Functions and Advantages of Knife Gate Valves

Mar 04, 2024

In industrial pipeline systems, the knife gate valve serves as a vital control device, widely employed across various sectors due to its unique design and performance. This article aims to delve into the functions, advantages, and operating principles of the knife gate valves.

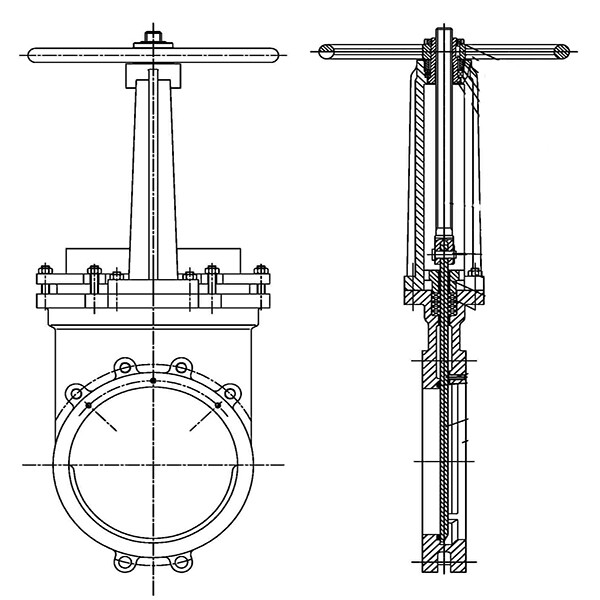

Operating Principle of Knife Gate Valve

The operation of a knife gate valve relies on the coordination between the handwheel, valve body, and internal control mechanism. Specifically:

- By manipulating the handwheel, the internal control mechanism undergoes a series of physical movements, ultimately opening or closing the valve to control the flow within the pipeline.

- Rotation of the handwheel actuates internal levers and gears, inducing a synchronized movement that rapidly alters the blocking mechanism inside the valve, facilitating valve opening or closure.

- This operational method is efficient and expeditious, enabling tasks to be completed swiftly and enhancing the overall efficiency of pipeline systems.

Advantages of Knife Gate Valve

The knife gate valve boasts numerous advantages, making it highly favored in industrial applications:

- Simple Structure: Its straightforward design facilitates manufacturing, installation, and maintenance, reducing costs and operational complexities.

- Rapid Response: Swift opening and closing actions enable prompt flow cutoff, ensuring the safety of pipeline systems.

- Excellent Sealing Performance: Utilization of metal or elastic sealing gaskets effectively prevents medium leakage, maintaining system integrity.

- Superior Wear Resistance: Hard materials used for valve blade and seat sealing surfaces impart excellent resistance to abrasion, extending service life even under challenging operating conditions.

- Compact and Lightweight: Its compact design and lightweight nature ease installation and maintenance, conserving space and manpower resources.

Functions of Knife Gate Valve

The knife gate valve primarily functions in fluid control within pipeline systems, including but not limited to:

- Mining, Coal Washing, Steel Industry: Utilized in coal washing pipelines, slag slurry pipelines, ash discharge pipelines, and more.

- Purification Systems: Applied in the treatment of wastewater, slurry, pollutants, and clarified water containing suspended solids.

- Papermaking Industry: Employed for processing pulp of any concentration and pulp-water mixtures.

- Power Plant Ash Removal: Utilized for handling ash slurry liquids.

In conclusion, the knife gate valve plays an indispensable role in industrial pipeline control, owing to its exceptional performance and user-friendly operation. With its simple structure, rapid response, superior sealing, wear resistance, and versatile functionality, it stands as an ideal choice for pipeline control across various industries, ensuring reliable operational support.

Next: Check Valve Placement and Coordination in Pipeline Systems

Previous: Mitigating Corrosion Risks in Industrial Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China