Comparing Soft Seal and Metal Seat Gate Valves

Feb 25, 2024

Soft seal gate valves and metal seat gate valves play pivotal roles in engineering applications, directly influencing the safety and efficiency of industrial production through their sealing performance. The structural disparities between the two types of gate valves highlight distinct advantages and considerations in various aspects.

1. Sealing Structure

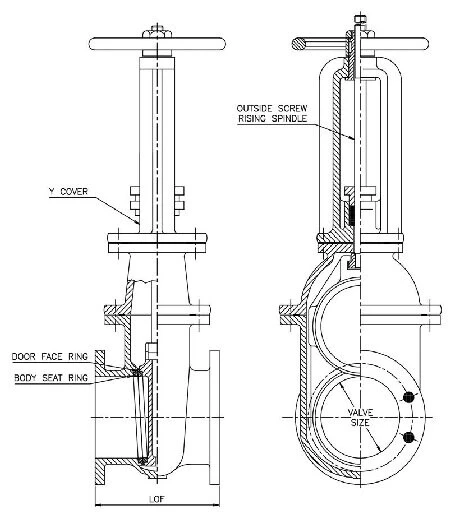

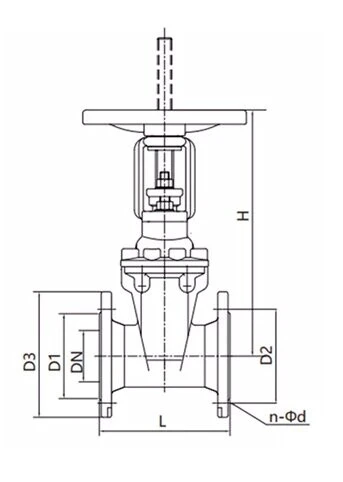

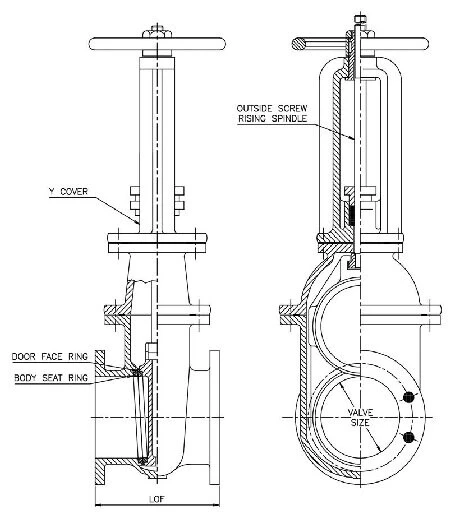

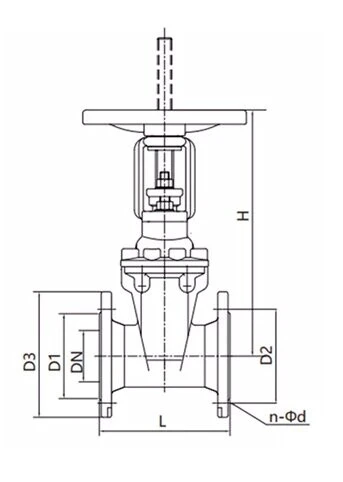

Soft seal gate valves feature a construction where one side comprises metal while the other side incorporates elastic non-metallic materials such as rubber or polytetrafluoroethylene (PTFE). This juxtaposition forms a soft-seal configuration. In contrast, metal seat gate valves incorporate metals or other rigid materials on both sides of the sealing pair, creating a solid-seal structure.

2. Construction Techniques

Metal seat gate valves are extensively utilized in challenging environments such as ultra-low temperature and pressure or highly corrosive media due to their robust structural composition. Both soft seal and metal seat valves require valve body hardening treatments during construction. However, metal seat gate valves typically entail longer production cycles owing to the necessity for extended running-in periods.

3. Operating Conditions

Soft seal gate valves are capable of achieving zero leakage, but they may experience leaks at high temperatures, necessitating additional fire safety precautions. On the contrary, metal seat valves offer greater adaptability and are suitable across a broader spectrum of temperatures and pressures. For applications involving corrosive media, metal seat gate valves are often favored due to their sturdy structural integrity.

4. Equipment Selection

The selection of gate valve types hinges on various factors such as process media, temperature, and pressure. Metal seat gate valves are generally preferred for applications involving media containing solid particles, experiencing wear, or operating at temperatures exceeding 200 degrees Celsius due to their robust structural design.

5. Service Life

Soft seal gate valves boast excellent sealing performance but are susceptible to aging and wear due to material characteristics, resulting in comparatively shorter service lives. Conversely, metal seat gate valves offer longer service lives, albeit with slightly inferior sealing performance. Nonetheless, their sturdy structural design ensures durability and reliability in demanding operational environments.

In conclusion, the contrasting structural features of soft seal and metal seat gate valves underscore distinct advantages and considerations in terms of sealing performance, operating conditions, construction techniques, and service life. Engineering applications necessitate tailored selections based on specific requirements and environmental conditions, along with comprehensive design and maintenance strategies to ensure the long-term safety and stability of gate valves.

1. Sealing Structure

Soft seal gate valves feature a construction where one side comprises metal while the other side incorporates elastic non-metallic materials such as rubber or polytetrafluoroethylene (PTFE). This juxtaposition forms a soft-seal configuration. In contrast, metal seat gate valves incorporate metals or other rigid materials on both sides of the sealing pair, creating a solid-seal structure.

2. Construction Techniques

Metal seat gate valves are extensively utilized in challenging environments such as ultra-low temperature and pressure or highly corrosive media due to their robust structural composition. Both soft seal and metal seat valves require valve body hardening treatments during construction. However, metal seat gate valves typically entail longer production cycles owing to the necessity for extended running-in periods.

3. Operating Conditions

Soft seal gate valves are capable of achieving zero leakage, but they may experience leaks at high temperatures, necessitating additional fire safety precautions. On the contrary, metal seat valves offer greater adaptability and are suitable across a broader spectrum of temperatures and pressures. For applications involving corrosive media, metal seat gate valves are often favored due to their sturdy structural integrity.

4. Equipment Selection

The selection of gate valve types hinges on various factors such as process media, temperature, and pressure. Metal seat gate valves are generally preferred for applications involving media containing solid particles, experiencing wear, or operating at temperatures exceeding 200 degrees Celsius due to their robust structural design.

5. Service Life

Soft seal gate valves boast excellent sealing performance but are susceptible to aging and wear due to material characteristics, resulting in comparatively shorter service lives. Conversely, metal seat gate valves offer longer service lives, albeit with slightly inferior sealing performance. Nonetheless, their sturdy structural design ensures durability and reliability in demanding operational environments.

In conclusion, the contrasting structural features of soft seal and metal seat gate valves underscore distinct advantages and considerations in terms of sealing performance, operating conditions, construction techniques, and service life. Engineering applications necessitate tailored selections based on specific requirements and environmental conditions, along with comprehensive design and maintenance strategies to ensure the long-term safety and stability of gate valves.

Next: Essential Tips for Forged Steel Gate Valve Operation and Maintenance

Previous: Gate Valve Leakage: Root Causes and Solutions

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China