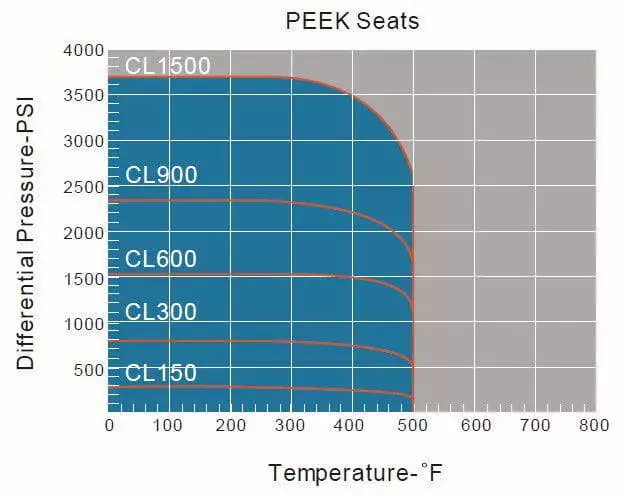

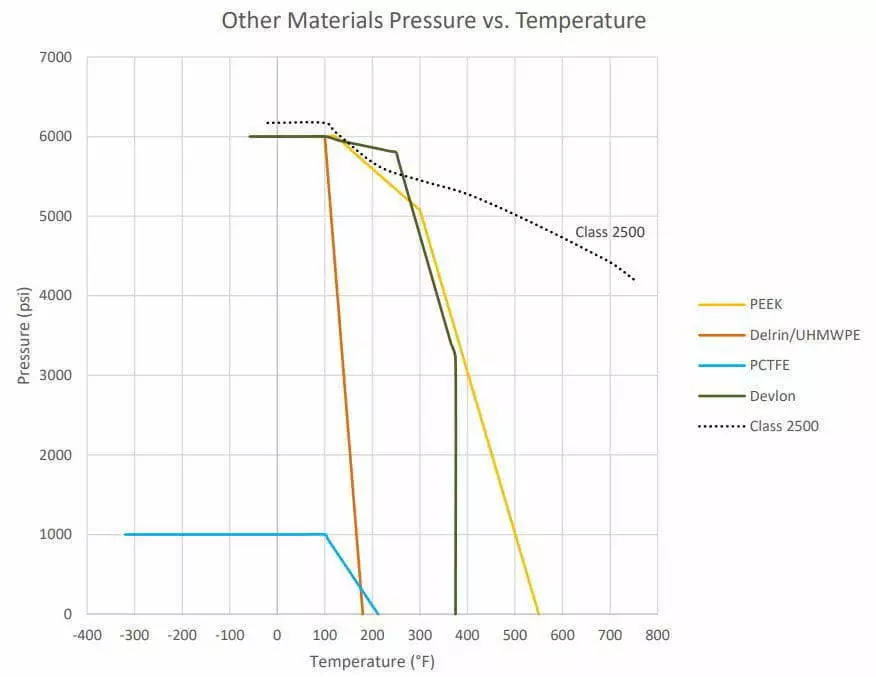

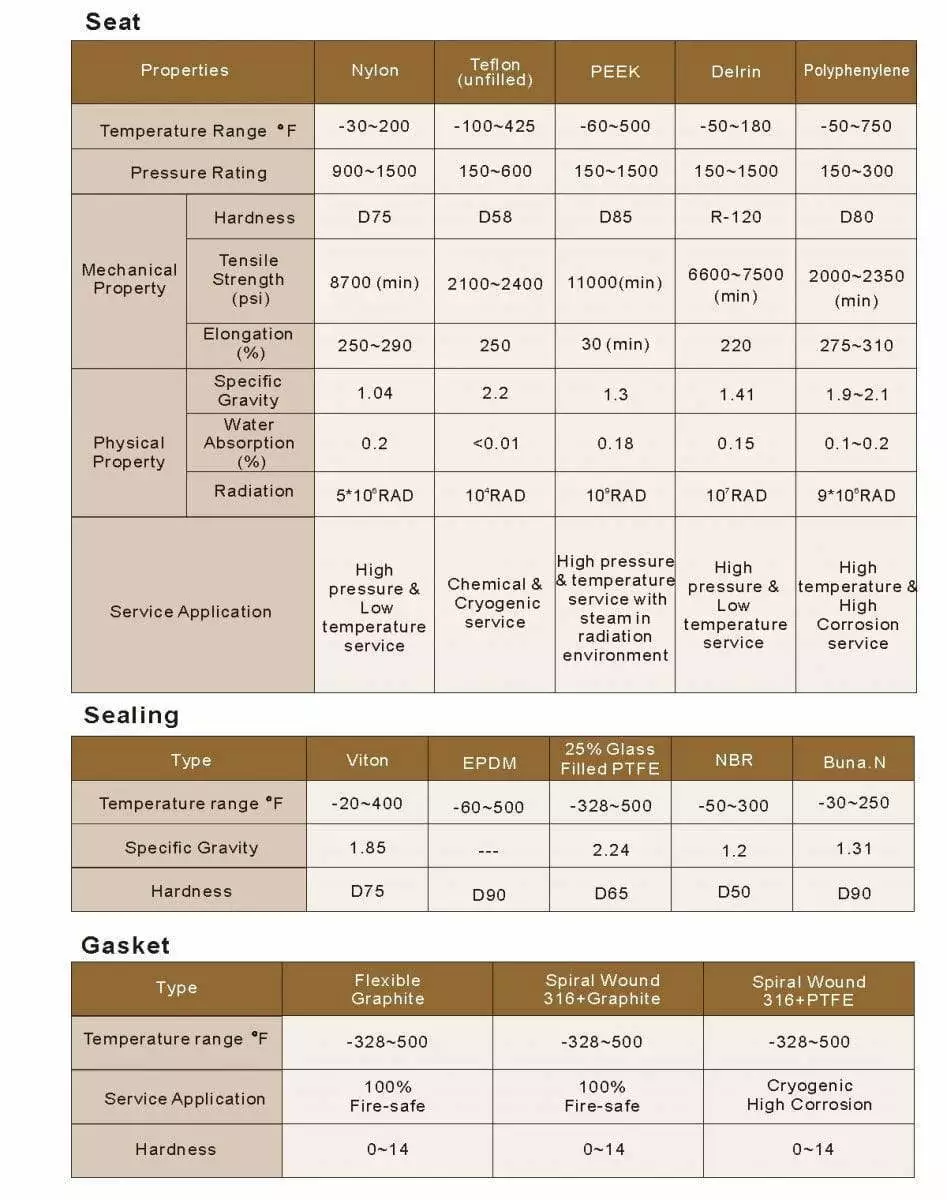

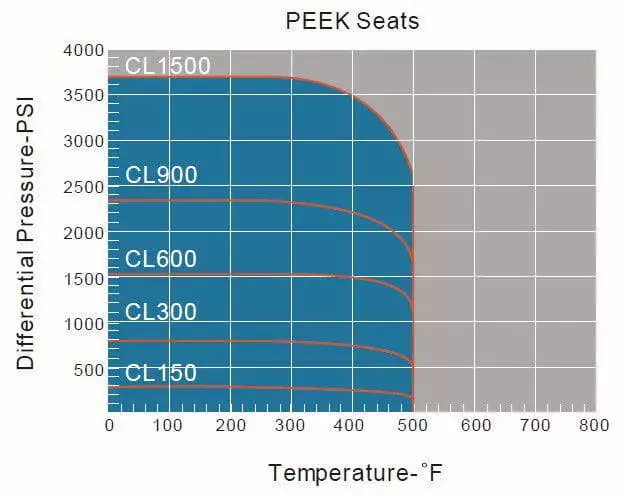

PEEK (Polyether Ether Ketone)

PEEK has good chemical resistance, and also high-temperature tolerance. Ideal for high-pressure applications. Other thermoplastics should be used for low-pressure applications. Do not use in applications prone to thermal shock, or in Chlorine and Sulfuric Acid applications.

