Mitigating Cavitation Damage in Industrial Valves and Piping Systems

Jun 17, 2024

On this page

Cavitation poses a significant threat to the safety and reliability of equipment in industrial operations. It not only damages industrial valves themselves but also has the potential to cause severe harm to entire pipeline systems and associated equipment. The high levels of noise and frequent vibrations often lead to rapid deterioration of valve internals and pipelines, accelerating the aging of components and corrosion of equipment. In this article, we will explore the effects of cavitation on industrial valves and pipeline systems, address these challenges, and propose recommendations to ensure long-term operational stability and production efficiency.

The core issue of cavitation lies in the vibrational energy and high noise levels that cause physical damage to pipelines, such as cracks and corrosion. Additionally, cavitation induces erosion in dynamic components of equipment, hastening surface wear processes that affect the normal functioning of instruments like pressure gauges, transmitters, thermocouple sheaths, and flow meters.

Specifically, cavitation affects not only the internals of valves and pipelines but also impacts the performance of downstream equipment. High-amplitude vibrations can lead to metal part cracking and corrosion, potentially contaminating pipeline media with released metal particles or corrosive materials, posing serious challenges for handling sanitary-grade and high-purity pipeline media.

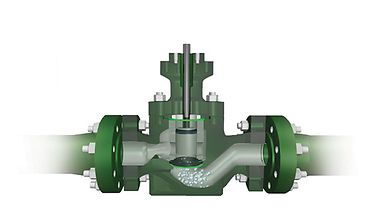

To effectively address the challenges posed by cavitation, engineers have developed a range of specially designed valves primarily focusing on two aspects: flow division and staged pressure drop.

1. Flow Division Design

By dividing high flows into several smaller streams, the occurrence of cavitation issues can be minimized. This design employs multiple parallel small openings in the valve flow path, effectively controlling the size and number of cavities, thereby reducing noise and damage. For instance, designs like V-ball valves maintain smooth fluid flow at higher recovery rates, reducing the likelihood of cavitation bubble formation.

2. Staged Pressure Drop

Traditional valves typically achieve the entire pressure drop in a single step, whereas staged pressure drop designs divide the pressure drop into two or more serial stages. This method prevents high vibrations and noise generated by choking effects in a single step, effectively eliminating cavitation. By gradually lowering pressure, fluid velocity is controlled to reduce cavitation bubble formation, thereby mitigating damage to valves and pipelines.

3. Integrated Applications

Combining flow division and staged pressure drop designs in the same valve significantly enhances cavitation resistance. Additionally, thoughtful valve positioning and temperature control effectively reduce cavitation risks, especially in cases of low liquid temperatures or high pressures. For example, using specifically designed valves on the low-temperature side of heat exchangers effectively reduces liquid vapor pressure, further minimizing cavitation risks.

In conclusion, through innovative valve designs and process control measures, engineers can effectively eliminate or reduce the serious damage caused by cavitation to industrial equipment and pipeline systems. These methods not only improve equipment lifespan and reliability but also reduce maintenance costs and the risk of production interruptions, thereby playing a crucial role in the sustainable development of modern industries.

Next: Choosing the Right Gate Valve: Types, Advantages and Considerations

Previous: Forged Steel Gate Valves in High-Temp, High-Pressure Applications

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China