Floating Ball Valves: Structure, Features and Safety Design

Dec 14, 2023

Floating ball valves stand out as a widely utilized type of ball valves across diverse industries, distinguished by their innovative design incorporating a floating ball. This article delves into an in-depth exploration of the structure, distinctive characteristics, industrial applications, and safety design features inherent to this kind of ball valve.

Basic Principles of Floating Ball Valves

The ball in a floating ball valve is designed to float, enabling it to generate displacement and tightly press against the sealing surface at the outlet under the influence of medium pressure, ensuring a secure seal.

Structural Features and Application Range

Floating ball valves have a simple structure and excellent sealing properties, making them suitable for medium to low-pressure conditions. Key characteristics include:

The Floating Ball Valves Features

Floating ball valves, known for their distinctive design and versatile functionality, boast several key features that contribute to their widespread use in various industries. Here, we explore these notable features:

Structural Design of Floating Ball Valves

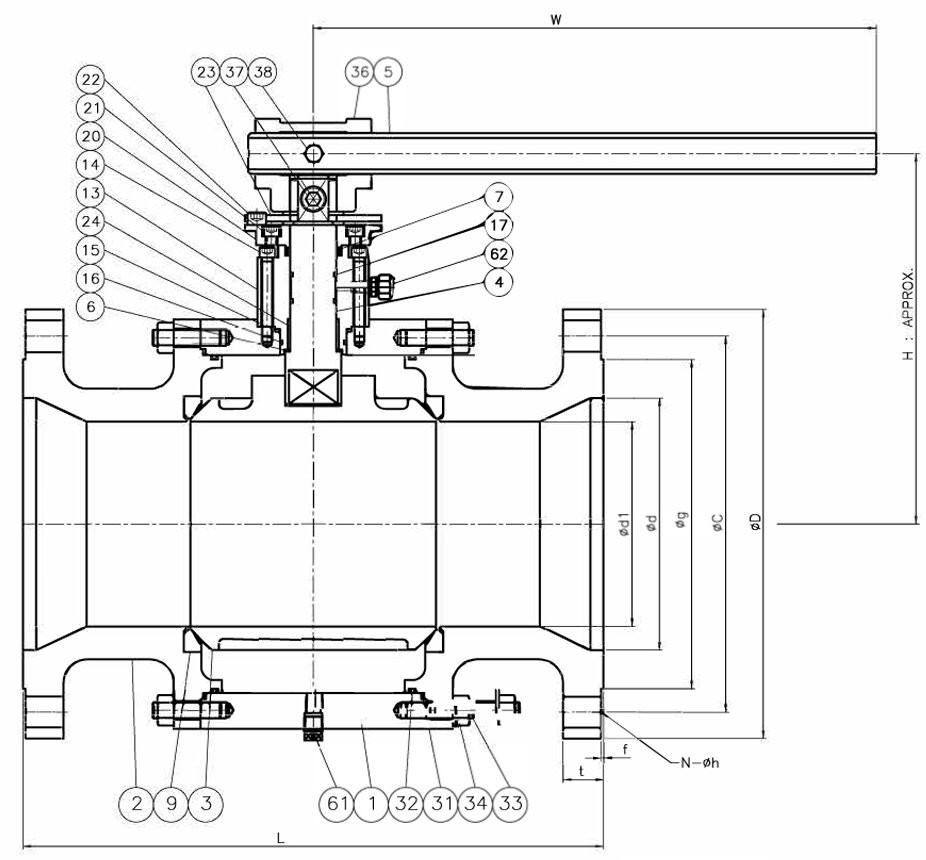

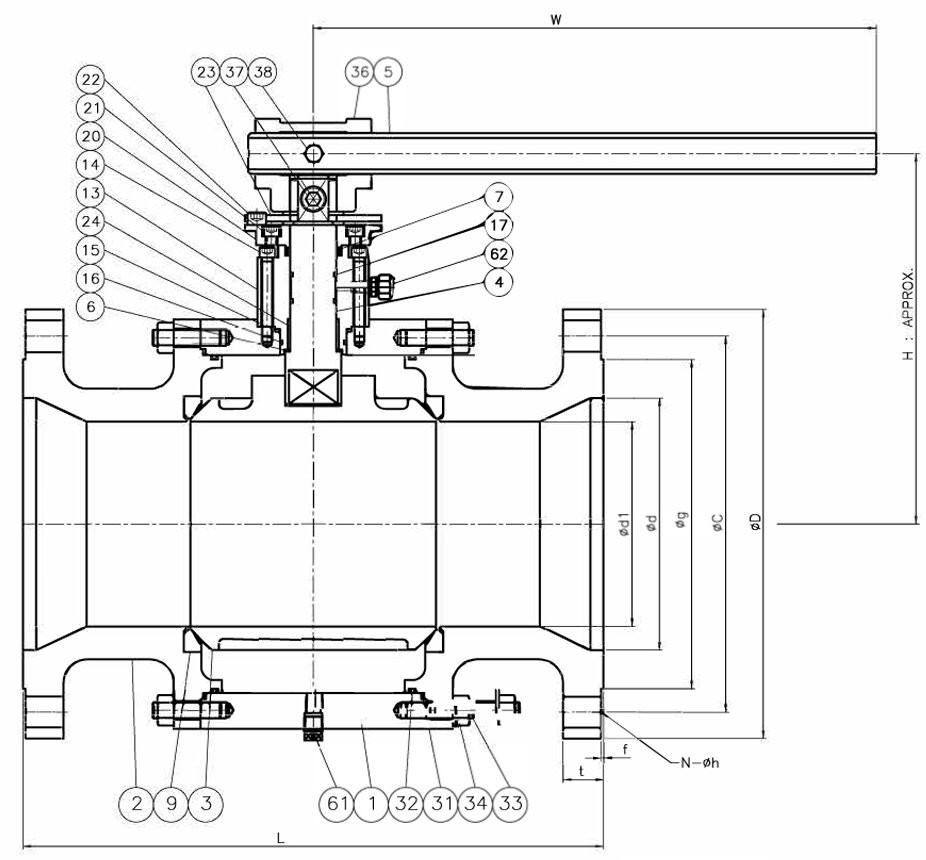

The structural design of floating ball valves is a crucial aspect that influences their performance, reliability, and efficiency in fluid control systems. Here, we delve into the key elements of the structural design of floating ball valves:

Floating ball valves stand as critical components in a multitude of industries, where their distinctive design and robust safety features are indispensable. These valves play a pivotal role in ensuring the utmost reliability, efficiency, and safety within complex fluid control systems.

Basic Principles of Floating Ball Valves

The ball in a floating ball valve is designed to float, enabling it to generate displacement and tightly press against the sealing surface at the outlet under the influence of medium pressure, ensuring a secure seal.

Structural Features and Application Range

Floating ball valves have a simple structure and excellent sealing properties, making them suitable for medium to low-pressure conditions. Key characteristics include:

- Compact structure, reliable sealing, and ease of operation and maintenance.

- Applicability to general working mediums such as water, solvents, acids, natural gas, and challenging conditions like oxygen, hydrogen peroxide, methane, and ethylene.

- The valve body can be integral or modular.

The Floating Ball Valves Features

Floating ball valves, known for their distinctive design and versatile functionality, boast several key features that contribute to their widespread use in various industries. Here, we explore these notable features:

Minimal Flow Resistance: In various valve types, ball valves exhibit the least flow resistance. When fully open, the ball valve's channel, valve body channel, and connecting pipe diameter are equal, allowing the medium to flow through with minimal loss.

Quick Opening and Closing: A 90° rotation fully opens or closes the ball valve, ensuring rapid operation. Compared to gate valves and globe valves of the same specifications, ball valves are smaller and lighter, facilitating easy pipeline installation.

