Choosing Between Double and Triple Offset Butterfly Valves

Dec 10, 2023

Butterfly valves play a crucial role in various industrial applications, and the choice between different types of butterfly valve depends on specific process requirements, fluid characteristics, and environmental conditions. In this discussion, we explore the features and advantages of Double Offset Butterfly Valves and Triple Offset Butterfly Valves to help in making informed decisions.

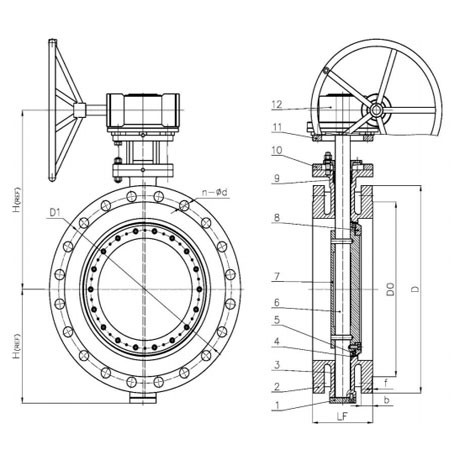

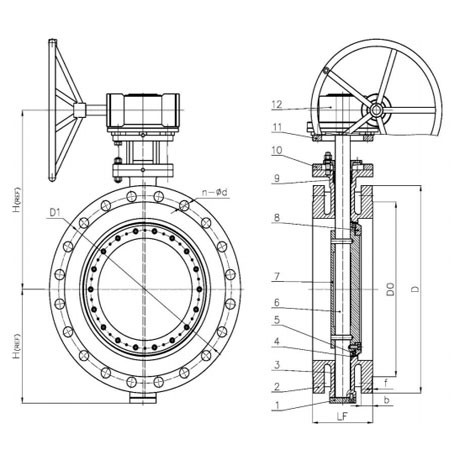

Double Offset Butterfly Valve: Advancements in Resilient Hard Sealing

The double offset butterfly valve, belonging to the category of resilient hard sealing, represents a significant improvement over its single offset counterpart. Its unique design involves the deviation of the valve stem axis both from the center of the butterfly plate and the valve body. During valve opening, the butterfly plate quickly detaches from the valve seat, reducing unnecessary compression and friction between the plate and seat. This results in decreased opening resistance, lower wear and tear, and an extended overall valve lifespan.

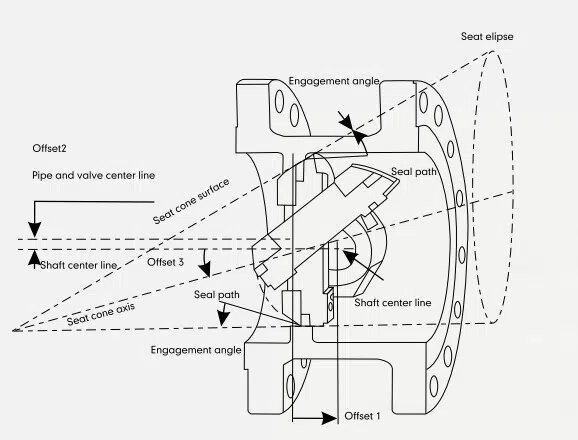

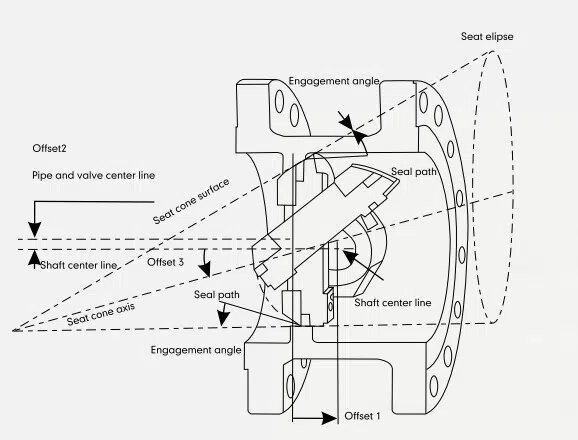

Triple Offset Butterfly Valve: High-Temperature Solution

To address the challenges faced by double offset butterfly valves under high temperatures, a hard sealing design was introduced. However, this introduced potential leakage risks. To overcome this, a soft sealing solution was implemented by adding a third offset in the design and then the triple offset butterfly valve was invented. This modification transformed the sealing surface from a regular cone to a slanted cone, creating a multi-layered structure that enhances sealing effectiveness between the butterfly plate and the valve seat. Consequently, this improves the valve's resistance to pressure and high temperatures.

