Válvula de retención de pistón: ingeniería de precisión para control confiable de fluidos y protección contra reflujo

Dec 11, 2023

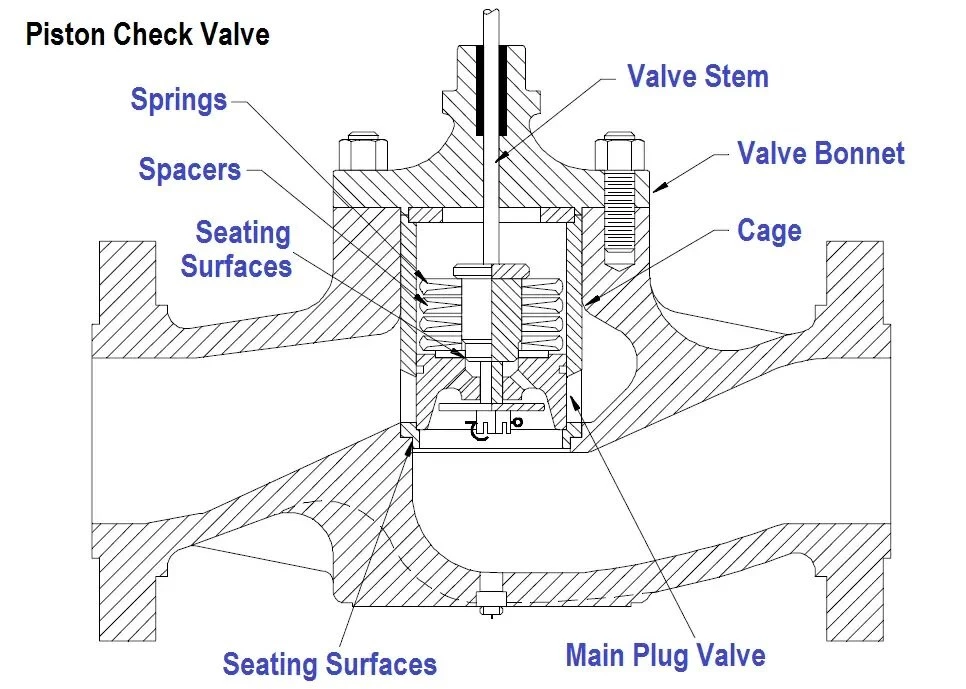

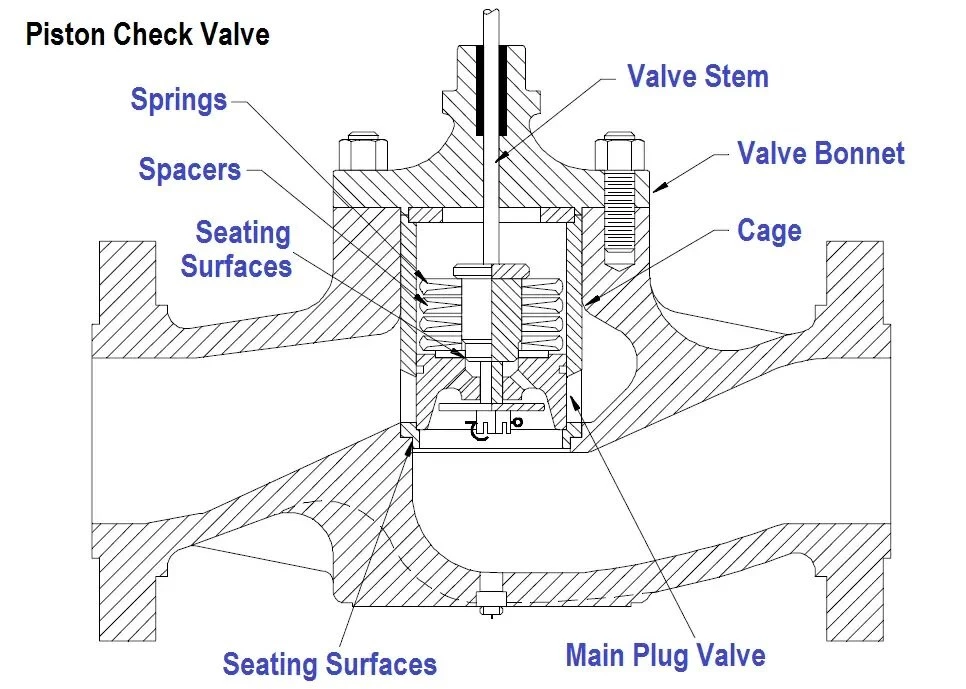

The Piston Check Valve stands out as a significant advancement in fluid control solutions, presenting a refined alternative to conventional lift check valve operations. In this exploration, we'll delve into the distinctive features, characteristics, and suggested applications that position Piston Check Valves as the preferred choice for individuals seeking precision and reliability in fluid control.

