High Performance Butterfly Valve

Feb 28, 2023

A High-Performance Butterfly Valve(HPBV) can handle more critical services other than general water and air at a wider temperature and pressure range. Normally the Double Offset and Triple Offset butterfly valves can be used as High Performance, as they are more suitable for higher pressure, temperature and various fluid.

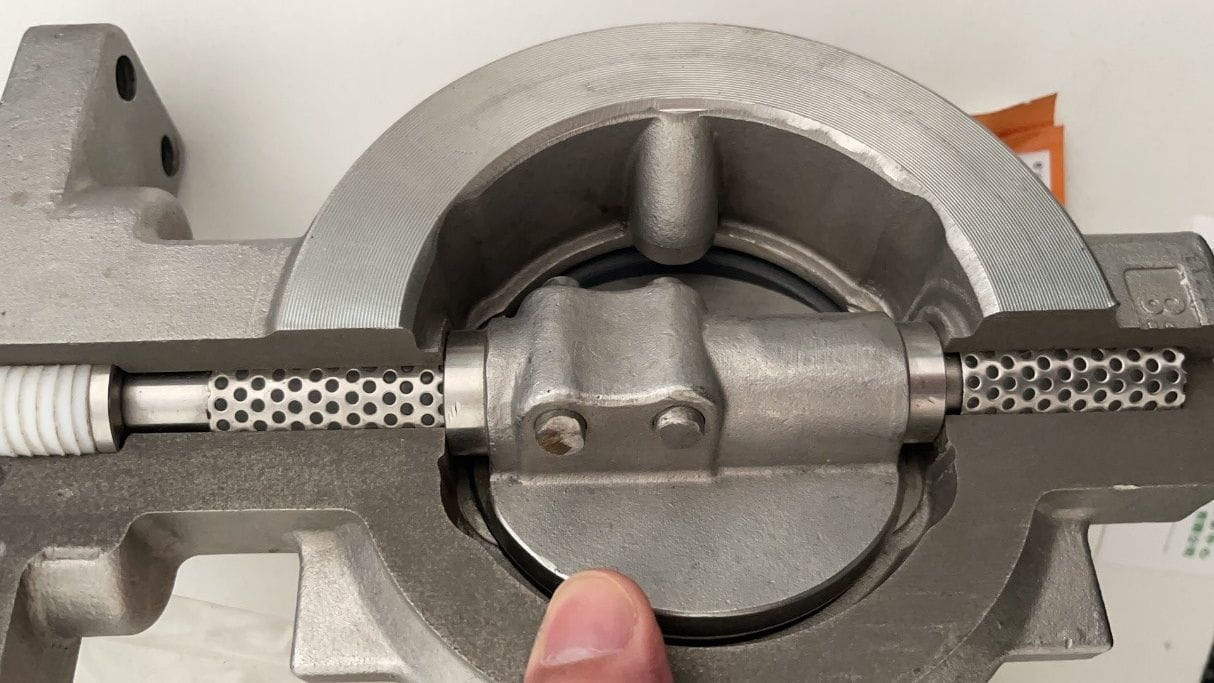

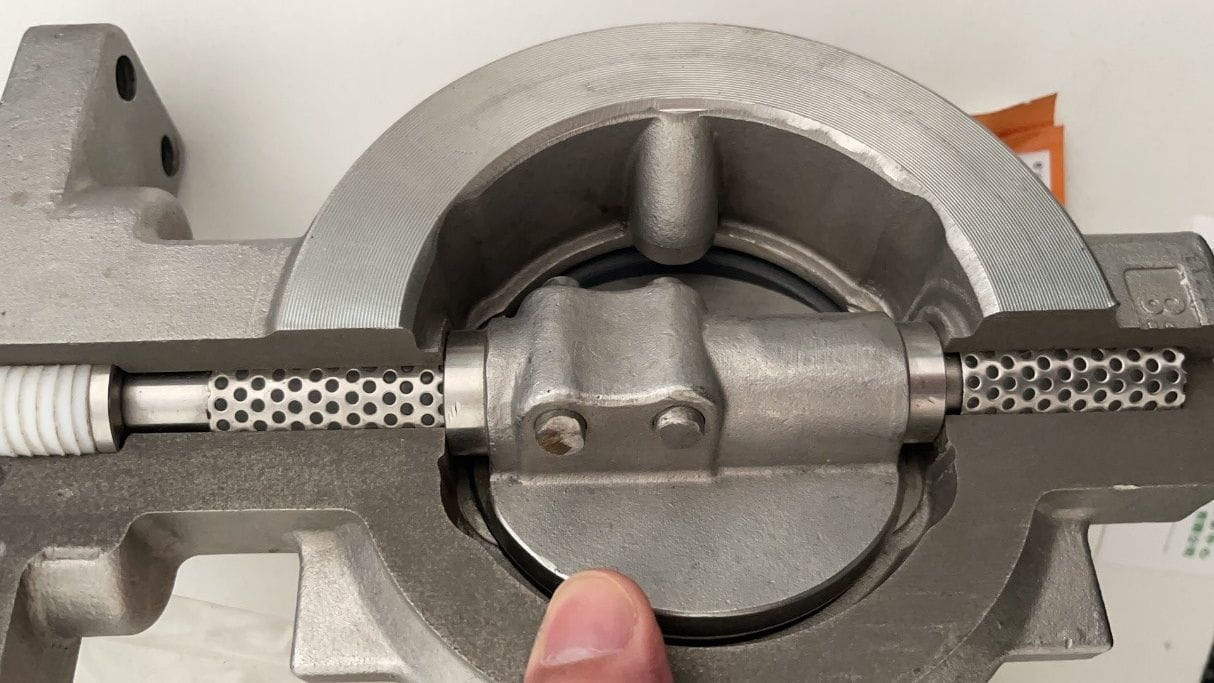

Double Offset Butterfly Valve (Soft Seat)

Triple Offset Butterfly Valve (Metal Seat)

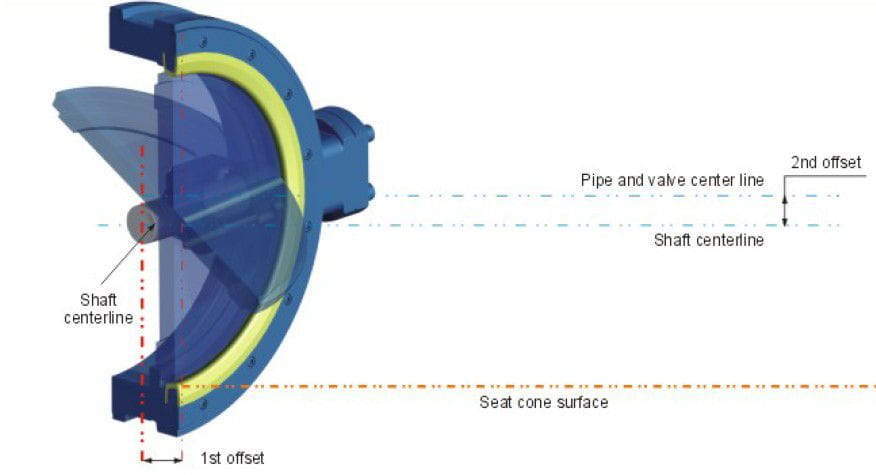

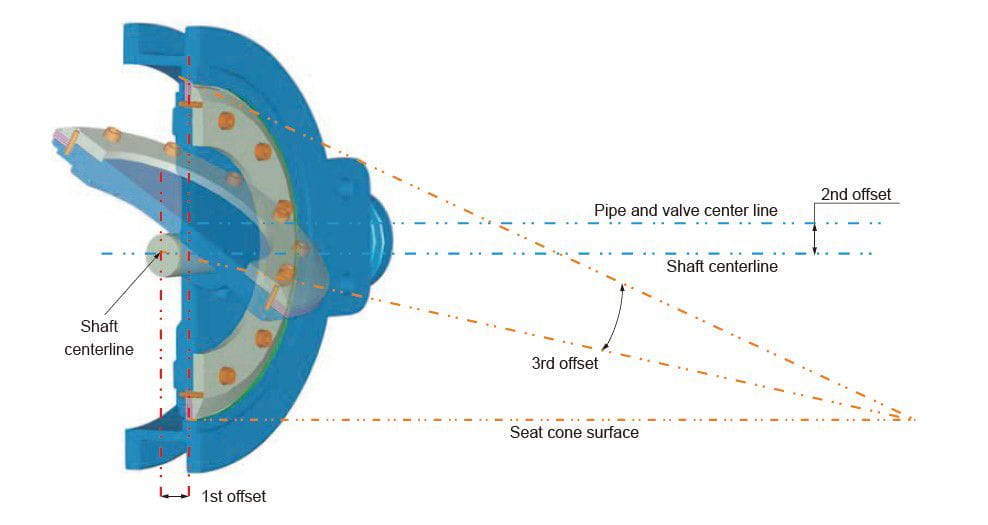

Compared with Concentric Butterfly Valves, they have unique design of offsets between shaft/disc/seat

