Knife and Wedge Gate Valves: Key Differences and Applications

Sep 02, 2024

On this page

In industrial process control, selecting the appropriate valve is crucial for ensuring the efficient operation of the system. Knife gate valves and wedge gate valves are two common types of gate valves, each with distinct features and important roles in various applications. Knife gate valves, with their unique cutting function and wear resistance, are widely used for handling media containing fibers or slurries. On the other hand, wedge gate valves, known for their superior sealing performance and high adaptability, are particularly suited for high-pressure and high-temperature environments. This article will provide a detailed comparison of the two gate valves, offering a comprehensive analysis to support valve selection and system design.

The structure and design of a valve are key factors determining its performance and suitability. Although both knife gate valves and wedge gate valves belong to the gate valve category, they exhibit significant structural differences that directly impact their application effectiveness and performance characteristics. Below is a detailed comparison of the structure and design of these two types of valves to help understand their respective advantages and application scenarios.

The gate of a knife gate valve is blade-shaped, designed to effectively cut through media containing fibers, paper pulp, or slurries. This design not only helps block the fluid flow but also prevents sediment accumulation. The sealing surface of the gate is typically wedge-shaped, with an angle usually set at 5°. Knife gate valves can have either rigid or flexible gates. Rigid gates are a single piece, suitable for standard applications, while flexible gates can slightly deform to correct deviations in sealing surface angles during manufacturing, providing a more precise seal.

The body of a knife gate valve is usually designed without internal chambers, with the gate moving up and down within side guide slots. The bottom flanges press firmly against the seat to ensure stable sealing. The seat often uses an O-ring seal for bidirectional sealing, making it particularly suitable for applications requiring leak prevention.

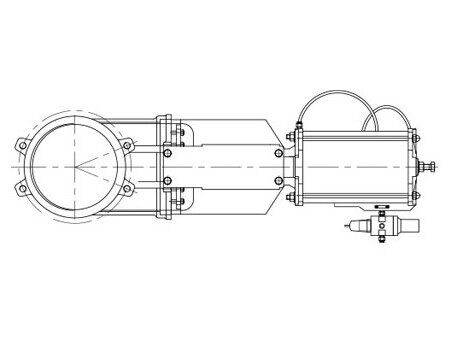

Knife gate valves are typically equipped with pneumatic actuators, comprising an actuator in the upper part and the valve body in the lower part. Pneumatic actuators provide efficient, automated control, allowing the valve to respond quickly to operational commands. The valve body is designed with a full circular passage, which reduces the accumulation of impurities and effectively prevents blockages.

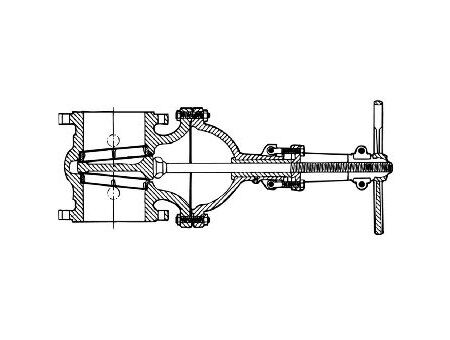

The gate of a wedge gate valve is wedge-shaped, designed to enhance sealing load and ensure effective sealing under high media pressure. The wedge design improves contact on the sealing surface, adapting to pressure changes of different media, thus enhancing sealing performance. Wedge gate valves are particularly notable for their sealing performance when handling high-pressure media.

Wedge gate valves feature guiding mechanisms on the valve body to prevent the gate from rotating during opening or closing, ensuring precise alignment of the sealing surface and reducing friction and wear. The body design usually does not include flow passages, which can restrict fluid flow. Additionally, thermal expansion of the valve stem may lead to overloading of the sealing surface.

Sealing in wedge gate valves relies on the wedging action to create sealing load, and the sealing surface can be prone to solid particles in the flowing media. Rubber-sealed wedge gate valves can effectively seal media containing fine particles.

Understanding the advantages and disadvantages of each valve type is crucial for ensuring their performance in specific applications. Both knife gate valves and wedge gate valves have unique strengths and weaknesses that influence their suitability for different scenarios.

Effective Cutting: The blade-shaped gate design efficiently handles media with fibers and slurries.

Compact Design: Small footprint and easy installation.

Self-Sealing Function: Utilizes media pressure for sealing, simplifying operation.

Wear Resistance: Designed to handle media with solid particles, offering high durability.

Sealing Performance: May be insufficient in extreme high-pressure or high-temperature applications.

Throttling Capability: Not suitable for throttling control, primarily used for on-off functions.

Superior Sealing: Provides high sealing performance, suitable for high-pressure and high-temperature environments.

Durability: Guiding mechanisms reduce wear, extending service life.

Adaptability: Capable of handling various media, including those with solid particles.

Flow Restriction: Lack of flow passages in the body may affect fluid flow.

Thermal Expansion: Valve stem thermal expansion may lead to sealing surface overload.

Complex Drive: Electric actuators are complex and require higher closing torque.

Performance and application are core factors in evaluating valve types, with different structural designs affecting operational performance and environmental suitability. Knife gate valves and wedge gate valves each offer distinct advantages in performance and application scenarios.

Knife gate valves offer excellent cutting capability, effectively handling media containing fibers, paper pulp, wood pulp, or slurries. Their design prevents impurity buildup, providing good opening and closing performance. The self-sealing function simplifies operation by utilizing media pressure.

Knife gate valves are widely used in wastewater treatment, paper and pulp industries, chemical processing, and other fields requiring the handling of fiber or slurry-containing media. Due to their wear resistance and cost-effectiveness, knife gate valves play a crucial role in industrial processes, particularly in applications requiring rapid switching and high durability.

Wedge gate valves provide strong sealing performance, suitable for high media pressure and temperature applications. Their sealing capabilities are excellent under high pressure but may be less effective under low media pressure compared to other gate valves. The design is ideal for applications demanding high sealing reliability.

Wedge gate valves are extensively used in petrochemical, power generation, oil refining, municipal water engineering, and wastewater treatment industries. They are suitable for high-pressure and high-temperature environments, especially in pipelines for oil products and steam.

Knife gate valves and wedge gate valves each offer unique advantages and applications. Knife gate valves, with their efficient cutting ability and self-sealing function, are ideal for handling media containing fibers and slurries, particularly where high durability and cost-effectiveness are required. Wedge gate valves, with superior sealing performance and adaptability, are suitable for high-pressure and high-temperature environments, especially in high-demand applications in industries like petrochemicals and power generation. Selecting the appropriate valve type should be based on specific application requirements, media characteristics, and operating conditions.

Next: Design and Advantages of Pneumatic Three-Way Ball Valves

Previous: Understand Differences Between Pin and Pinless Butterfly Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China