Norsok Valve Design Requirements

Nov 27, 2024

On this page

Bosseal factory is a professional valve manufacturer for offshore projects and in compliance with most critical industrial standards like Norsok.

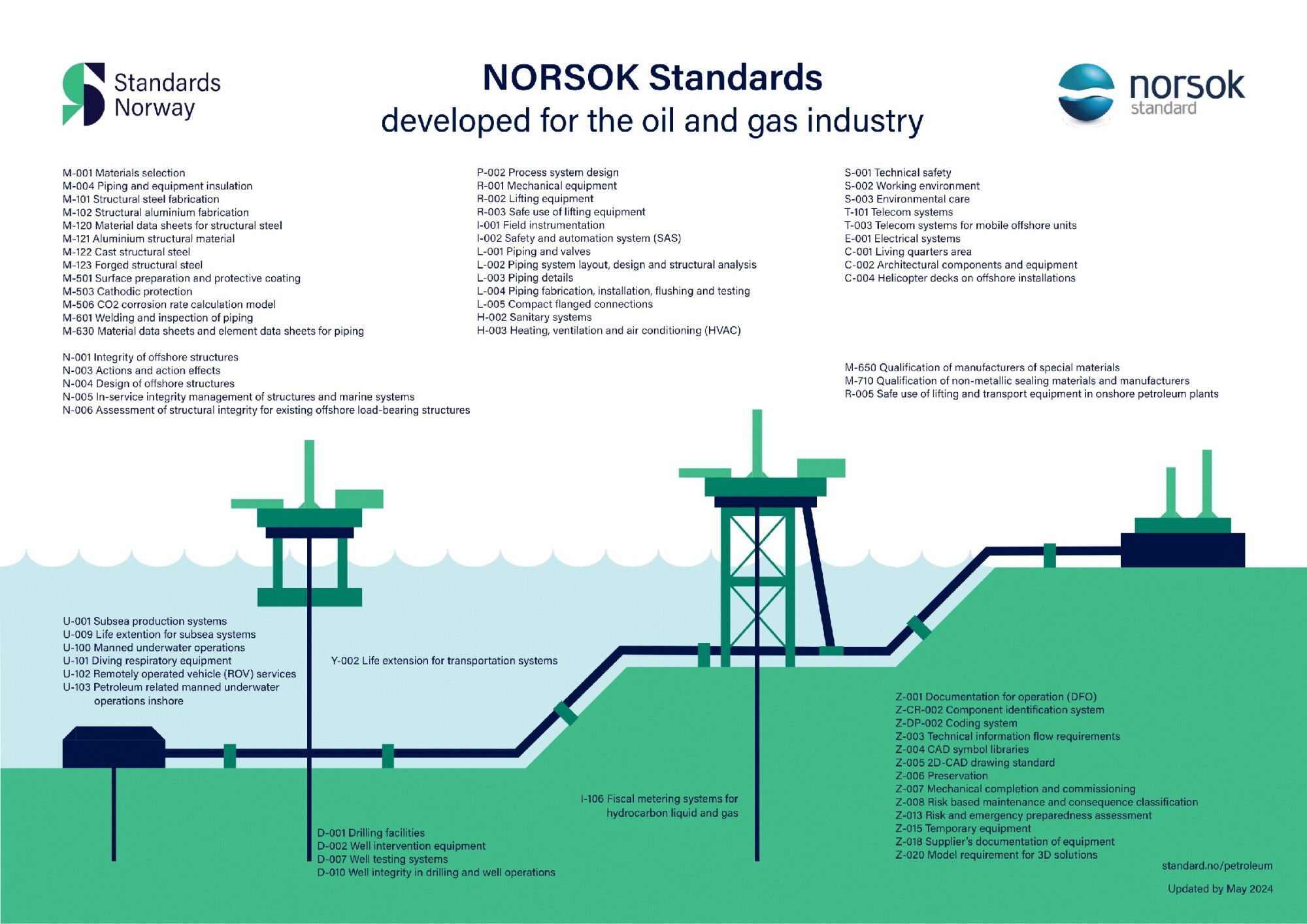

There are forty years of petroleum experience from the Norwegian Continental Shelf behind the NORSOK standards. The acronym NORSOK originally stood for "Norwegian Shelf's Competitive Position" and was introduced in 1994 to reduce costs and improve competitiveness on the Norwegian Continental Shelf.

