Exploring the Differences Between Plug Valves and Ball Valves

Apr 17, 2024

Plug valves and ball valves are two of the most common types of valves in industrial pipeline systems, playing vital roles in fluid control. While both plug valve and ball valve are utilized to manage fluid flow, they exhibit significant differences in their working principles, advantages, disadvantages, and suitable applications. Let's delve deeper into understanding these valves.

1. Working Principles

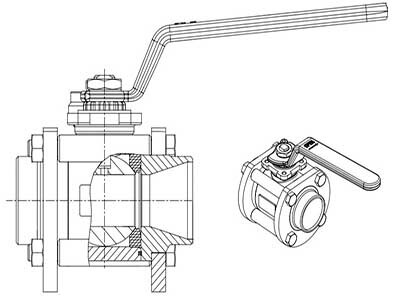

Ball Valve: A ball valve features a spherical closure element that rotates 90° around its axis to control flow. Its simple design and swift operation make it widely applicable across various industrial sectors. The rotational movement of the ball provides rapid shut-off capability and ensures reliable sealing when closed.

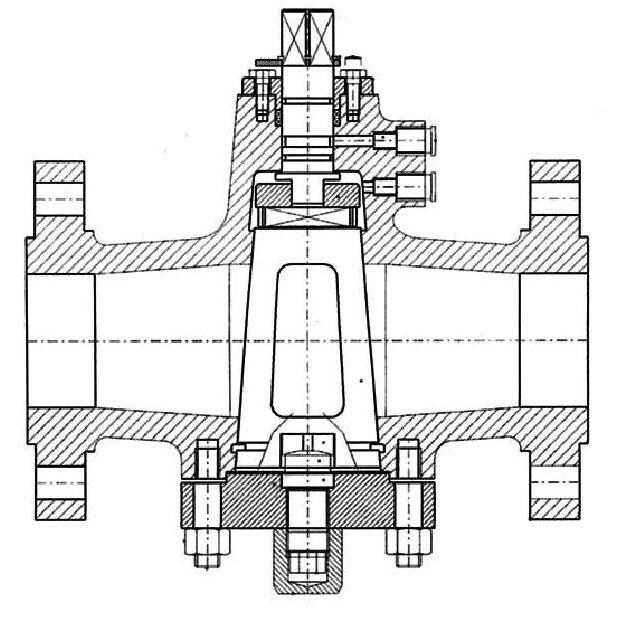

Plug Valve: A plug valve utilizes a cylindrical or tapered plug as the closure mechanism, which is rotated within the valve body to either open or close the passage. Due to the larger sealing surface area provided by the plug, plug valves offer better sealing performance and reliability, especially in high-pressure and high-temperature environments.

Comparison of Advantages and Disadvantages

Ball Valve:

Advantages: Simple and quick operation, suitable for general fluid control applications, compact design, and easy maintenance.

Disadvantages: May have reduced sealing performance in high-pressure or high-temperature environments, not ideal for applications requiring extremely high sealing performance.

Plug Valve:

Advantages: Larger sealing surface area, suitable for high-pressure and high-temperature environments, more reliable sealing performance, and strong flow control capability.

Disadvantages: Relatively complex operation, particularly prone to the effects of the plug's own weight in large-diameter valves.

Suitable Applications

Ball Valve: Ball valves are suitable for general industrial applications, such as chemical, pharmaceutical, and water treatment industries, as well as situations where simple operation, moderate flow control requirements, and relatively lower sealing performance are acceptable.

Plug Valve: Plug valves are ideal for applications requiring higher sealing performance, strict flow control, and operation in high-pressure and high-temperature environments. They are commonly used in industries such as petroleum, natural gas pipeline transportation, and chemical process industries.

When selecting the appropriate valve type, it is essential to consider factors such as process requirements, fluid characteristics, operating environment, and safety requirements. Whether it's a ball valve or a plug valve, each has its place in fluid control applications, ensuring the safety and stability of pipeline systems when used correctly.

Next: Common Methods for Diagnosing Leakage in Industrial Valves

Previous: Disassembly and Packing Replacement Guide of Butterfly Valve

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China