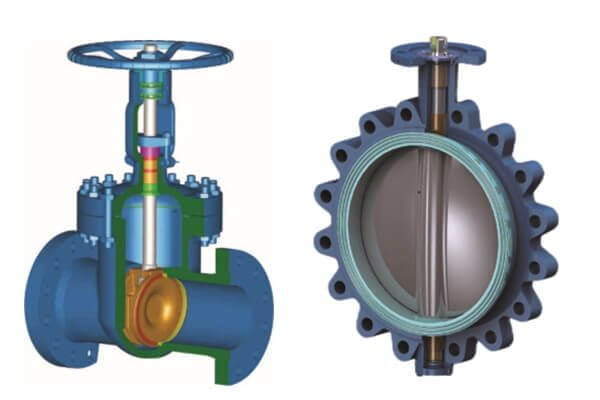

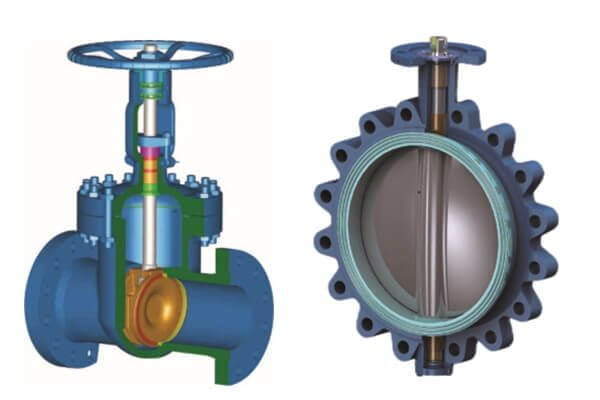

How to Select between Gate Valves and Butterfly Valves

Apr 26, 2023

Gate valves and butterfly valves play the role of shutoff and regulating flow rate in pipeline use. Of course, there are methods in the selection process of a butterfly valve and gate valve, how to choose: gate valve and butterfly valve in the water supply network in order to reduce the depth of soil, generally large diameter pipe with butterfly valve, the impact on the depth of soil is not big, strive to choose the gate valve, but the price of the same specification of a gate valve is higher than the price of a butterfly valve. The dividing line of caliber should be considered everywhere according to the specific situation. In the past ten years, the failure of the butterfly valve is higher than that of the gate valve, so it is worth paying attention to expanding the scope of use of the gate valve if conditions permit.

What is the difference between the use of a butterfly valve and a gate valve?

According to the role and use of the gate valve and butterfly valve, the flow resistance of the gate valve is small and the sealing performance is good. Because the flow direction of the gate valve plate and the medium is vertical Angle, if the gate valve switch in the valve plate is not in place, the erosion of the medium on the valve plate makes the valve plate vibrate, which is easy to result in the gate valve seal damage.

A butterfly valve, also called a flip valve, is a simple structure of the regulator, that can be used for low-pressure pipeline medium switch control butterfly valve refers to the closing part (disc or disc) for the disc, revolving around the valve shaft to achieve the opening and closing of a valve, Valves can be used to control air, water, steam, all kinds of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The pipeline mainly plays the role of cutting and throttling. Butterfly valve opening and closing parts is a disc-shaped butterfly plate, in the valve body around its own axis rotation, so as to achieve the purpose of opening and closing or adjustment. The disc is driven by the valve stem. If it is turned 90°, it can be opened and closed once. Changing the deflection Angle of the butterfly plate can control the flow of the medium.

Working condition and medium: butterfly valve is suitable for producing furnace, gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting and power generation environmental protection, building water supply and drainage engineering systems in the transmission of various corrosive, non-corrosive fluid medium pipeline, used to adjust and cut off the flow of media.