Temperature Range: -50°F to 550°F

Max Pressure at Room Temperature: 6000 psi

Color: Beige

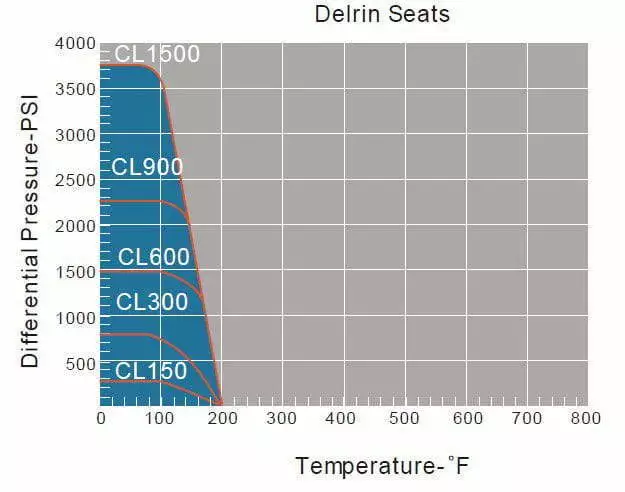

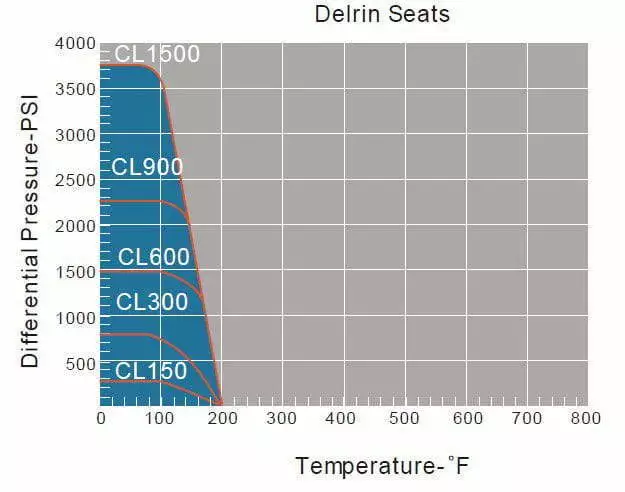

Delrin (Polyoxymethylene)

Delrin has decent chemical resistance and is ideal for high-pressure applications. Do not use in Oxygen service.

Temperature Range: -40°F to 180°F

Max Pressure at Room Temperature: 6000 psi

Color: White

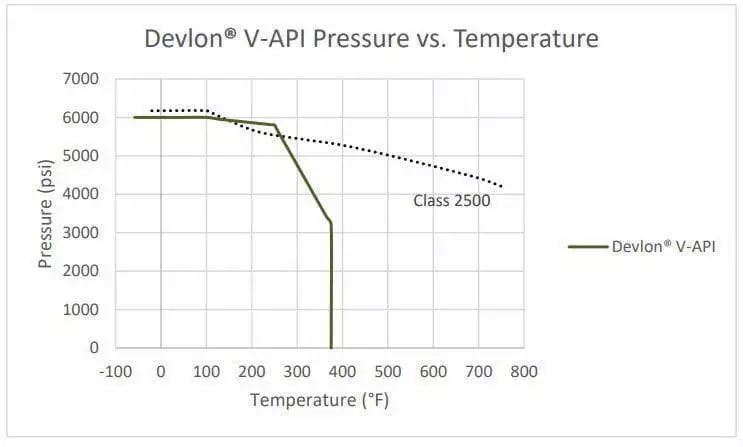

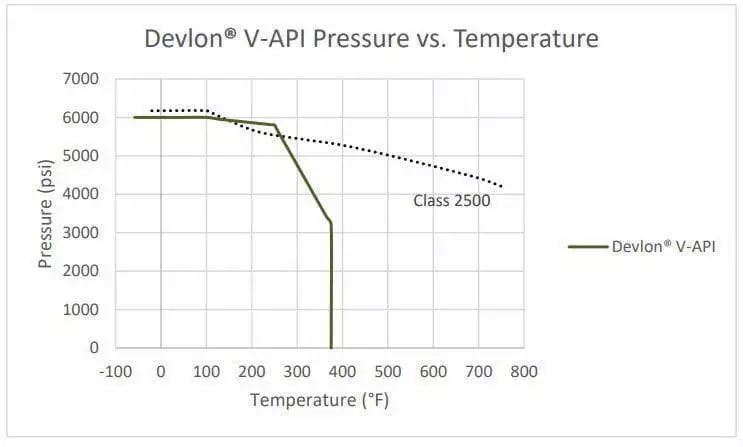

DEVLON V

Devlon V-API is a polyamide that has mechanical properties that are comparable to PEEK but does not share its high-temperature characteristics. It is able to withstand high pressures. Avoid using alcohol, amines, and acids.