Advantages of Double Offset Butterfly Valve

The double offset butterfly valve offers several advantages that make it suitable for specific applications. Here are the key advantages of double offset butterfly valves:

Advantages of Triple Offset Butterfly Valve

The triple offset butterfly valve, also known as the triple eccentric butterfly valve, offers several advantages that make it well-suited for specific applications. Here are the key advantages of triple offset butterfly valves:

In conclusion, the choice between double offset and triple offset butterfly valves should be based on a comprehensive consideration of process parameters, medium properties, operational requirements, and budget constraints. Each valve type offers distinct advantages, and understanding their features helps in making informed decisions for optimal performance in various industrial applications.

Double Offset Butterfly Valve: Advancements in Resilient Hard Sealing

The double offset butterfly valve, belonging to the category of resilient hard sealing, represents a significant improvement over its single offset counterpart. Its unique design involves the deviation of the valve stem axis both from the center of the butterfly plate and the valve body. During valve opening, the butterfly plate quickly detaches from the valve seat, reducing unnecessary compression and friction between the plate and seat. This results in decreased opening resistance, lower wear and tear, and an extended overall valve lifespan.

Triple Offset Butterfly Valve: High-Temperature Solution

To address the challenges faced by double offset butterfly valves under high temperatures, a hard sealing design was introduced. However, this introduced potential leakage risks. To overcome this, a soft sealing solution was implemented by adding a third offset in the design and then the triple offset butterfly valve was invented. This modification transformed the sealing surface from a regular cone to a slanted cone, creating a multi-layered structure that enhances sealing effectiveness between the butterfly plate and the valve seat. Consequently, this improves the valve's resistance to pressure and high temperatures.

Advantages of Double Offset Butterfly Valve

The double offset butterfly valve offers several advantages that make it suitable for specific applications. Here are the key advantages of double offset butterfly valves:

- Improved Sealing Performance: The double offset design significantly enhances sealing performance compared to single offset butterfly valves. The eccentric design of the valve seat and disc ensures a tighter fit during the closing process, reducing the likelihood of leaks.

- Wide Applicability: Double offset butterfly valves excel in applications with specific sealing requirements, making them suitable for medium to low-pressure and medium-temperature conditions. Common applications include water treatment, HVAC systems, and water supply systems.

- Relatively Lower Startup Torque: In comparison to triple offset butterfly valves, double offset valves typically have lower startup torque, contributing to reduced actuator size and power consumption.

Advantages of Triple Offset Butterfly Valve

The triple offset butterfly valve, also known as the triple eccentric butterfly valve, offers several advantages that make it well-suited for specific applications. Here are the key advantages of triple offset butterfly valves:

- Outstanding Sealing Performance: Triple offset butterfly valves achieve the highest level of sealing performance. With two offsets and one eccentric distance, these valves minimize friction between the butterfly plate and the valve seat, ensuring superior sealing. This makes them suitable for applications with extremely high sealing requirements.

- Suitability for Harsh Environments: Due to their exceptional sealing properties and structural design, triple offset butterfly valves can withstand high-temperature, high-pressure, and corrosive fluid environments. Industries such as petroleum, chemical, and metallurgy commonly utilize these valves.

- Stable Operational Performance: Despite their relatively complex structure, triple offset butterfly valves exhibit excellent stability and reliability. They are well-suited for long-term operation and applications with high-performance demands.

In conclusion, the choice between double offset and triple offset butterfly valves should be based on a comprehensive consideration of process parameters, medium properties, operational requirements, and budget constraints. Each valve type offers distinct advantages, and understanding their features helps in making informed decisions for optimal performance in various industrial applications.

Next: Exploring the Versatility of Slab Gate Valves

Previous: A Basic Understanding of Piston Check Valves

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China