Introduction to Piston Check Valves

Piston Check Valves, similar to lift check valves, introduce an ingenious buffer system comprising a piston and cylinder. This design not only guarantees seamless operation but also functions as an efficient shock absorber, distinguishing Piston Check Valves in the realm of fluid control. The valve sets itself apart with its pioneering cushioning design, integrating a piston and cylinder to provide outstanding cushioning effects throughout its operation.

Key Features and Characteristics

Recommended Applications for Piston Check Valves

Piston Check Valves excel in pipelines with notable flow fluctuations, making them well-suited for outlet pipelines of reciprocating compressors and pumps. However, it's important to exercise caution in fluid pipelines containing sand or impurities. These valves demonstrate effectiveness in water supply, steam, and air systems, particularly in situations characterized by abrupt pressure increases and fluctuations.

Key Points for Selection and Recommendations

Superior Performance and Maintainability

The unique cushioning design of the Piston Check Valve enables continuous operation for several years, establishing it as a reliable choice for water pumps, reciprocating compressors, and similar applications. Its top-mounted design streamlines online inspection and component replacement, minimizing downtime and maximizing operational efficiency.

In summary, the Piston Check Valve redefines fluid control, offering unparalleled precision, reliability, and efficiency. Its innovative cushioning design ensures seamless operation and durability, making it a top choice for diverse applications, especially in scenarios with flow fluctuations. With a focus on longevity and easy maintenance, this valve is a standout performer in the dynamic landscape of fluid control solutions.

Introduction to Piston Check Valves

Piston Check Valves, similar to lift check valves, introduce an ingenious buffer system comprising a piston and cylinder. This design not only guarantees seamless operation but also functions as an efficient shock absorber, distinguishing Piston Check Valves in the realm of fluid control. The valve sets itself apart with its pioneering cushioning design, integrating a piston and cylinder to provide outstanding cushioning effects throughout its operation.

Key Features and Characteristics

- Soft and Hard Sealing Options: Providing flexibility by offering a choice between soft and hard sealing, meeting a wide range of operational needs.

- Replaceable Valve Seat: Improving valve longevity and maintainability through a replaceable valve seat, minimizing downtime and operational interruptions.

- Variety of Material Options: Adapting to diverse mediums and conditions with a selection of body and internal material options.

- Enhanced Seal with Higher Back Pressure: Ensuring superior sealing performance even under increased back pressure, optimizing overall efficiency.

- Versatile Installation Methods: Typically suitable for horizontal installation; manufacturer consultation is advised for vertical setups.

Recommended Applications for Piston Check Valves

Piston Check Valves excel in pipelines with notable flow fluctuations, making them well-suited for outlet pipelines of reciprocating compressors and pumps. However, it's important to exercise caution in fluid pipelines containing sand or impurities. These valves demonstrate effectiveness in water supply, steam, and air systems, particularly in situations characterized by abrupt pressure increases and fluctuations.

Key Points for Selection and Recommendations

1. Operating Conditions Communication: Clearly articulate operating conditions when ordering to align with specific medium requirements within a defined range.

2. Orifice Plate Sizing: In liquid and gas pipeline designs, ensure that orifice plates for liquids are notably larger than those for gases.

3. Medium Suitability: Piston Check Valves designed for gas pipeline conditions may not be suitable for liquid operations unless the orifice plate in the piston is replaced to match the medium.

4. Pipeline Design Considerations: Consider the overall design of the pipeline, especially in situations with significant flow fluctuations.

5. Compatibility: Assess compatibility with other valves in the pipeline system, especially when used alongside globe valves and angle valves.

2. Orifice Plate Sizing: In liquid and gas pipeline designs, ensure that orifice plates for liquids are notably larger than those for gases.

3. Medium Suitability: Piston Check Valves designed for gas pipeline conditions may not be suitable for liquid operations unless the orifice plate in the piston is replaced to match the medium.

4. Pipeline Design Considerations: Consider the overall design of the pipeline, especially in situations with significant flow fluctuations.

5. Compatibility: Assess compatibility with other valves in the pipeline system, especially when used alongside globe valves and angle valves.

Superior Performance and Maintainability

The unique cushioning design of the Piston Check Valve enables continuous operation for several years, establishing it as a reliable choice for water pumps, reciprocating compressors, and similar applications. Its top-mounted design streamlines online inspection and component replacement, minimizing downtime and maximizing operational efficiency.

In summary, the Piston Check Valve redefines fluid control, offering unparalleled precision, reliability, and efficiency. Its innovative cushioning design ensures seamless operation and durability, making it a top choice for diverse applications, especially in scenarios with flow fluctuations. With a focus on longevity and easy maintenance, this valve is a standout performer in the dynamic landscape of fluid control solutions.

Siguiente: Válvula de mariposa de doble polarización y selección de válvula de mariposa de tres polarización

Anterior: Válvula de bola de montaje de muñón: avance en la tecnología de válvula de alto rendimiento

Sobre nosotros

Categorías

Enlaces útiles

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China