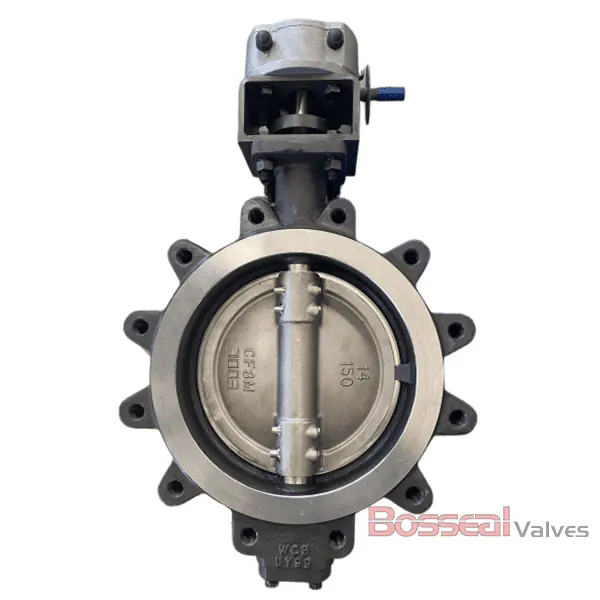

RPTFE Seated

Butterfly Valve, Double Offset, 32 Inch/DN800, Class 150 LB, Gear Operation.

1862133 High-Performance Butterfly Valve

Design Standard: API 609 Category B, EN 593

Structure: Double Offset, Double Eccentric

Body Material: ASTM A216 WCB, ASTM A890 4A, ASTM B148 C95800, ASTM A890 5A, ASTM A351 CF8, ASTM A351 CF8M, Titanium.

Nominal Size: 32 Inch, DN800

Nominal Class: Class 150 LB, PN20

Seat Type: Soft Seat

Test and Inspection: API 598, API 609

Trim Material: ASTM A351 CF8, ASTM A351 CF8M, ASTM A890 4A, ASTM A890 5A, ASTM B148 C95800, Titanium

Face to Face: API 609, EN 593

Operation: Gear

Seat: RPTFE, PPL

End Connection: Double Flanged

Key Features: Long working life for frequent operation (million cyclings), Lower torque, Replaceable seat, Tight sealing, Excellent control characteristics, Bi-direction sealing under full pressure, fire safe seat available.

Body Material: Carbon Steel, Stainless Steel, Duplex Steel, Aluminum Bronze, Titanium

Operation: Manual (lever, gear), Pneumatic Actuator, Motor Actuator

Normal Diameter: 1/2 Inch - 48 Inch (DN15 - DN1200)

Pressure Range: Class 150 LB - 300 LB

Working Temperature: -26°C - +120°C (180°C for PPL seat)

End Connection: Wafer, Lug, Flanged

The double eccentric butterfly valve stands out for its cost and space efficiency, offering a larger size range compared to other valve types. Its design allows for faster operation and minimizes restrictions and wear between the disc and seat sealing surface. This results in a longer service life and reduced total cost of ownership. The two offsets in the valve contribute to its durability and lower torque requirements, making it ideal for frequent operation. The Bosseal high-performance butterfly valve has successfully passed a million-cycle test, demonstrating its exceptional reliability and longevity.