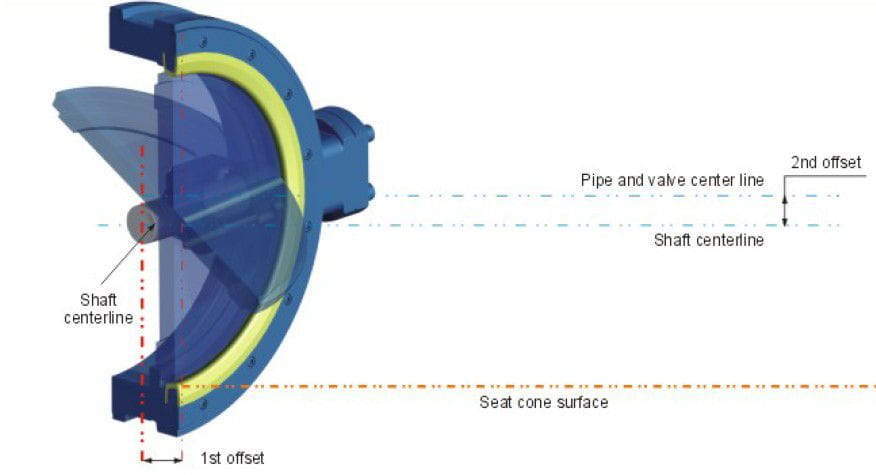

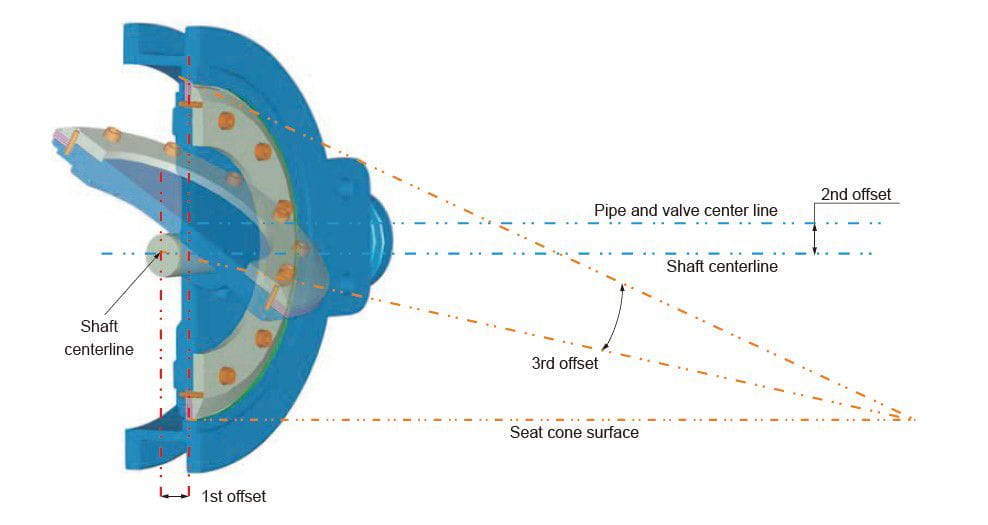

Offsets of butterfly valves:

1st offset: shaft centerline behind disc centerline, it can reduce the contact between disc and seat fore fully close, and allow for a continuous engagement of the seating surface.

2nd offset: shaft centerline offset from centerline of the valve and pipe, the sealing surface is linear so when open the valve the disc seal will quickly leave the seat and it can significantly reduce the friction/wear of sealing surfaces

3rd offset: the disc seat contact axis is offset from the pipe axis, minimizing the contact of seats and having better sealing performance.

Double Eccentric Butterfly Valve:

With 2 offsets, long working life and suitable for frequent operation service but sealing relies on elastic deformation between disc and seat, metal seat sealing performance is not as good as soft seat therefore PTFE seat is more often applied, and working pressure is normally under 300LB.

Triple Eccentric Butterfly Valve:

With 3 offsets, normally with metal seats and it makes triple offset butterfly valves suitable for wide temperature and pressure ranges.

If you need any support about our High-Performance Butterfly Valves, pls contact [email protected]!

Double Offset Butterfly Valve (Soft Seat)

Triple Offset Butterfly Valve (Metal Seat)

Compared with Concentric Butterfly Valves, they have unique design of offsets between shaft/disc/seat

Offsets of butterfly valves:

1st offset: shaft centerline behind disc centerline, it can reduce the contact between disc and seat fore fully close, and allow for a continuous engagement of the seating surface.

2nd offset: shaft centerline offset from centerline of the valve and pipe, the sealing surface is linear so when open the valve the disc seal will quickly leave the seat and it can significantly reduce the friction/wear of sealing surfaces

3rd offset: the disc seat contact axis is offset from the pipe axis, minimizing the contact of seats and having better sealing performance.

Double Eccentric Butterfly Valve:

With 2 offsets, long working life and suitable for frequent operation service but sealing relies on elastic deformation between disc and seat, metal seat sealing performance is not as good as soft seat therefore PTFE seat is more often applied, and working pressure is normally under 300LB.

Triple Eccentric Butterfly Valve:

With 3 offsets, normally with metal seats and it makes triple offset butterfly valves suitable for wide temperature and pressure ranges.

If you need any support about our High-Performance Butterfly Valves, pls contact [email protected]!

Next: How to Select between Gate Valves and Butterfly Valves

Previous: Soft Seal Material Options for Ball Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China