Forged Stainless Steel Ball Valves: Advancing Pipeline Technology

Feb 28, 2024

Forged stainless steel ball valves represent cutting-edge technology in the international standards for valve development. Specifically engineered for the transportation of petroleum and natural gas in long-distance pipelines, as well as urban gas pipeline systems, these ball valves are meticulously crafted to address the unique challenges posed by long-distance pipeline applications. This article delves into the key aspects of forged stainless steel ball valves, including their features, materials, and performance characteristics, elucidating their significance in industrial settings.

1. Features and Applications

Forged stainless steel ball valves are designed to withstand the rigors of long-distance pipeline transportation. They are equipped with various operational options, such as manual worm gear drive, pneumatic, electric, gas/hydraulic linkage, and specialized control forms. Their high-temperature and wear-resistant properties make them indispensable in industrial applications where reliability and durability are paramount.

4. Materials and Performance Characteristics

These valves exhibit remarkable temperature resistance, withstanding temperatures up to 425°C, and boast a hardness coefficient ranging between 65-70. The bidirectional valve seat, supported by spring force, ensures tight sealing around the ball core. The use of hard alloy sealing materials, along with spray-welded ball surfaces, enhances their hardness and durability. Additionally, graphite-sealed valve seats guarantee stability under high-temperature conditions.

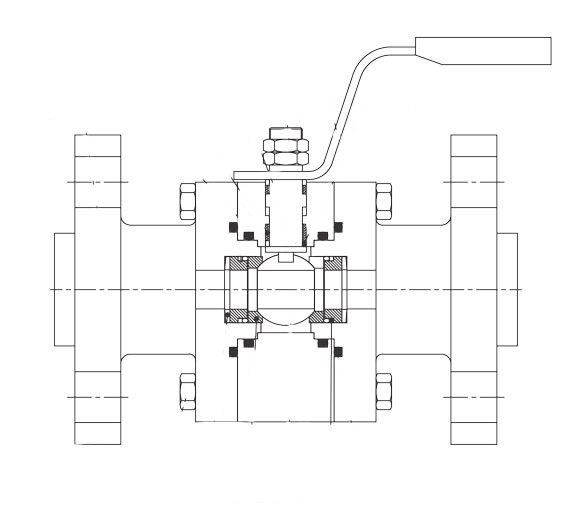

3. Structural Design and Reliability

Forged steel construction imparts superior strength and stiffness to the valve body, enabling it to withstand maximum rated working pressures without the defects associated with castings. Carefully engineered internals ensure reliability across various operating conditions. The split-body design, featuring ample wall thickness and high-strength connecting bolts, facilitates ease of maintenance and enhances stress resistance.

4. Sealing Performance and Protective Measures

Utilizing a bottom-sealed structure, these valves ensure reliable sealing at the packing location. They can be customized to accommodate media containing solid particles or operating in high-temperature environments. The spring-loaded movable metal structure of the valve seat ensures rational sealing force, flexible operation, and dependable sealing. However, protecting the sealing surface from wear, flushing, and erosion under high pressure is essential for long-term performance.

Forged stainless steel ball valves are at the forefront of valve technology, offering unparalleled performance and reliability in industrial applications. By understanding their features, materials, and performance characteristics, stakeholders can leverage these valves to enhance the safety and efficiency of pipeline operations. Adhering to stringent standards for usage, installation, and maintenance is crucial for maximizing the longevity and effectiveness of forged stainless steel ball valves in industrial settings.

Next: Ensuring Safe and Stable Installation of Wafer Check Valves

Previous: Three-Way Ball Valves: Streamlined Fluid Control Solutions

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China