The gate valve is an opening and closing part of the gate, the direction of the motion of the gate is perpendicular to the direction of the fluid, the gate valve can only be fully opened and fully closed, the door parameters vary, usually 5° medium temperature is not high 2°52 '. To improve its technology and make up for the deviation of the sealing surface Angle in the process of processing this kind of ram is called elastic ram. When the gate valve is closed, the sealing surface can only rely on the medium pressure to seal, that is, only rely on the medium pressure to press the sealing surface of the gate to the seat on the other side to ensure the sealing surface, which is self-sealing. Most gate valves are forced to seal, that is, when the valve is closed, the external force is forced to press the gate against the seat to ensure the sealing surface.

Mode of motion: The gate valve with the stem for linear motion is also called the open rod gate valve. Usually, there is a ladder thread on the lifting rod through the nut at the top of the valve and the guide groove on the valve body to change the rotating motion into a straight motion that is to change the operating torque into the operating thrust. When the valve is opened, the path of the fluid is completely clear when the ram elevation is equal to 1:1 of the valve diameter, but this position cannot be monitored during operation. In actual use, the vertex of the stem is used as a symbol, that is, the position that cannot be opened is used as its full open position. Locking to account for temperature changes usually occurs at the top of the opening and then rewinding 1/2-1 turn to the fully open valve position. Therefore, the fully open position of the valve is determined by the position of the ram (stroke >). Some gate valve stem nut is arranged on the gate plate, and the hand wheel drives the stem to rotate and make the gate plate lift. This kind of valve is called a rotating rod gate valve or dark rod gate valve.

Application of the butterfly valve and application conditions: because of the movement of the butterfly valve plate with wipe ability, most butterfly valves can be used with suspended solid particles of the medium, according to the strength of the seal can also be used for powder and granular media. The structure length and overall height of the butterfly valve are small, open and close fast, in full open with small fluid resistance, when opened to about 15° to 70° between and sensitive flow control, the butterfly valve structure principle is most suitable for the production of large diameter valves.

Under the following working conditions, a butterfly valve is recommended:

1, the requirements of throttling, regulating and controlling flow;

2. Mud medium and medium containing solid particles;

3, require the valve structure length to be short occasions;

4, require the opening and closing speed of the occasion;

5, the occasion of small pressure difference.

The butterfly valve can be used in the double-position adjustment, the shrinking channel, low noise, cavitation and gasification phenomenon, a small amount of leakage to the atmosphere, and the abrasive medium.

When the butterfly valve is used under special working conditions, such as throttle regulation or strict sealing or serious wear, low temperature (deep cooling) and other working conditions, it is necessary to use a special design of three eccentric or double eccentric butterfly valve with a metal seal and adjustment device. Signal butterfly valve by worm gear drive shaft and butterfly plate rotation to achieve opening and closing and control flow. Rotate the worm gear to make the butterfly plate open and close and adjust the flow. The hand wheel rotates clockwise to close the valve.

Use device: Connect the cable core wire to the corresponding terminal according to the electrical control requirements, seal the cable inlet and fix the cable to prevent damage to the cable wiring when the external force is pulling. When the valve is in the "fully closed" position clockwise rotation of the following closing CAM or counterclockwise rotation of the above open CAM, the butterfly valve in the pipeline clamping pays attention to whether the relay is uniform and reliable. After the butterfly valve is installed, the valve plate must be in the open position for the pipeline strength test. After installation of the butterfly valve, the main items to be checked are as follows: butterfly valve seat and O-ring are damaged. Sealing performance of valve plate sealing surface. Butterfly valve repair and assembly, open and close rotation shall not be blocked phenomenon. After the butterfly valve repair and assembly, the sealing performance test should be carried out according to the requirements.

