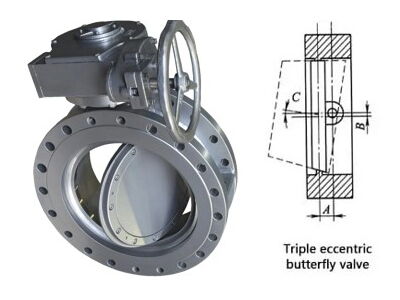

Design Structure and Features of Triple-Eccentric Butterfly Valves

Triple-eccentric butterfly valves are widely used in fluid control systems. They have unique designs and excellent sealing performance. These valves are increasingly applied in industries such as petrochemicals, power generation, metallurgy, and environmental protection. The design of these valves overcomes the limitations of traditional butterfly valves, such as sealing issues, control precision, and durability. These valves can operate reliably under high-pressure and high-temperature conditions....