Essential Tips for Forged Steel Gate Valve Operation and Maintenance

Feb 24, 2024

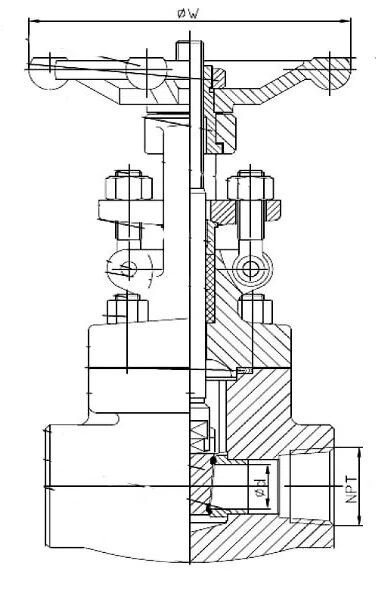

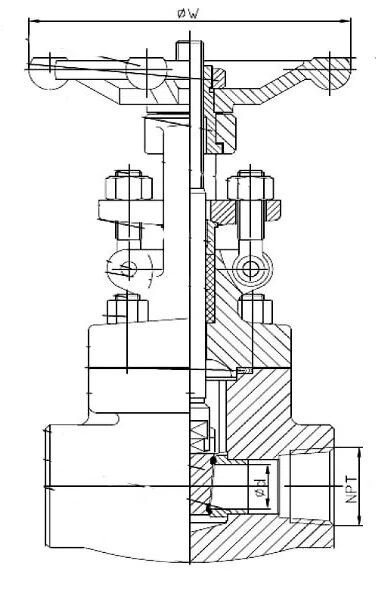

Forged steel gate valves are indispensable key devices in pipeline systems, with their movement direction perpendicular to the fluid direction, allowing for full open and full close functions. In the conveyance of various media, the selection and maintenance of forged steel gate valves are crucial, as they not only affect the performance and stability of equipment but also directly impact the normal operation of industrial production. Here are some key considerations for operating and maintaining forged steel gate valves:

Operating Considerations

In addition to the open and close operations and greasing procedures, attention to certain detailed issues is crucial to ensure the normal operation and extended service life of forged steel gate valves. Here are some key considerations during the operation of forged steel gate valves:

Maintenance Suggestions

In addition to operational considerations, regular maintenance is equally essential for maintaining the good condition and prolonging the service life of forged steel gate valves. Here are some maintenance suggestions:

In conclusion, following these guidelines and maintenance suggestions is crucial for maximizing the efficiency and reliability of forged steel gate valves. By doing so, industries can ensure smooth equipment operation, enhance productivity, and prevent disruptions in production processes. With proper care, forged steel gate valves remain integral components in maintaining pipeline system integrity across diverse industrial sectors.

Operating Considerations

In addition to the open and close operations and greasing procedures, attention to certain detailed issues is crucial to ensure the normal operation and extended service life of forged steel gate valves. Here are some key considerations during the operation of forged steel gate valves:

- Open and Close Operations: When performing maintenance or servicing, it is essential to adjust forged steel gate valves to the closed position. This helps prevent wastage of lubricating grease and maintains sealing performance to ensure the equipment's normal operation.

- Greasing Operation: During greasing, it is important to ensure uniform greasing effects, allowing the lubricating grease to fully lubricate the valve surface, ensuring smooth valve operation and prolonged service life.

- Draining and Pressure Relief: After performing valve hydrostatic tests, gases and moisture inside the valve cavity will increase in pressure due to rising environmental temperatures. Before greasing, it is necessary to drain and relieve pressure to facilitate smooth greasing operations.

- Valve Alignment: Adjust the valve limit switch to ensure that the valve diameter is aligned with the seat seal, avoiding excessive tightness or looseness to ensure the equipment's safe operation.

- Flow Direction Identification: Pay attention to the arrow markings on the valve body, understanding the direction of the seal seat and the valve's self-draining direction to ensure the valve's normal operation and accurate control of fluid flow direction.

- Valve Stem Lubrication: Maintain lubrication of the valve stem area to reduce friction resistance during operation and ensure smooth equipment operation.

Maintenance Suggestions

In addition to operational considerations, regular maintenance is equally essential for maintaining the good condition and prolonging the service life of forged steel gate valves. Here are some maintenance suggestions:

1. Moisture Protection: Prevent water ingress into the electric head and transmission mechanism, especially during the rainy season, by enhancing waterproof measures for valve equipment to prevent equipment damage due to water ingress.

2. Regular Greasing: For valves frequently operated, it is recommended to lubricate at least once a month to maintain smooth operation and keep valve components in good condition.

3. Greasing Quantity Attention: Ensure an appropriate amount of grease is applied, and operators should control the amount of grease during greasing to avoid over-greasing or under-greasing.

4. Uniform Grease Discharge: During normal greasing, ensure that the grease discharges evenly from the grease fitting. If any abnormality is detected, prompt inspection and rectification should be carried out.

5. Regular Cleaning: Regularly clean forged steel gate valves to prevent debris from entering and affecting the normal operation of equipment.

6. Valve Stem Lubrication: Maintain lubrication of the valve stem area to reduce friction resistance during operation and extend the valve's service life.

2. Regular Greasing: For valves frequently operated, it is recommended to lubricate at least once a month to maintain smooth operation and keep valve components in good condition.

3. Greasing Quantity Attention: Ensure an appropriate amount of grease is applied, and operators should control the amount of grease during greasing to avoid over-greasing or under-greasing.

4. Uniform Grease Discharge: During normal greasing, ensure that the grease discharges evenly from the grease fitting. If any abnormality is detected, prompt inspection and rectification should be carried out.

5. Regular Cleaning: Regularly clean forged steel gate valves to prevent debris from entering and affecting the normal operation of equipment.

6. Valve Stem Lubrication: Maintain lubrication of the valve stem area to reduce friction resistance during operation and extend the valve's service life.

In conclusion, following these guidelines and maintenance suggestions is crucial for maximizing the efficiency and reliability of forged steel gate valves. By doing so, industries can ensure smooth equipment operation, enhance productivity, and prevent disruptions in production processes. With proper care, forged steel gate valves remain integral components in maintaining pipeline system integrity across diverse industrial sectors.

Next: Exploring the Significance of Y Strainers in Fluid Control Systems

Previous: Comparing Soft Seal and Metal Seat Gate Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China