Common failures of gate valves and Preventive Measures:

Gate valves are the main components of oil (gas) wellhead devices. Common failures of several kinds of gate valves in use are as follows:

1, gate valve and gate valve connection leakage: first of all, check whether the gate valve and gate valve connection bolt is tightened, if not tightened, its inner gasket ring and flange sealing groove surface is not fully combined often leading to leakage. Check bolts and nuts in sequence and tighten all bolts until the sealing ring is tightly compressed. Secondly, we should check the size and accuracy of the gasket ring and flange sealing groove surface. If the sealing contact surface size is wrong or too rough, we should repair or update the gasket ring. Moreover, check whether there is some corrosion, sand hole, sand hole or impurities in the contact surface of the gasket ring and flange sealing groove. If there is such a defect, it should be correct

The corresponding repair welding, repair or cleaning.

2. Valve cover leakage: Valve cover leakage This fault phenomenon is mainly manifested in the leakage of packing seals. First of all, check whether the seal is selected correctly and whether it matches the sealing groove. If there is such a problem, it is necessary to replace the sealing ring or repair the sealing groove. Secondly, check whether the sealing parts appear burring, fracturing, torsion and other phenomena, which should be replaced by sealing parts. Check again whether the sealing surface of each sealing groove is rough or has other defects. If there are defects, eliminate the defects or update the damaged parts. The valve cover or bracket has packing to be sealed by compression. The installation of these packing should be checked. If it is found that the upper and lower packing is installed upside down, it should be removed and re-installed in accordance with the correct method. Moreover, check whether the precision of the contact surface of the seals meets the specified requirements.

3, valve body cavity decent leakage: valve body in the casting process, sometimes there will be sand holes, sand holes and other casting defects in the machining process is difficult to be found, once the pressure-hidden casting defects will be exposed. In this case, it is necessary to repair welding, repair or update.

4, valve seat valve plate leakage: Valve seat valve plate leakage is the most common phenomenon in the installation or maintenance of gate valves. Generally, it can be divided into two categories: one is the sealing surface leakage, and the other is the sealing ring root leakage. First of all, the precision of the sealing surface contact between the valve seat and the valve plate should be checked. The sealing surface should be ground at least. If the surface accuracy is found to be too rough, it should be removed and ground again. Secondly, check whether there are pitting, indentation, sand holes, cracks and other defects on the sealing surface. In this case, the valve plate or valve seat should be replaced. For the valve seat with a pressure spring, the elasticity of the pressure spring should be checked to meet the requirements. If the elasticity is weakened, the pressure spring should be updated. Moreover, check whether the T-shaped connection between the valve plate and the valve stem is too loose, resulting in the inclination of the valve plate in the process of compression. In this case, the valve plate should be removed and adjusted to the best size. The valve body inside the opening, in the installation process, is easy to enter during welding inspection, iron filings, impurities and other foreign bodies, should be cleaned up before installation. Such as forgetting to clean up or

If the cleaning is not thorough, it will cause the valve plate to close less than the expected depth and produce leakage. In this case, the valve body should be removed and cleaned again. The valve seat should be installed with a special installation tool, and the valve seat should be checked to see if it is installed in place. If the thread is not screwed to the desired depth, there will be leakage at the valve seat. In this case, the valve seat should be installed again with a special tool.

5, the handwheel rotation is not flexible:

(1) The main reasons: ① stem bending and twisting. (2) The surface accuracy is not enough. ③ Excessive operation causes thread damage. ④ Lack of lubrication or lubricant failure. ⑤ Valve stem nut tilt. ⑥ With tolerance is not allowed, too tight bite. The valve stem thread is covered with dust and sand, or corroded by rain, dew and frost. ⑧ thread by medium corrosion (refers to the dark rod gate valve or stem nut in the lower part of the gate valve). ⑨ Improper material selection. For example, stem and nut are made of the same material, which makes it easy to bite.

