Key Features of Metal Seated Ball Valves

Mar 07, 2024

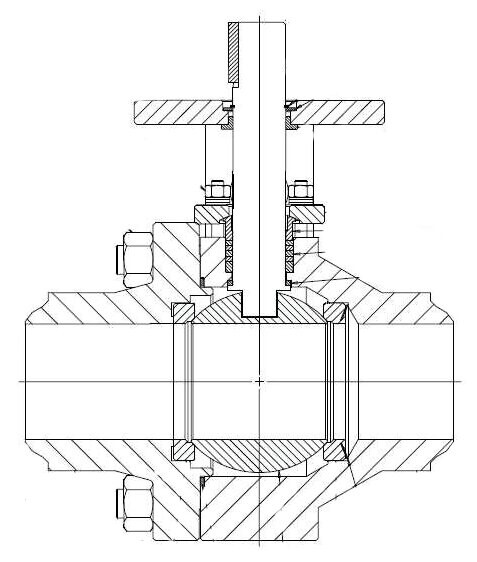

In today's industrial field, metal seated ball valves play a crucial role as key components for fluid control, ensuring production safety and process stability. They boast a multitude of design and structural features aimed at guaranteeing efficient and reliable operation under diverse working conditions. Let's delve into these characteristics to gain a better understanding of the value of this pivotal ball valve.

1. Dual Block and Bleed

Utilizing advanced spring-loaded floating valve seat design, metal seated ball valves ensure bi-directional blocking in fully open or fully closed states and maintain pipeline cleanliness by discharging residual media through bleed valves.

2. Automatic Pressure Relief

During abnormal temperature increases within the valve body cavity, metal seated ball valves achieve automatic pressure relief through seat design, eliminating the need for additional safety valves and effectively mitigating safety hazards arising from abnormal pressure.

3. Fire-Proof Structure

To address emergencies such as fires, metal seated ball valves strictly adhere to API 607 and API 6FA specifications during design and manufacturing, ensuring excellent fire safety performance to effectively safeguard production facilities and personnel.

4. Emergency Seal Greasing

In addition to prioritizing the valve's inherent sealing performance, metal seated ball valves are equipped with emergency seal greasing systems. In the event of seat seal failure due to foreign objects or fire, the greasing valve swiftly connects to a grease gun, injecting sealing grease into the seat seal area to promptly alleviate leakage, ensuring the safe operation of production equipment and pipelines.

5. Reliable Stem Seal and Low Operating Torque

The sealing performance of the stem is critical for the proper operation of ball valves. Metal seated ball valves feature a dual-seal design, incorporating standard sealing rings and "O"-ring seals on the packing gland, effectively preventing media leakage. Additionally, the inclusion of graphite packing and seal greasing technology minimizes stem leakage to the lowest levels in the event of a fire, ensuring the safe and stable operation of production systems.

6. Full Bore or Reduced Bore

Tailored to specific requirements, metal seated ball valves can be provided in full bore or reduced bore configurations to accommodate different pipeline sizes. The full bore design ensures unimpeded flow of pipeline fluids, facilitating cleaning and maintenance.

7. Extendable Stem

To adapt to various installation scenarios, the stem of metal seated ball valves can be lengthened as per customer requirements, particularly suitable for situations requiring buried pipeline installation. The extended stem size offers flexibility to meet diverse engineering needs.

8. Flexible Operation

The operational performance of valves directly impacts the efficiency of production systems. Metal seated ball valves feature valve seats and stem bearings with excellent self-lubricating properties, significantly reducing friction during operation. Even without sealing grease, they ensure long-term flexible operation.

9. Diverse Driving Methods

Metal seated ball valves offer flexible and diverse driving methods, including manual, pneumatic, electric, pneumatic-hydraulic linkage, and hydraulic operations. This facilitates easy automation control according to specific needs, enhancing production efficiency and safety.

Utilizing advanced spring-loaded floating valve seat design, metal seated ball valves ensure bi-directional blocking in fully open or fully closed states and maintain pipeline cleanliness by discharging residual media through bleed valves.

2. Automatic Pressure Relief

During abnormal temperature increases within the valve body cavity, metal seated ball valves achieve automatic pressure relief through seat design, eliminating the need for additional safety valves and effectively mitigating safety hazards arising from abnormal pressure.

3. Fire-Proof Structure

To address emergencies such as fires, metal seated ball valves strictly adhere to API 607 and API 6FA specifications during design and manufacturing, ensuring excellent fire safety performance to effectively safeguard production facilities and personnel.

4. Emergency Seal Greasing

In addition to prioritizing the valve's inherent sealing performance, metal seated ball valves are equipped with emergency seal greasing systems. In the event of seat seal failure due to foreign objects or fire, the greasing valve swiftly connects to a grease gun, injecting sealing grease into the seat seal area to promptly alleviate leakage, ensuring the safe operation of production equipment and pipelines.

5. Reliable Stem Seal and Low Operating Torque

The sealing performance of the stem is critical for the proper operation of ball valves. Metal seated ball valves feature a dual-seal design, incorporating standard sealing rings and "O"-ring seals on the packing gland, effectively preventing media leakage. Additionally, the inclusion of graphite packing and seal greasing technology minimizes stem leakage to the lowest levels in the event of a fire, ensuring the safe and stable operation of production systems.

6. Full Bore or Reduced Bore

Tailored to specific requirements, metal seated ball valves can be provided in full bore or reduced bore configurations to accommodate different pipeline sizes. The full bore design ensures unimpeded flow of pipeline fluids, facilitating cleaning and maintenance.

7. Extendable Stem

To adapt to various installation scenarios, the stem of metal seated ball valves can be lengthened as per customer requirements, particularly suitable for situations requiring buried pipeline installation. The extended stem size offers flexibility to meet diverse engineering needs.

8. Flexible Operation

The operational performance of valves directly impacts the efficiency of production systems. Metal seated ball valves feature valve seats and stem bearings with excellent self-lubricating properties, significantly reducing friction during operation. Even without sealing grease, they ensure long-term flexible operation.

9. Diverse Driving Methods

Metal seated ball valves offer flexible and diverse driving methods, including manual, pneumatic, electric, pneumatic-hydraulic linkage, and hydraulic operations. This facilitates easy automation control according to specific needs, enhancing production efficiency and safety.

In summary, metal seated ball valves are essential components in industrial production due to their meticulous structure, comprehensive functionality, and flexible operation. Their innovative design and rich features enhance fluid control, ensuring reliable technical support for safe and efficient operations. With advancing industrial technology, these valves are poised to maintain their significant role, contributing to the stable, safe, and sustainable development of industrial processes.

Next: Common Faults and Precautions in Cryogenic Valve Operation

Previous: Fully Welded Ball Valve: Characteristics and Applications

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China