Comparing Soft Seal and Metal Seat Gate Valves

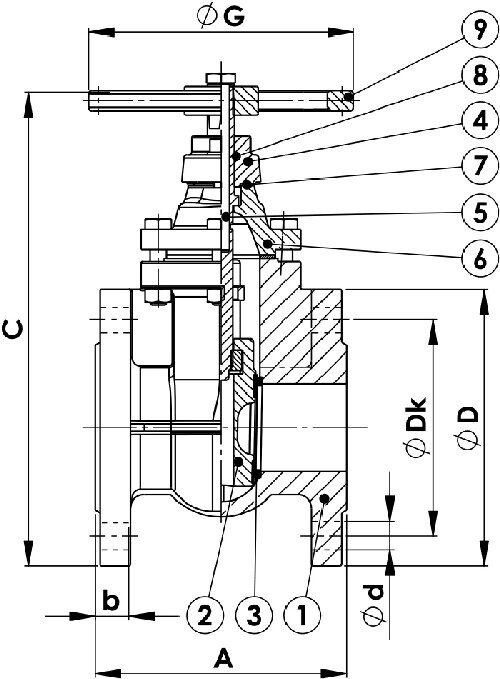

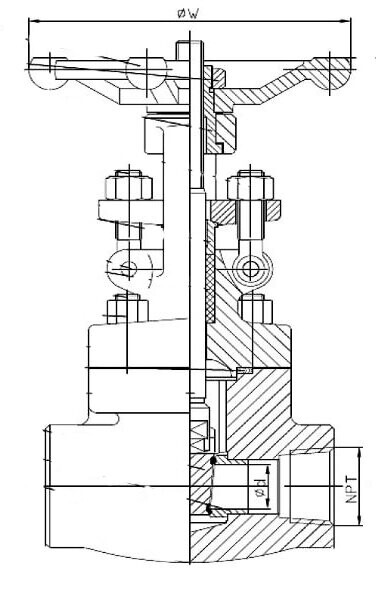

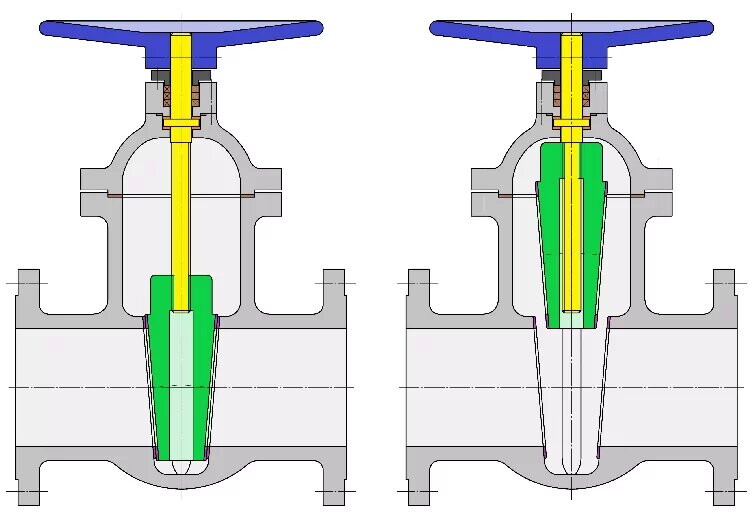

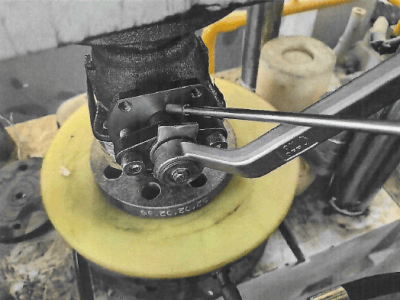

Soft seal gate valves and metal seat gate valves play pivotal roles in engineering applications, directly influencing the safety and efficiency of industrial production through their sealing performance. The structural disparities between the two types of gate valves highlight distinct advantages and considerations in various aspects. 1. Sealing Structure Soft seal gate valves feature a construction where one side comprises metal while the other side incorporates elastic non-metallic materials...