(2) Preventive measures and solutions. (1) Strict control of force, not hard torsion (refers to the handwheel and stem directly connected gate valve). ② Improve the processing quality to meet the standard requirements. ③ Careful operation, do not make strong when closing, and do not open to the top dead point, to the dead point should reverse the handwheel one or two circles, so that the upper side of the thread close so as to avoid the medium to push the valve stem upward impact. Often check the lubrication condition, and maintain the normal lubrication state. ⑤ Straighten or correct the stem nut. ⑥ Revise or update the valve stem nut to make it meet the standard specification. Often clean valve stem nut dust, to prevent rust. Open the gate valve to add a stem protection cover. It is better to use copper for valve stem nuts. Do not use the same material as the valve stem.

Butterfly valve and gate valve use simple summary:

Butterfly valve: small volume is easy to install, easy to realize automatic control due to the small opening stroke, suitable for all kinds of liquids including mud, metal, etc., the main valve plate and the opening handle are connected as one is not easy to fail, but large diameter, large diameter pipeline is not easy to use, belonging to the low-pressure valve close strictly.

Gate valve: compared with the butterfly valve, large volume, slow opening speed and large stroke is not easy to realize automatic control, a small range of use, the main valve plate and opening handle are easy to disengage resulting in valve failure, trial for large diameter installation, according to pressure divided into low, medium and high-pressure valve close strictly.

For any further questions please contact the Bosseal team: [email protected].

What is the difference between the use of a butterfly valve and a gate valve?

According to the role and use of the gate valve and butterfly valve, the flow resistance of the gate valve is small and the sealing performance is good. Because the flow direction of the gate valve plate and the medium is vertical Angle, if the gate valve switch in the valve plate is not in place, the erosion of the medium on the valve plate makes the valve plate vibrate, which is easy to result in the gate valve seal damage.

A butterfly valve, also called a flip valve, is a simple structure of the regulator, that can be used for low-pressure pipeline medium switch control butterfly valve refers to the closing part (disc or disc) for the disc, revolving around the valve shaft to achieve the opening and closing of a valve, Valves can be used to control air, water, steam, all kinds of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The pipeline mainly plays the role of cutting and throttling. Butterfly valve opening and closing parts is a disc-shaped butterfly plate, in the valve body around its own axis rotation, so as to achieve the purpose of opening and closing or adjustment. The disc is driven by the valve stem. If it is turned 90°, it can be opened and closed once. Changing the deflection Angle of the butterfly plate can control the flow of the medium.

Working condition and medium: butterfly valve is suitable for producing furnace, gas, natural gas, liquefied petroleum gas, city gas, hot and cold air, chemical smelting and power generation environmental protection, building water supply and drainage engineering systems in the transmission of various corrosive, non-corrosive fluid medium pipeline, used to adjust and cut off the flow of media.

The gate valve is an opening and closing part of the gate, the direction of the motion of the gate is perpendicular to the direction of the fluid, the gate valve can only be fully opened and fully closed, the door parameters vary, usually 5° medium temperature is not high 2°52 '. To improve its technology and make up for the deviation of the sealing surface Angle in the process of processing this kind of ram is called elastic ram. When the gate valve is closed, the sealing surface can only rely on the medium pressure to seal, that is, only rely on the medium pressure to press the sealing surface of the gate to the seat on the other side to ensure the sealing surface, which is self-sealing. Most gate valves are forced to seal, that is, when the valve is closed, the external force is forced to press the gate against the seat to ensure the sealing surface.

Mode of motion: The gate valve with the stem for linear motion is also called the open rod gate valve. Usually, there is a ladder thread on the lifting rod through the nut at the top of the valve and the guide groove on the valve body to change the rotating motion into a straight motion that is to change the operating torque into the operating thrust. When the valve is opened, the path of the fluid is completely clear when the ram elevation is equal to 1:1 of the valve diameter, but this position cannot be monitored during operation. In actual use, the vertex of the stem is used as a symbol, that is, the position that cannot be opened is used as its full open position. Locking to account for temperature changes usually occurs at the top of the opening and then rewinding 1/2-1 turn to the fully open valve position. Therefore, the fully open position of the valve is determined by the position of the ram (stroke >). Some gate valve stem nut is arranged on the gate plate, and the hand wheel drives the stem to rotate and make the gate plate lift. This kind of valve is called a rotating rod gate valve or dark rod gate valve.