Temperature Range: -58°F to 375°F

Max Pressure at Room Temperature: 6000 psi

Color: Yellow

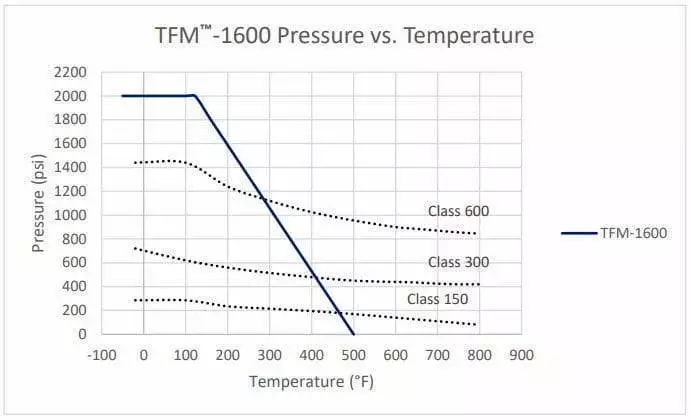

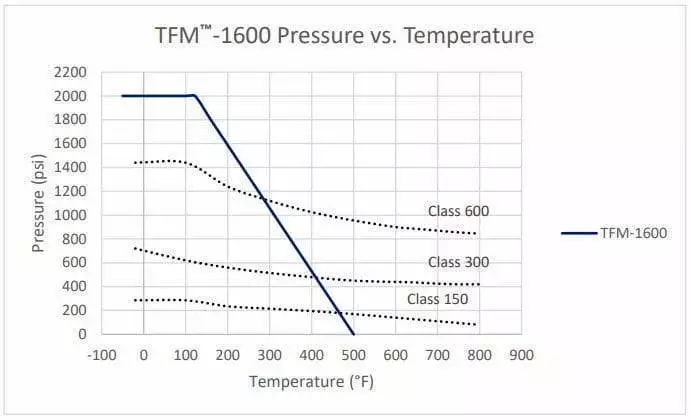

TFM 1600

TFM™-1600 is second generation PTFE. TFM™-1600 has a lower coefficient of friction that provides better creep resistance than PTFE. TFM™-1600 is ideal for high-purity applications such as semi-conductor, and also in lower temperature applications.

