Exploring Different Drive Modes for Industrial Valves

May 11, 2024

On this page

Industrial valves play a pivotal role in industrial processes and fluid control systems, offering a diverse array of drive modes such as electric, pneumatic, hydraulic, and manual drives. These drive modes provide unique advantages and characteristics, catering to a wide range of industrial applications. In this article, we delve into the intricacies of these different industrial valve drive modes, exploring their features and applications in detail.

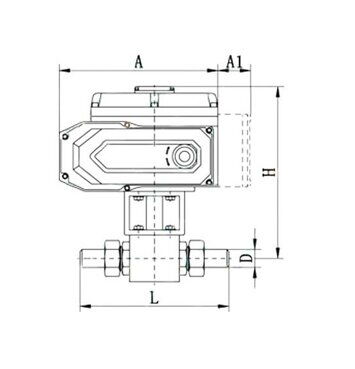

Electrically driven valves streamline operations with swift opening/closing, reduced labor, remote accessibility, and automation support. Despite benefits like ease of power access, challenges like complex construction and operational issues in certain environments require careful management.

- Rapid Opening and Closing: Electric drive facilitates swift valve operation, significantly reducing the time required for opening and closing, thereby enhancing production efficiency.

- Reduced Labor Intensity: These actuators lessen the labor intensity for operators, particularly suitable for high-pressure and large-diameter valves, thus improving workplace safety.

- Wide Applicability: They can be installed in locations where manual operation is impractical or difficult to access, enabling remote manipulation with unrestricted installation height, enhancing operational flexibility.

- Automation Facilitation: Electrically driven valves promote system automation, reducing manual intervention and minimizing operational errors.

- Ease of Power Accessibility: Compared to air and liquid sources, electricity is readily accessible, simplifying wiring installation and maintenance, leading to cost savings.

However, electrically driven valves have some drawbacks, including complex construction, operational challenges in humid environments, and the necessity for explosion-proof measures when handling inflammable media.

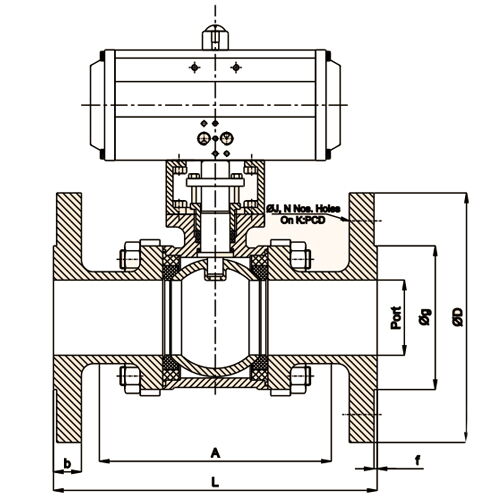

Pneumatic and hydraulic valves utilize air, water, or oil pressure as power sources, employing cylinder and piston movements to actuate valves. Pneumatic valves typically operate at air pressures below 0.8 MPa, while hydraulic valves operate with water or oil pressures ranging from 2.5 MPa to 25 MPa. Pneumatic valves are suitable for driving diaphragm or rotary valves, while hydraulic valves, with their greater driving force, are applicable for large-diameter valves.

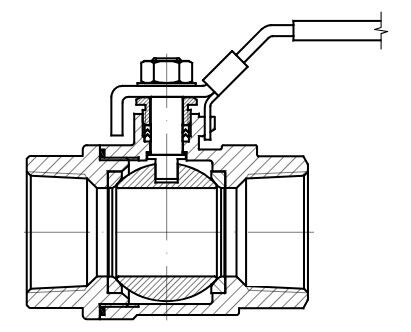

Manual valves represent a fundamental drive mode, comprising direct operation using handwheels, levers, or wrenches, as well as operation through transmission mechanisms. When the valve's opening torque is high, gear or worm gear drives are employed to achieve labor-saving purposes. Gear drives include straight-tooth spur gear drives suitable for gate valves and globe valves, while worm gear drives are suitable for plug valves, ball valves, and butterfly valves.

Different valve drive modes offer distinct advantages tailored to specific industrial applications and requirements. The selection of an appropriate drive mode can enhance system stability, operational efficiency, and safety. As technology continues to advance, valve drive technologies will undergo further innovation and refinement to meet evolving demands in industrial production.

Next: Understand Differences Between Globe Valves and Gate Valves

Previous: List of our Gate, Globe, Check Valves in Stock

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China