Application of the butterfly valve and application conditions: because of the movement of the butterfly valve plate with wipe ability, most butterfly valves can be used with suspended solid particles of the medium, according to the strength of the seal can also be used for powder and granular media. The structure length and overall height of the butterfly valve are small, open and close fast, in full open with small fluid resistance, when opened to about 15° to 70° between and sensitive flow control, the butterfly valve structure principle is most suitable for the production of large diameter valves.

Under the following working conditions, a butterfly valve is recommended:

1, the requirements of throttling, regulating and controlling flow;

2. Mud medium and medium containing solid particles;

3, require the valve structure length to be short occasions;

4, require the opening and closing speed of the occasion;

5, the occasion of small pressure difference.

The butterfly valve can be used in the double-position adjustment, the shrinking channel, low noise, cavitation and gasification phenomenon, a small amount of leakage to the atmosphere, and the abrasive medium.

When the butterfly valve is used under special working conditions, such as throttle regulation or strict sealing or serious wear, low temperature (deep cooling) and other working conditions, it is necessary to use a special design of three eccentric or double eccentric butterfly valve with a metal seal and adjustment device. Signal butterfly valve by worm gear drive shaft and butterfly plate rotation to achieve opening and closing and control flow. Rotate the worm gear to make the butterfly plate open and close and adjust the flow. The hand wheel rotates clockwise to close the valve.

Use device: Connect the cable core wire to the corresponding terminal according to the electrical control requirements, seal the cable inlet and fix the cable to prevent damage to the cable wiring when the external force is pulling. When the valve is in the "fully closed" position clockwise rotation of the following closing CAM or counterclockwise rotation of the above open CAM, the butterfly valve in the pipeline clamping pays attention to whether the relay is uniform and reliable. After the butterfly valve is installed, the valve plate must be in the open position for the pipeline strength test. After installation of the butterfly valve, the main items to be checked are as follows: butterfly valve seat and O-ring are damaged. Sealing performance of valve plate sealing surface. Butterfly valve repair and assembly, open and close rotation shall not be blocked phenomenon. After the butterfly valve repair and assembly, the sealing performance test should be carried out according to the requirements.

Common failures of gate valves and Preventive Measures:

Gate valves are the main components of oil (gas) wellhead devices. Common failures of several kinds of gate valves in use are as follows:

1, gate valve and gate valve connection leakage: first of all, check whether the gate valve and gate valve connection bolt is tightened, if not tightened, its inner gasket ring and flange sealing groove surface is not fully combined often leading to leakage. Check bolts and nuts in sequence and tighten all bolts until the sealing ring is tightly compressed. Secondly, we should check the size and accuracy of the gasket ring and flange sealing groove surface. If the sealing contact surface size is wrong or too rough, we should repair or update the gasket ring. Moreover, check whether there is some corrosion, sand hole, sand hole or impurities in the contact surface of the gasket ring and flange sealing groove. If there is such a defect, it should be correct

The corresponding repair welding, repair or cleaning.

2. Valve cover leakage: Valve cover leakage This fault phenomenon is mainly manifested in the leakage of packing seals. First of all, check whether the seal is selected correctly and whether it matches the sealing groove. If there is such a problem, it is necessary to replace the sealing ring or repair the sealing groove. Secondly, check whether the sealing parts appear burring, fracturing, torsion and other phenomena, which should be replaced by sealing parts. Check again whether the sealing surface of each sealing groove is rough or has other defects. If there are defects, eliminate the defects or update the damaged parts. The valve cover or bracket has packing to be sealed by compression. The installation of these packing should be checked. If it is found that the upper and lower packing is installed upside down, it should be removed and re-installed in accordance with the correct method. Moreover, check whether the precision of the contact surface of the seals meets the specified requirements.