Temperature Range: -75°F to 500°F

Max Pressure at Room Temperature: 2000 psi

Color: Transparent White

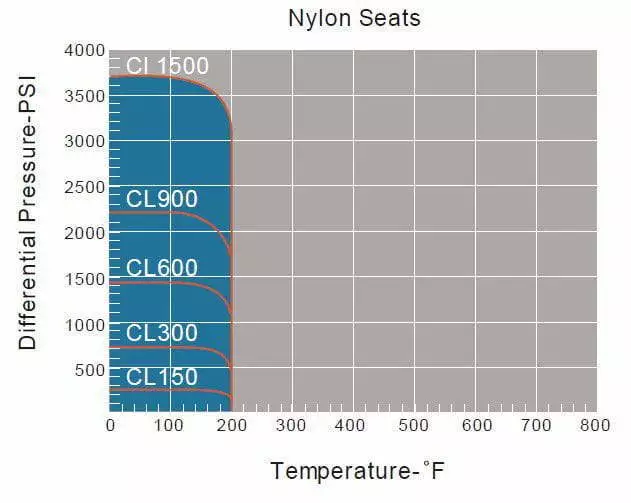

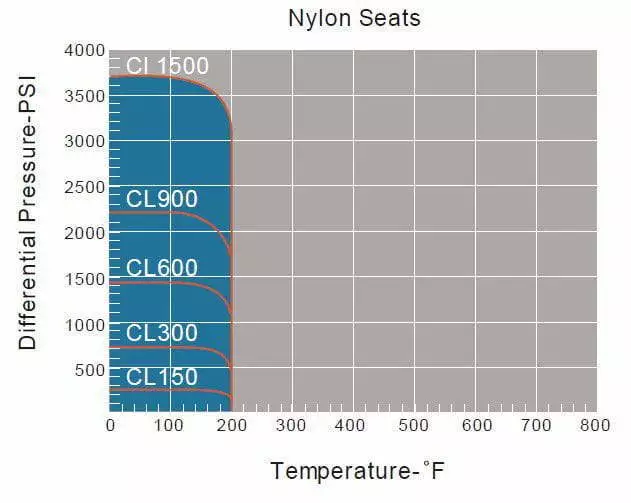

NYLON

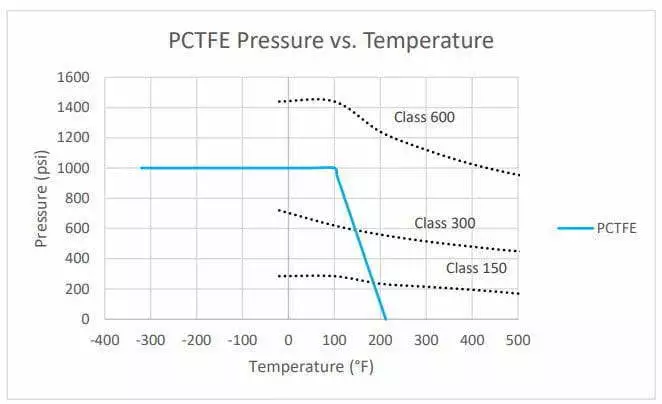

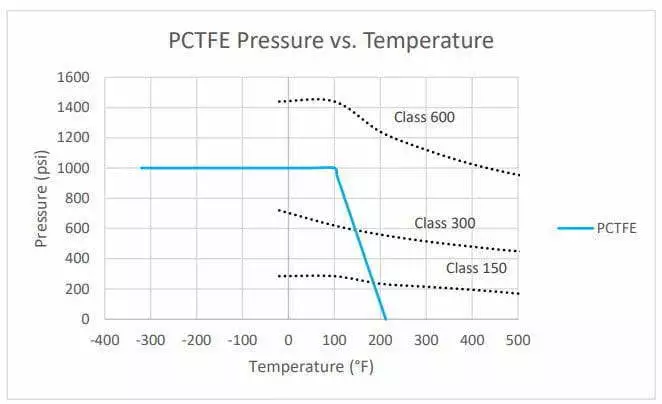

PCTFE (Polychlorotrifluoroethene)

PCTFE is ideal in applications with low and cryogenic temperatures. It offers comparable chemical compatibility to PTFE, with few differences (should not be used for Ethylene Oxide applications, for example).

