Floating Ball Valve

- Home/

- Products/

- Ball Valves/

- Floating Ball Valve

We are a professional manufacturer of floating ball valves in China.

Design Standards: API 6D, API 608, ISO 17292, BS 5351

Size Range: 1/4 - 10 Inch

Pressure Range: Class 150-2500 LB

Material Range: Cast Steel, Forged Steel, Carbon Steel, Stainless Steel, Alloy Steel, Bronze, Ti

End Connections: Flanged (FF, RF, RTJ), Socket Weld (SW), Threaded (NPT, BSP), Butt Weld (BW), HUB

Body Types: 1 pc body, 2pc split body, 3pcs split body

Body&Bonnet Connection: Bolted Bonnet, Threaded Bonnet

Design Standards: API 6D, API 608, ISO 17292, BS 5351

Size Range: 1/4 - 10 Inch

Pressure Range: Class 150-2500 LB

Material Range: Cast Steel, Forged Steel, Carbon Steel, Stainless Steel, Alloy Steel, Bronze, Ti

End Connections: Flanged (FF, RF, RTJ), Socket Weld (SW), Threaded (NPT, BSP), Butt Weld (BW), HUB

Body Types: 1 pc body, 2pc split body, 3pcs split body

Body&Bonnet Connection: Bolted Bonnet, Threaded Bonnet

Showing 1–12 of 61 results

Top QUALITY Floating Ball Valves FOR YOU

A floating ball valve is versatile as there are many different choices of ball valve types available to select according to the working condition.

If you need any support with our Ball Valves, pls contact us!

Request a quote

If you need any support with our Ball Valves, pls contact us!

A floating ball valve is mainly used in the pipeline for shut-off and control applications.

It is one kind of quarter-turn valve, it's open when the ball's hole is in line with the flow inlet and closed when it is 90 degrees rotated by the valve handle, blocking the flow. And normally can be lockable at a different position to control the fluid.

It's durable, easy operation/repair and with good sealing performance even after a long time of disuse. All these advantages make it with extensive industrial use like oil&gas, chemicals, pipelines, water treatment, and mining.

A floating ball valve is versatile as there are many different choices of ball valve types available to select according to the working condition.

Main configurations:

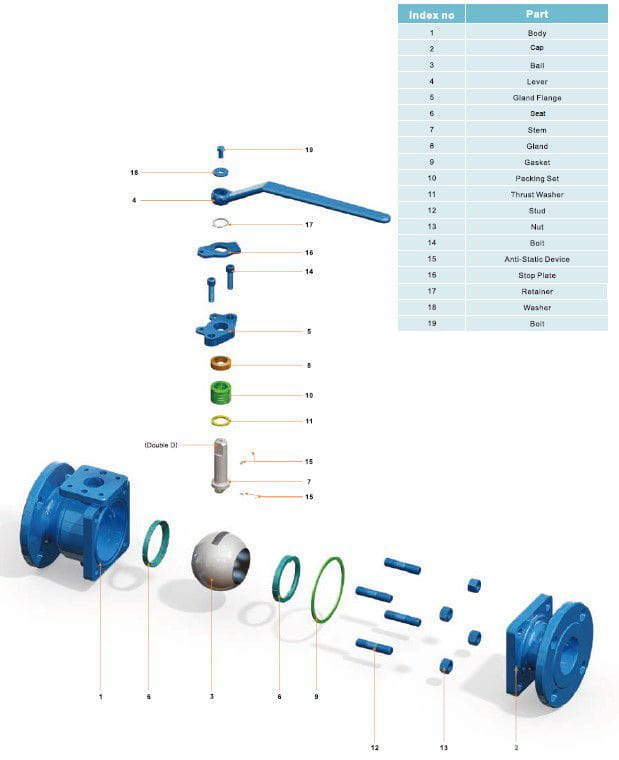

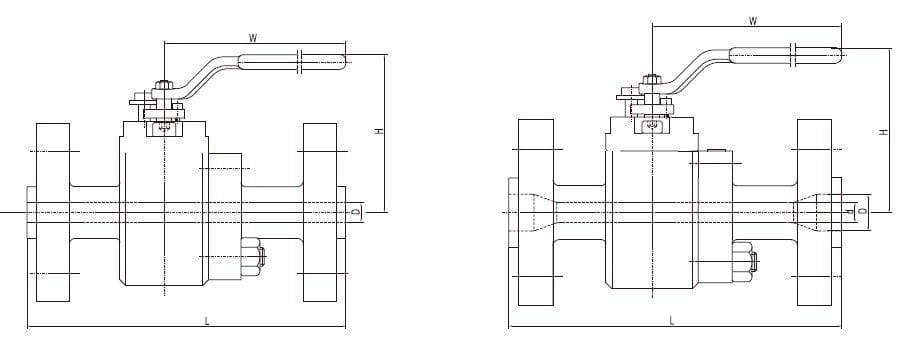

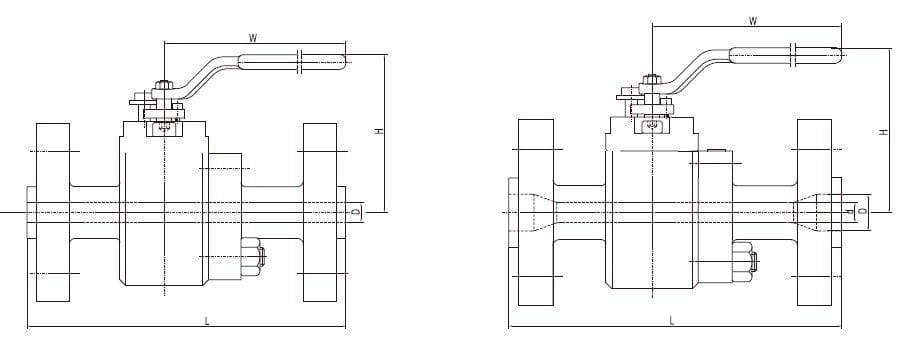

2pcs Casting Body

2pcs Forged Body

3pcs Threaded Bonnet

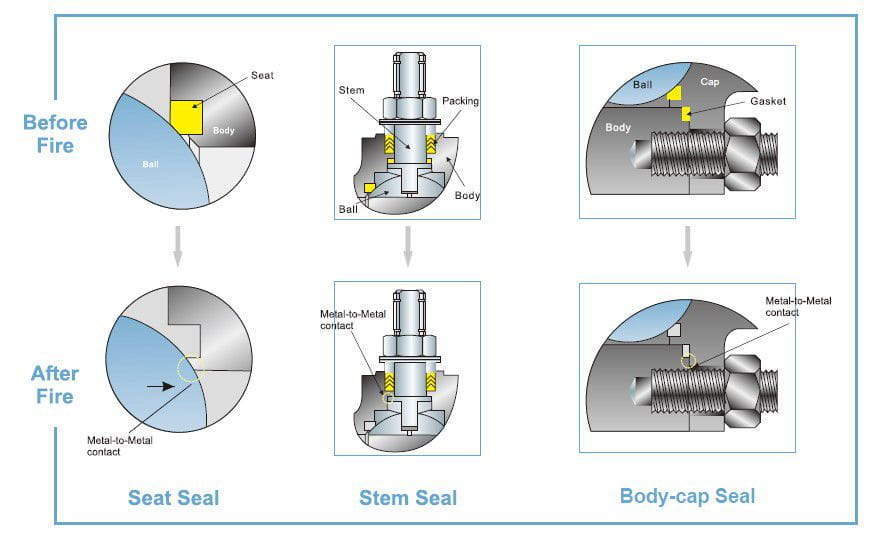

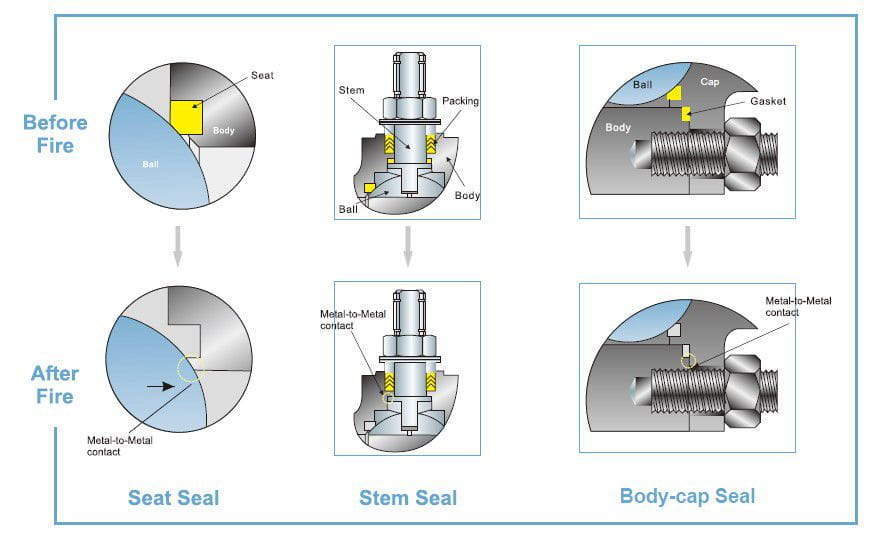

Fire Safe Standards: API 607, API 6FA, ISO 10497

Below is the fire safe design for soft seat ball valves.

