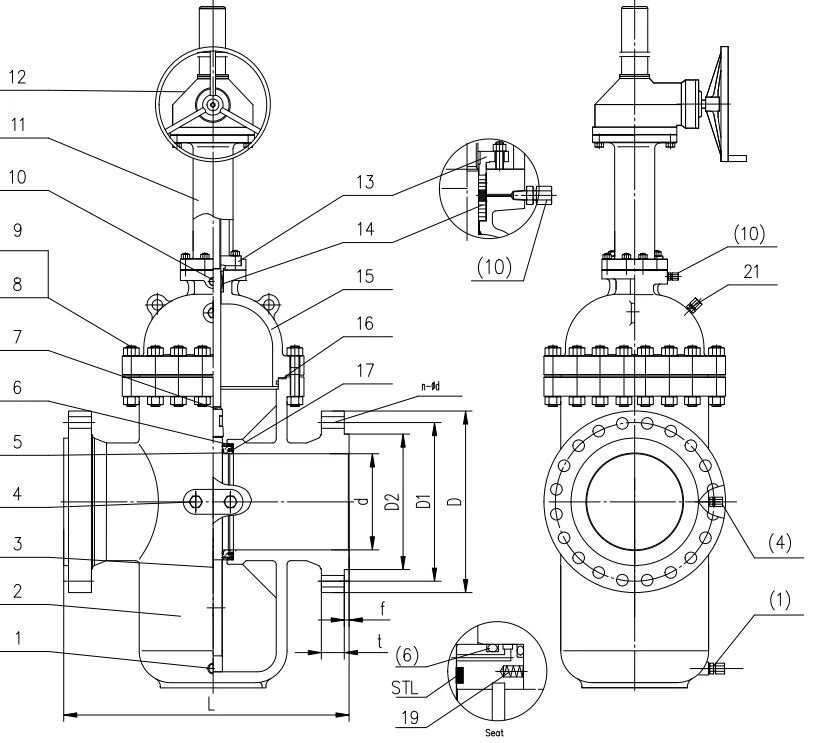

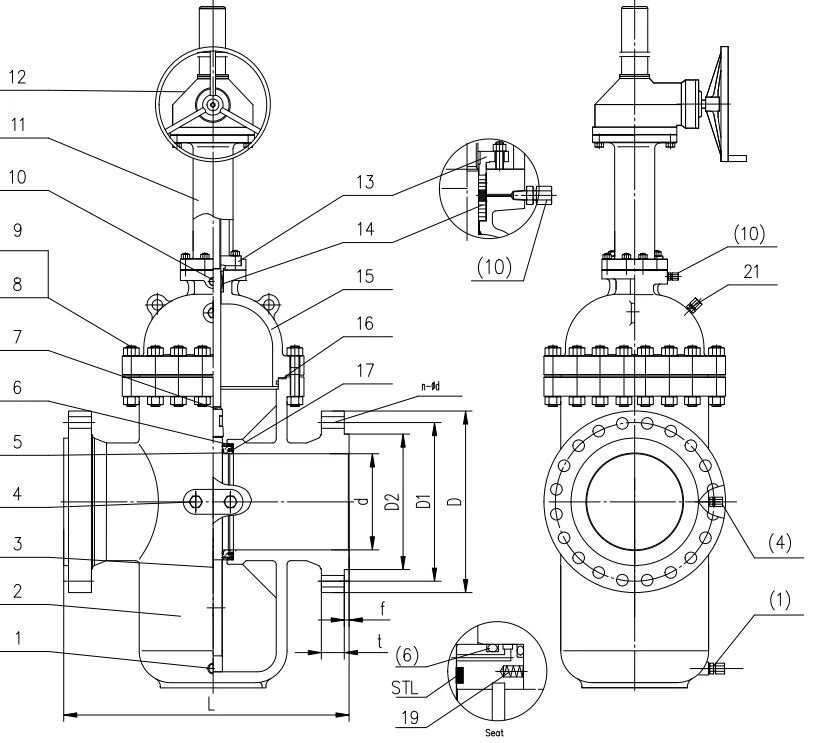

Exploring the Versatility of Slab Gate Valves

Dec 12, 2023

Slab gate valve, renowned for their parallel gate design, has become an indispensable gate valve in various industries, offering a unique blend of efficiency and adaptability. This article delves into the features, applications, and selection principles of these gate valves, shedding light on their widespread use and the nuanced considerations that guide their deployment.

Key Features of Slab Gate Valves

Slab gate valves, known for their innovative design and efficient functionality, boast several key features that contribute to their widespread use in various industries. Here are the essential features of slab gate valves:

Applications of Slab Gate Valves

Slab gate valves, with their innovative design and robust features, find widespread applications across various industries. Their adaptability and efficiency make them a preferred choice for fluid control in diverse settings.