Temperature Range: -320°F to 212°F

Max Pressure at Room Temperature: 1000 psi

Color: Transparent White

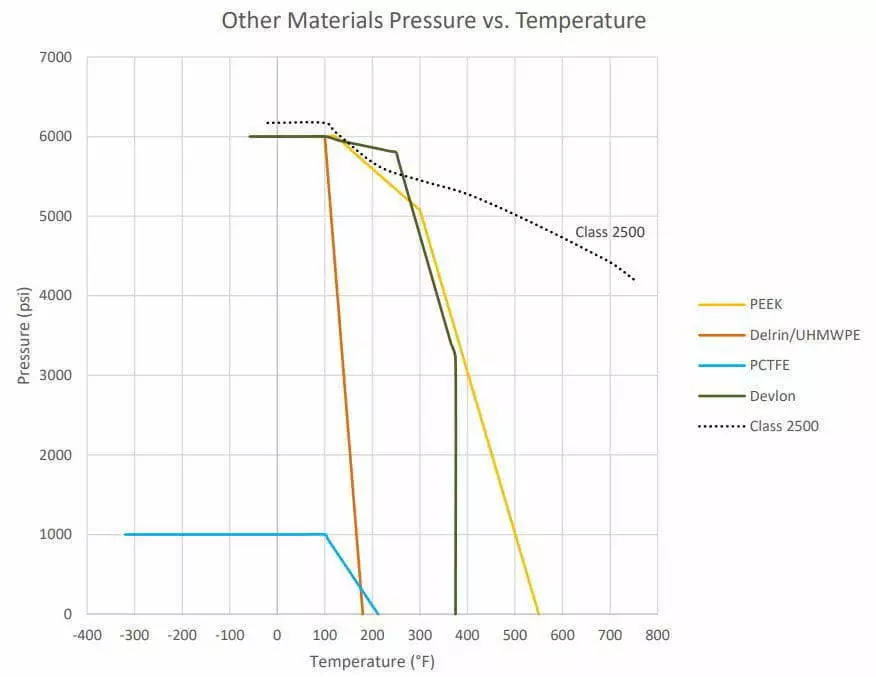

Below are pressure-temperature ratings for more materials:

PTFE (100% Polytetrafluoroethylene)

Commonly referred to as DuPont’s Teflon®, PTFE is a thermoplastic fluoropolymer that consists of Carbon and Fluorine. This structure allows PTFE to be non-reactive to many chemicals and applied to severe chemical environments. PTFE is ideal for low-cycle life applications. Do not use in molten alkali metal and molten Fluorine applications.

Temperature Range: -50°F to 400°F

Max Pressure at Room Temperature: 1000 psi

Color: White

RPTFE (Glass Filled)

RPTFE has improved wear and abrasion resistance over PTFE while maintaining its chemical compatibility. Its versatile temperature characteristics allow RTFE to be used in saturated steam applications. This seat should not be used in caustic (sodium hydroxide, potassium hydroxide, etc.) service.

Temperature Range: -50°F to 450°F

Max Pressure at Room Temperature: 2000 psi

Color: Off-White

RPTFE (Carbon Filled)

Carbon-filled RPTFE is used for low-pressure steam applications, and abrasive, and slurry services. It offers comparable chemical resistance to PTFE.

Temperature Range: -50°F to 480°F

Max Pressure at Room Temperature: 2000 psi

Color: Black

PEEK (Polyether Ether Ketone)

PEEK has good chemical resistance, and also high-temperature tolerance. Ideal for high-pressure applications. Other thermoplastics should be used for low-pressure applications. Do not use in applications prone to thermal shock, or in Chlorine and Sulfuric Acid applications.

Temperature Range: -50°F to 550°F

Max Pressure at Room Temperature: 6000 psi

Color: Beige

Delrin (Polyoxymethylene)

Delrin has decent chemical resistance and is ideal for high-pressure applications. Do not use in Oxygen service.

Temperature Range: -40°F to 180°F

Max Pressure at Room Temperature: 6000 psi

Color: White

DEVLON V

Devlon V-API is a polyamide that has mechanical properties that are comparable to PEEK but does not share its high-temperature characteristics. It is able to withstand high pressures. Avoid using alcohol, amines, and acids.

Temperature Range: -58°F to 375°F

Max Pressure at Room Temperature: 6000 psi

Color: Yellow

TFM 1600

TFM™-1600 is second generation PTFE. TFM™-1600 has a lower coefficient of friction that provides better creep resistance than PTFE. TFM™-1600 is ideal for high-purity applications such as semi-conductor, and also in lower temperature applications.

Temperature Range: -75°F to 500°F

Max Pressure at Room Temperature: 2000 psi

Color: Transparent White

NYLON

PCTFE (Polychlorotrifluoroethene)

PCTFE is ideal in applications with low and cryogenic temperatures. It offers comparable chemical compatibility to PTFE, with few differences (should not be used for Ethylene Oxide applications, for example).

Temperature Range: -320°F to 212°F

Max Pressure at Room Temperature: 1000 psi

Color: Transparent White

Below are pressure-temperature ratings for more materials:

Next: High Performance Butterfly Valve

Previous: What is difference between DBB and DIB ball valves?

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China