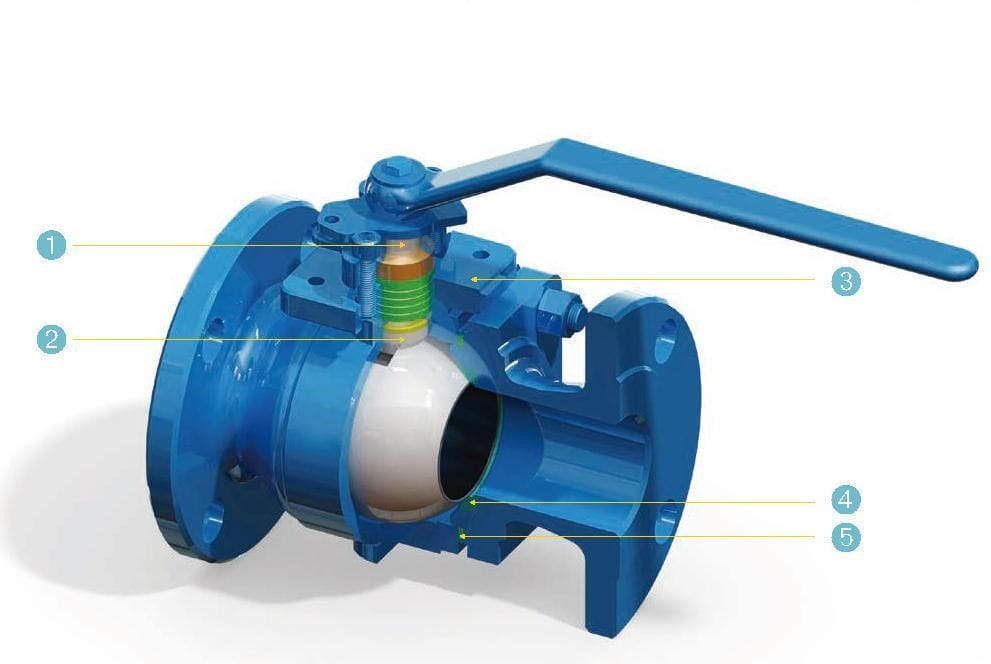

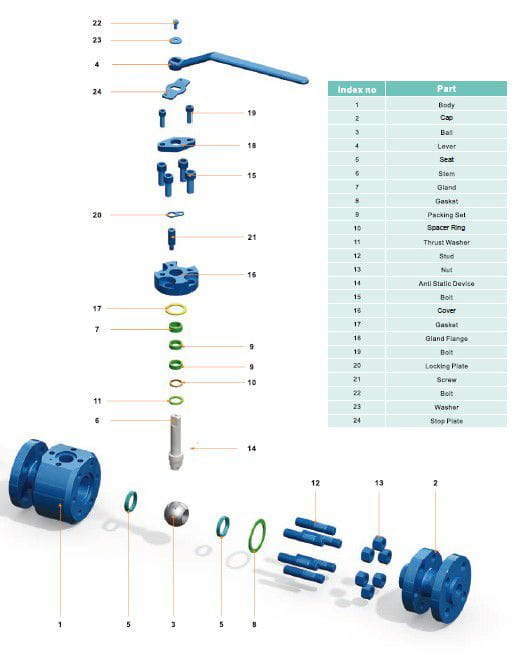

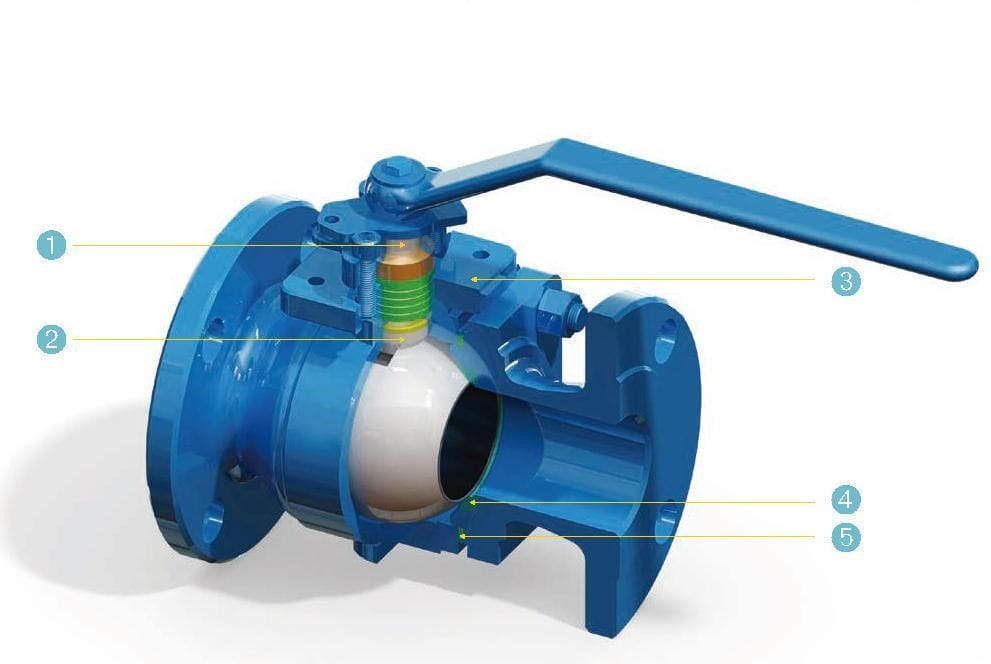

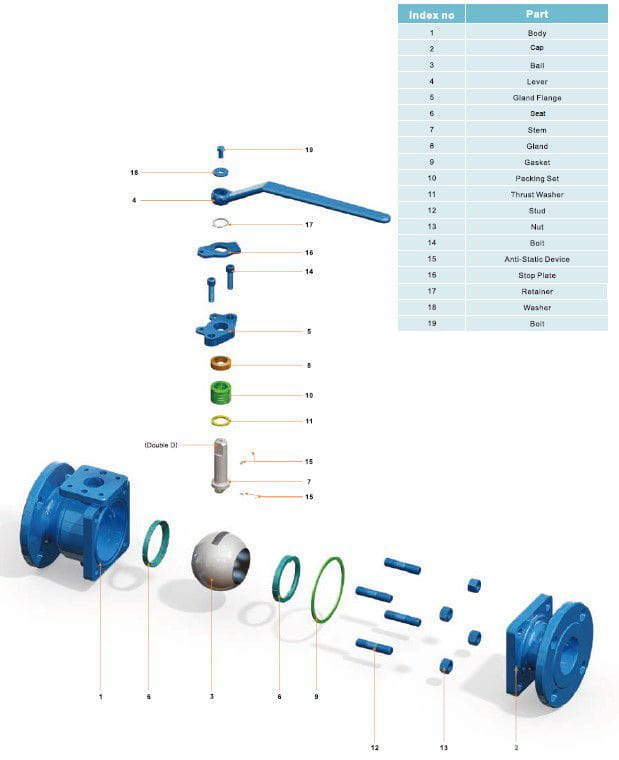

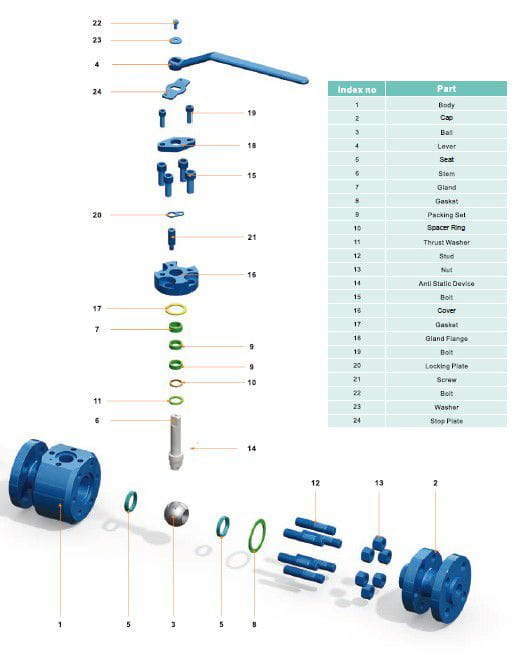

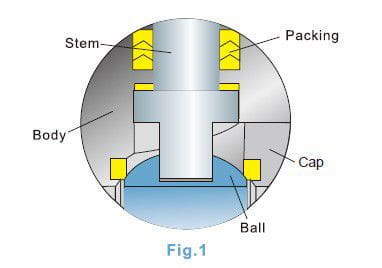

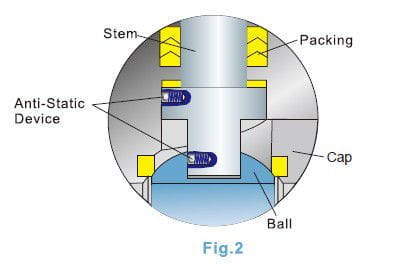

Anti-blowout Stem & Anti-static Device:

The stem is made separately from the ball. The lower end of the stem is designed with an integral shoulder to be blowout-proof.

The electrical continuity of the ball, stem, and body is ensured by the device(spring and ball) to avoid dangerous sparking during the operation.

Bore Types:

Full Bore: The hole of the ball is the same size as the pipe

Reduced Bore: The hole of the ball is with smaller size than the pipe

Seat types: Soft Seat, Metal Seat