Quick Opening and Closing: A 90° rotation fully opens or closes the ball valve, ensuring rapid operation. Compared to gate valves and globe valves of the same specifications, ball valves are smaller and lighter, facilitating easy pipeline installation.

Structural Design of Floating Ball Valves

The structural design of floating ball valves is a crucial aspect that influences their performance, reliability, and efficiency in fluid control systems. Here, we delve into the key elements of the structural design of floating ball valves:

1. Preventing Handle Misoperation

Ordinary ball valves risk misoperation due to the square connection between the handle and the valve stem. Floating ball valves with a flat square connection eliminate the possibility of handle misconnection.

2. Locking Mechanism

Manual ball valves can be locked in fully open or closed positions, preventing unauthorized personnel from manipulating the valve. This is particularly useful in hazardous environments with explosive oils or chemical pipelines.

3. Blow-out Proof Stem

A shoulder is incorporated at the lower part of the valve stem to prevent the stem from flying out due to abnormal pressure increases.

A stop thrust bearing is placed at the contact point between the lower shoulder and the valve body to create an inverted sealing seat, preventing leaks.

4. Anti-Static Design

A static electricity spring is introduced between the valve stem and ball to prevent static electricity generation due to friction, minimizing the risk of ignition in flammable mediums.

5. Leak-Proof Valve Body Sealing Structure

The connection between the valve body and side valve body relies on metallic sealing, ensuring no external leakage. This design is especially effective in high-temperature, fire, and vibration-prone environments.

Ordinary ball valves risk misoperation due to the square connection between the handle and the valve stem. Floating ball valves with a flat square connection eliminate the possibility of handle misconnection.

2. Locking Mechanism

Manual ball valves can be locked in fully open or closed positions, preventing unauthorized personnel from manipulating the valve. This is particularly useful in hazardous environments with explosive oils or chemical pipelines.

3. Blow-out Proof Stem

A shoulder is incorporated at the lower part of the valve stem to prevent the stem from flying out due to abnormal pressure increases.

A stop thrust bearing is placed at the contact point between the lower shoulder and the valve body to create an inverted sealing seat, preventing leaks.

4. Anti-Static Design

A static electricity spring is introduced between the valve stem and ball to prevent static electricity generation due to friction, minimizing the risk of ignition in flammable mediums.

5. Leak-Proof Valve Body Sealing Structure

The connection between the valve body and side valve body relies on metallic sealing, ensuring no external leakage. This design is especially effective in high-temperature, fire, and vibration-prone environments.

Floating ball valves stand as critical components in a multitude of industries, where their distinctive design and robust safety features are indispensable. These valves play a pivotal role in ensuring the utmost reliability, efficiency, and safety within complex fluid control systems.

Next: The Unrivaled Simplicity and Convenience of Three-Piece Ball Valves

Previous: Pneumatic Ball Valve Features and Pipeline Applications

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China