Selection Principles for Slab Gate Valves

Choosing the appropriate slab gate valve is crucial for ensuring efficient fluid control in various applications. Consideration of specific requirements and operating conditions is essential.

1. Petroleum and Natural Gas Pipelines: Opt for single or dual-gate slab gate valves based on pipeline needs.

2. Refined Oil Product Pipelines and Storage: Choose slab gate valves without flow-through holes, with either single or dual gates.

3. Oil and Gas Wellhead Equipment: Select slab gate valves with a concealed stem and flow-through holes in single or dual gates.

4. Pipelines with Suspended Particle Media: Opt for knife-edge slab gate valves for enhanced particle management.

5. Urban Gas Pipelines: Consider soft-sealed stem slab gate valves with single or dual gates for urban gas pipelines.

6. Water Supply Projects: Choose slab gate valves with non-flow-through holes and a visible stem, available with single or dual gates.

In conclusion, slab gate valves present a diverse array of types and find widespread application across various industries. Their unique features and the selection principles outlined above offer engineering professionals flexible and efficient solutions for different projects. As these valves continue to evolve, their role in optimizing industrial processes remains paramount.

Key Features of Slab Gate Valves

Slab gate valves, known for their innovative design and efficient functionality, boast several key features that contribute to their widespread use in various industries. Here are the essential features of slab gate valves:

- Floating Valve Seat Structure: The incorporation of a floating valve seat structure, coupled with O-ring seals, ensures reliable bidirectional sealing. This design enhances the overall sealing performance of the valve.

- Reduced Actuation Torque: Slab gate valves are designed with a reduced actuation torque, making the opening and closing operations smoother and more energy-efficient. This feature contributes to the longevity of the valve.

- Linear Passage Design: When fully open, slab gate valves provide a smooth and linear passage for fluid flow. This design minimizes pressure loss, making them suitable for applications where efficient flow is crucial.

- Self-Sealing Packing Structure: The self-sealing capability of the packing structure minimizes the need for frequent adjustments, ensuring a consistent and reliable seal over an extended period. This feature contributes to the valve's low maintenance requirements.

- Auxiliary Seal Grease Injection: Equipped with an auxiliary seal grease injection structure in the packing chamber, slab gate valves offer enhanced sealing performance. This feature helps maintain a secure seal, reducing the risk of leakage.

- Automatic Pressure Relief: The ability of slab gate valves to automatically relieve high pressure within the cavity during closure enhances operational safety. This feature is particularly valuable in applications where pressure control is critical.

Applications of Slab Gate Valves

Slab gate valves, with their innovative design and robust features, find widespread applications across various industries. Their adaptability and efficiency make them a preferred choice for fluid control in diverse settings.

- Petroleum and Natural Gas Pipelines: Ideal for controlling the flow in pipelines transporting petroleum and natural gas.

- Refined Oil Product Pipelines and Storage: Well-suited for both transportation and storage facilities in the refined oil products sector.

- Oil and Gas Wellhead Equipment: Recommended for wellhead equipment in oil and gas extraction operations.

- Pipelines with Suspended Particle Media: Specifically designed for pipelines dealing with media containing suspended particles.

- Urban Gas Pipelines: Applicable in urban gas distribution networks.

- Water Supply Projects: Ideal for urban water supply projects, offering reliable performance.

Selection Principles for Slab Gate Valves

Choosing the appropriate slab gate valve is crucial for ensuring efficient fluid control in various applications. Consideration of specific requirements and operating conditions is essential.

1. Petroleum and Natural Gas Pipelines: Opt for single or dual-gate slab gate valves based on pipeline needs.

2. Refined Oil Product Pipelines and Storage: Choose slab gate valves without flow-through holes, with either single or dual gates.

3. Oil and Gas Wellhead Equipment: Select slab gate valves with a concealed stem and flow-through holes in single or dual gates.

4. Pipelines with Suspended Particle Media: Opt for knife-edge slab gate valves for enhanced particle management.

5. Urban Gas Pipelines: Consider soft-sealed stem slab gate valves with single or dual gates for urban gas pipelines.

6. Water Supply Projects: Choose slab gate valves with non-flow-through holes and a visible stem, available with single or dual gates.

In conclusion, slab gate valves present a diverse array of types and find widespread application across various industries. Their unique features and the selection principles outlined above offer engineering professionals flexible and efficient solutions for different projects. As these valves continue to evolve, their role in optimizing industrial processes remains paramount.

Next: Pneumatic Ball Valve Features and Pipeline Applications

Previous: Choosing Between Double and Triple Offset Butterfly Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China