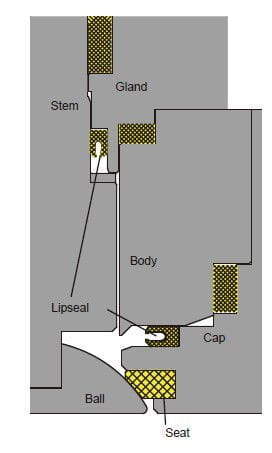

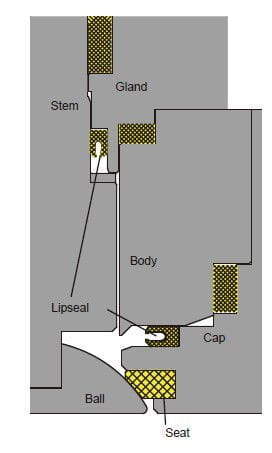

Sealing Types: O-ring, Lip Seal

Lipseal is the spring-energized seal including Elgiloy or Inconel spring and PTFE jacket. It's effective in a wide range of applications, such as high resistance to corrosive chemical media, high sour gas, low temperature or cryogenic service.

Mechanical Properties of soft seat materials

It is one kind of quarter-turn valve, it's open when the ball's hole is in line with the flow inlet and closed when it is 90 degrees rotated by the valve handle, blocking the flow. And normally can be lockable at a different position to control the fluid.

It's durable, easy operation/repair and with good sealing performance even after a long time of disuse. All these advantages make it with extensive industrial use like oil&gas, chemicals, pipelines, water treatment, and mining.

A floating ball valve is versatile as there are many different choices of ball valve types available to select according to the working condition.

Main configurations:

2pcs Casting Body

2pcs Forged Body

3pcs Threaded Bonnet

Fire Safe Standards: API 607, API 6FA, ISO 10497

Below is the fire safe design for soft seat ball valves.

Anti-blowout Stem & Anti-static Device:

The stem is made separately from the ball. The lower end of the stem is designed with an integral shoulder to be blowout-proof.

The electrical continuity of the ball, stem, and body is ensured by the device(spring and ball) to avoid dangerous sparking during the operation.