The NORSOK standards are developed by the Norwegian petroleum industry to ensure adequate safety, value addition, and cost-effectiveness in petroleum industry developments and operations.

These standards are typically based on recognized international standards, with additional provisions deemed necessary to address the specific needs of the Norwegian petroleum industry.

NORSOK L-001: Piping and Valves

NORSOK M-501: Surface preparation and protective coating

NORSOK M-601: Welding and inspection of piping

NORSOK M-630: Material data sheets and element data sheets for piping

NORSOK M-650: Qualification of manufacturers of special materials

These standards were originally developed for the Norwegian market but have since been adopted by many other countries. Major companies like Statoil, ExxonMobil, BP, and Shell now use them due to their high safety standards for oil and gas projects.

The standards cover everything from basic design and raw materials to valve design, welding, and painting. Among them, the most commonly used standards are NORSOK M-630 and NORSOK M-650.

NORSOK M-630 is a set of Material Data Sheets (MDS) that outline the requirements, such as chemistry, mechanical properties, that materials must meet to be qualified. NORSOK M-630 includes specifications for forging and bar materials, including Duplex A182 F51 UNS S31803, Super Duplex A182 F53 UNS S32750, A182 F55 S32670, Nickel alloy Inconel UNS N06625, 254 SMO UNS S31254, and Titanium B381 Grade F2 B348 Grade 2.

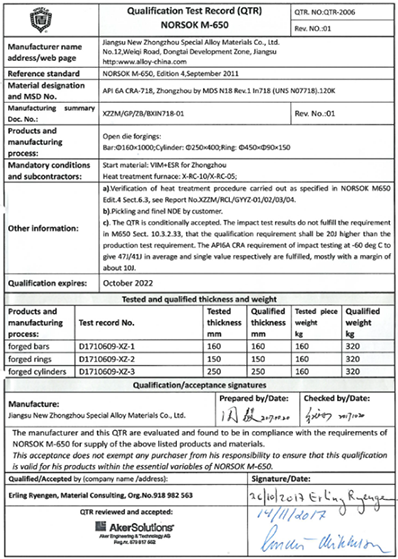

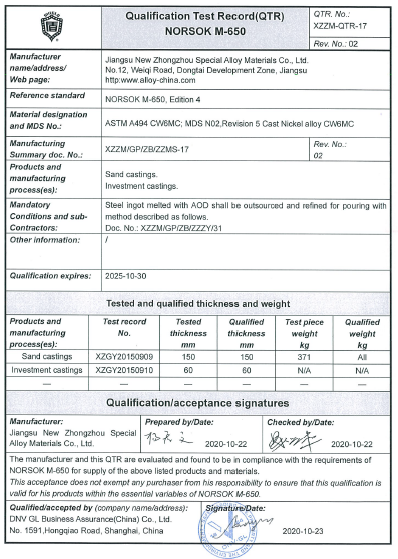

NORSOK M-650 is the procedure for qualifying manufacturers of special materials used in offshore projects, such as duplex, super duplex, nickel alloys, and titanium. There are two types of final qualification: one is official approval from Aker Solutions, and the other is approval from a third-party organization, such as DNV, to qualify according to NORSOK standards.

Bosseal Valves is a professional valve manufacturer specializing in offshore projects with high-quality requirements, including offshore platforms and FPSOs, using materials such as duplex, alloy, and titanium. For any technical or commercial support, please contact our team at [email protected].

Next: Marine Painting for Valves (C5-M)

Previous: Typical Stainless Steel Materials for Ball Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China