3, valve body cavity decent leakage: valve body in the casting process, sometimes there will be sand holes, sand holes and other casting defects in the machining process is difficult to be found, once the pressure-hidden casting defects will be exposed. In this case, it is necessary to repair welding, repair or update.

4, valve seat valve plate leakage: Valve seat valve plate leakage is the most common phenomenon in the installation or maintenance of gate valves. Generally, it can be divided into two categories: one is the sealing surface leakage, and the other is the sealing ring root leakage. First of all, the precision of the sealing surface contact between the valve seat and the valve plate should be checked. The sealing surface should be ground at least. If the surface accuracy is found to be too rough, it should be removed and ground again. Secondly, check whether there are pitting, indentation, sand holes, cracks and other defects on the sealing surface. In this case, the valve plate or valve seat should be replaced. For the valve seat with a pressure spring, the elasticity of the pressure spring should be checked to meet the requirements. If the elasticity is weakened, the pressure spring should be updated. Moreover, check whether the T-shaped connection between the valve plate and the valve stem is too loose, resulting in the inclination of the valve plate in the process of compression. In this case, the valve plate should be removed and adjusted to the best size. The valve body inside the opening, in the installation process, is easy to enter during welding inspection, iron filings, impurities and other foreign bodies, should be cleaned up before installation. Such as forgetting to clean up or

If the cleaning is not thorough, it will cause the valve plate to close less than the expected depth and produce leakage. In this case, the valve body should be removed and cleaned again. The valve seat should be installed with a special installation tool, and the valve seat should be checked to see if it is installed in place. If the thread is not screwed to the desired depth, there will be leakage at the valve seat. In this case, the valve seat should be installed again with a special tool.

5, the handwheel rotation is not flexible:

(1) The main reasons: ① stem bending and twisting. (2) The surface accuracy is not enough. ③ Excessive operation causes thread damage. ④ Lack of lubrication or lubricant failure. ⑤ Valve stem nut tilt. ⑥ With tolerance is not allowed, too tight bite. The valve stem thread is covered with dust and sand, or corroded by rain, dew and frost. ⑧ thread by medium corrosion (refers to the dark rod gate valve or stem nut in the lower part of the gate valve). ⑨ Improper material selection. For example, stem and nut are made of the same material, which makes it easy to bite.

(2) Preventive measures and solutions. (1) Strict control of force, not hard torsion (refers to the handwheel and stem directly connected gate valve). ② Improve the processing quality to meet the standard requirements. ③ Careful operation, do not make strong when closing, and do not open to the top dead point, to the dead point should reverse the handwheel one or two circles, so that the upper side of the thread close so as to avoid the medium to push the valve stem upward impact. Often check the lubrication condition, and maintain the normal lubrication state. ⑤ Straighten or correct the stem nut. ⑥ Revise or update the valve stem nut to make it meet the standard specification. Often clean valve stem nut dust, to prevent rust. Open the gate valve to add a stem protection cover. It is better to use copper for valve stem nuts. Do not use the same material as the valve stem.

Butterfly valve and gate valve use simple summary:

Butterfly valve: small volume is easy to install, easy to realize automatic control due to the small opening stroke, suitable for all kinds of liquids including mud, metal, etc., the main valve plate and the opening handle are connected as one is not easy to fail, but large diameter, large diameter pipeline is not easy to use, belonging to the low-pressure valve close strictly.

Gate valve: compared with the butterfly valve, large volume, slow opening speed and large stroke is not easy to realize automatic control, a small range of use, the main valve plate and opening handle are easy to disengage resulting in valve failure, trial for large diameter installation, according to pressure divided into low, medium and high-pressure valve close strictly.

For any further questions please contact the Bosseal team: [email protected].

Next: DN2000 Expansion Joint Start Working for Ho Chi Minh Main Water Supply Line

Previous: High Performance Butterfly Valve

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China