|

|

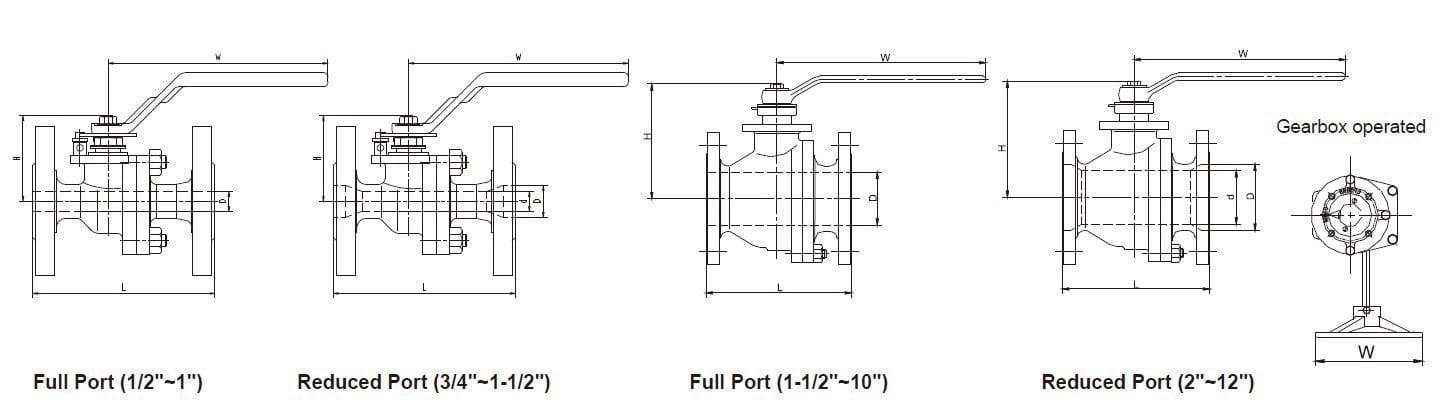

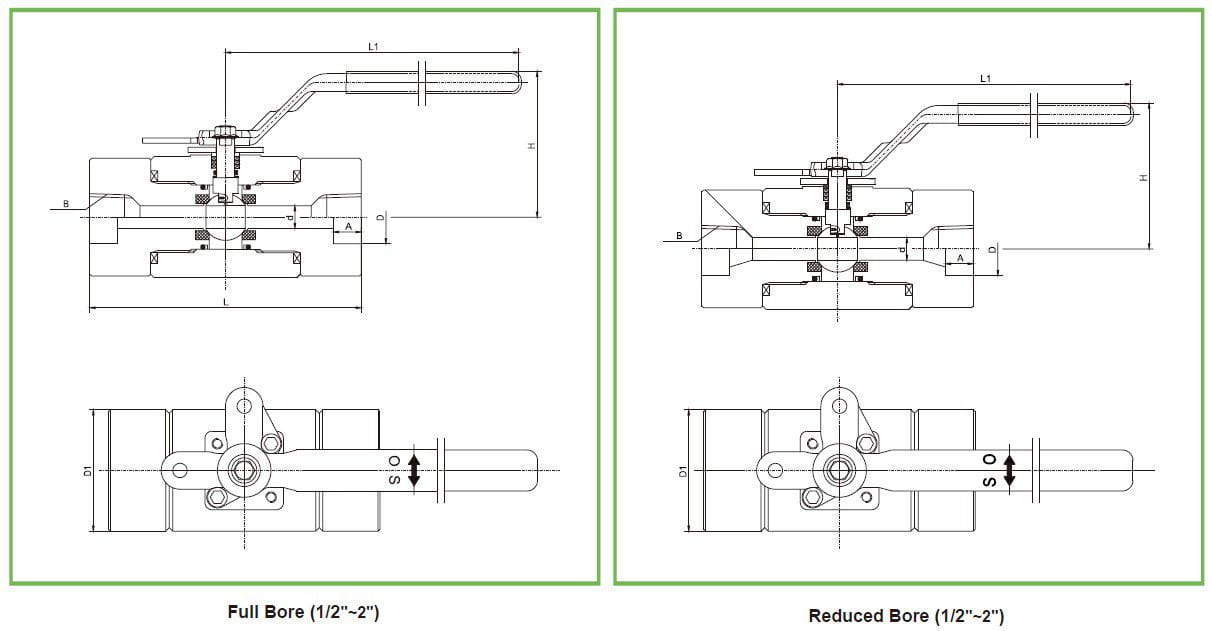

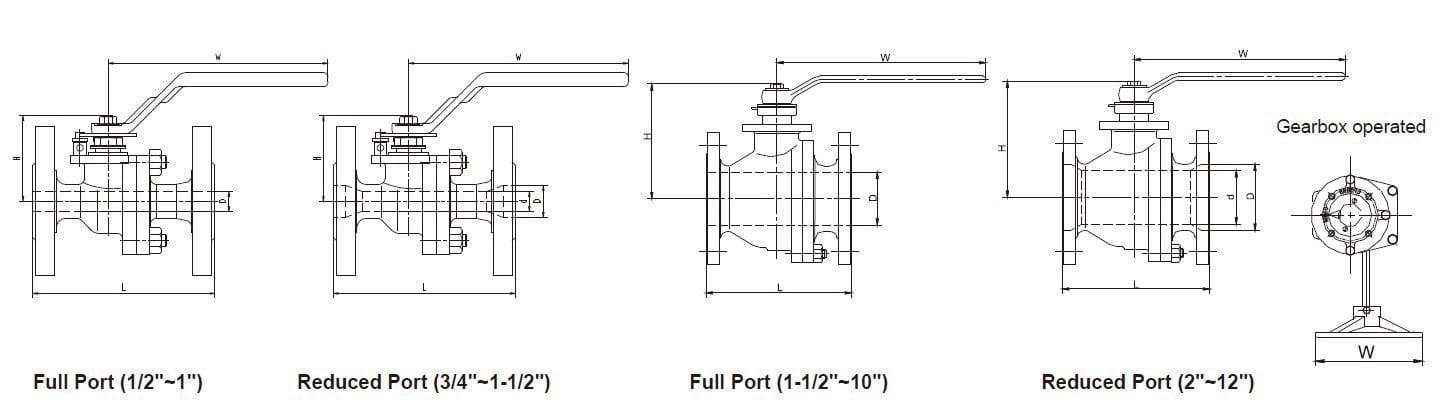

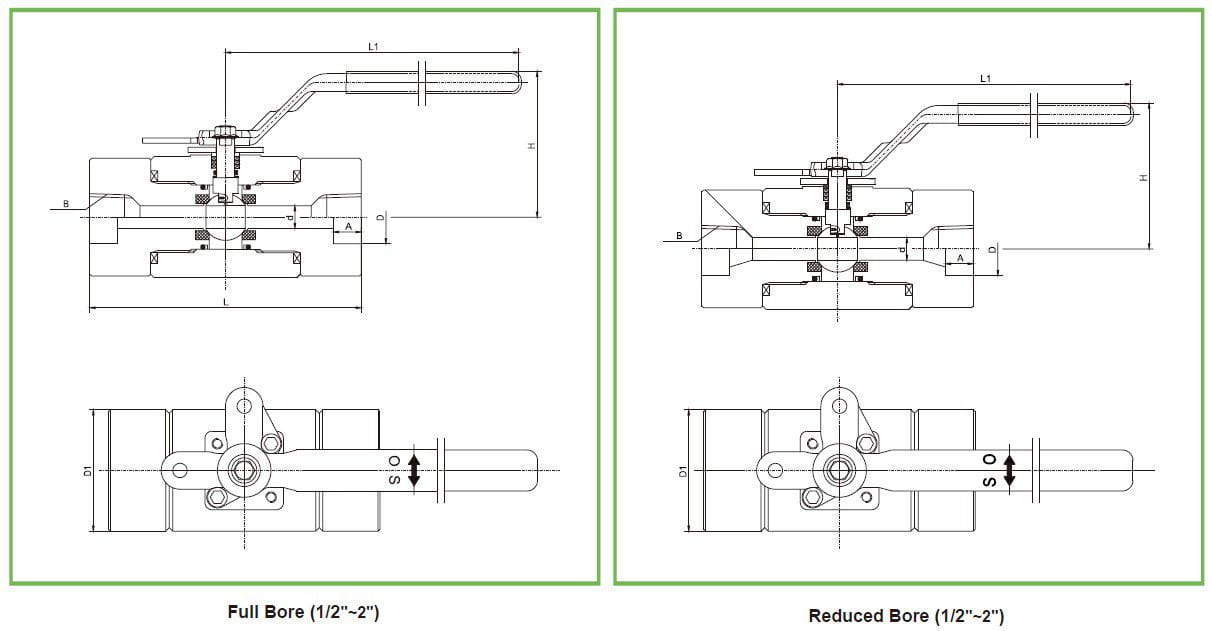

Bore Types:

Full Bore: The hole of the ball is the same size as the pipe

Reduced Bore: The hole of the ball is with smaller size than the pipe

Seat types: Soft Seat, Metal Seat

Sealing Types: O-ring, Lip Seal

Lipseal is the spring-energized seal including Elgiloy or Inconel spring and PTFE jacket. It's effective in a wide range of applications, such as high resistance to corrosive chemical media, high sour gas, low temperature or cryogenic service.

Mechanical Properties of soft seat materials

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China