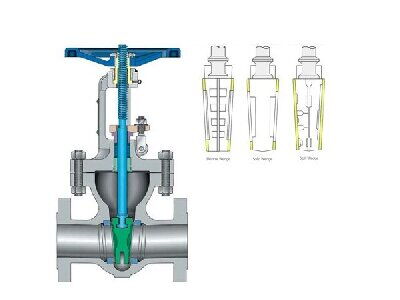

Three Common Wedge Gate Valve Disc Structures

Wedge gate valves are widely used in industrial piping systems due to their simple structure and reliable operation. The gate disc, as the core component of the wedge gate valve, directly influences the valve's sealing performance and applicability. There are three common structures for wedge gate discs: flexible wedge disc, solid wedge disc, and split wedge disc. Each structure has unique advantages and suitable applications, playing a crucial role in the valve's overall performance...