Guía de reparación de reemplazo de sello de válvula de bola neumática

Mar 05, 2024

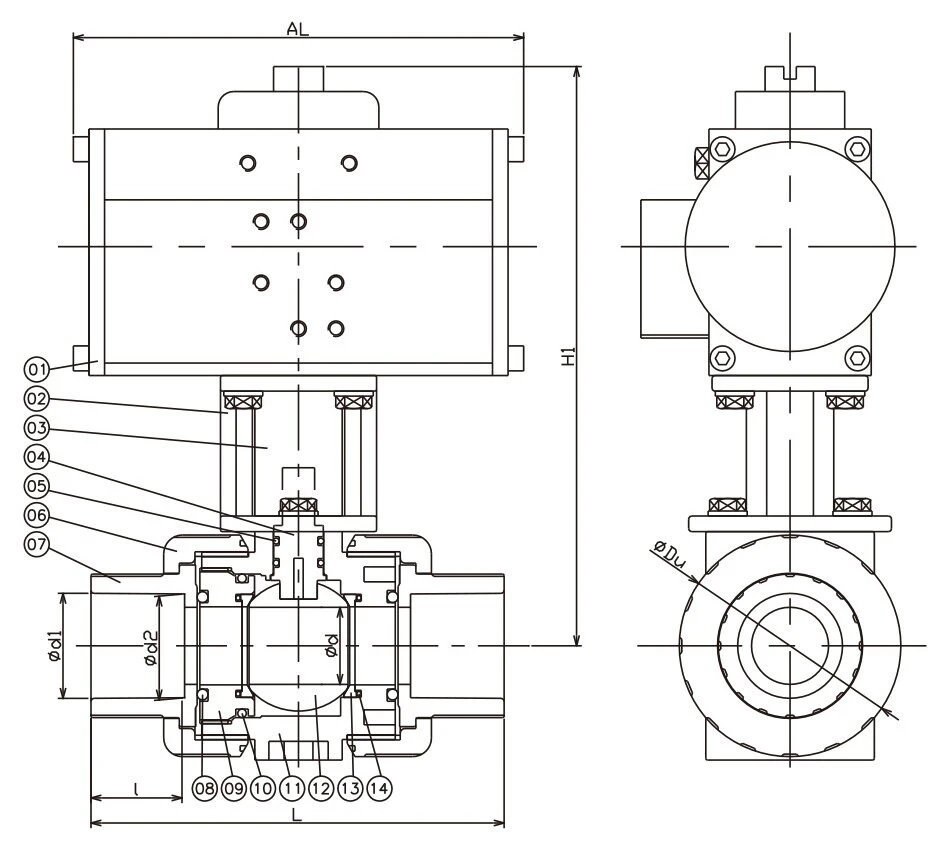

Pneumatic ball valves are common critical control devices in industrial settings, where their reliability is closely tied to the condition of the sealing rings. However, with prolonged operation and exposure to various media, sealing rings inevitably undergo aging and wear, affecting the normal operation of the ball valve. To ensure system stability and safety, timely replacement of sealing rings is essential. Below is a detailed maintenance guide to facilitate the smooth replacement of sealing rings.

1. Stop Air Supply and Disconnect Relevant Pipelines

Before conducting any maintenance work, ensure to shut off the pneumatic ball valve and the compressed air supply completely. Then, disconnect the compressed air connection pipe from the solenoid valve to the cylinder to facilitate subsequent operations.

2. Disassemble Cylinder End Cap and Cylinder Barrel

Loosen the cylinder tightening bolts using appropriate tools and gently tap the cylinder end cap of the pneumatic ball valve to remove it. Inside the end cap, the sealing rings needing replacement are usually located. Subsequently, slowly open the pneumatic valve using the manual operation lever to move the cylinder piston to one end of the cylinder seat. Gently tap the cylinder barrel and remove it.

3. Inspect Cylinder Barrel and Piston Rod

Thoroughly inspect the inner wall of the cylinder barrel for corrosion or wear. If minor corrosion is observed, use emery paper to polish and apply rust-proof oil. If severe corrosion is detected, the cylinder barrel must be replaced. Additionally, check the condition of the piston rod for wear or corrosion and address or replace it accordingly.

4. Replace Sealing Rings

Carefully inspect the sealing rings at various parts of the pneumatic ball valve, and promptly replace any rings showing signs of aging or wear. Before replacing the sealing rings, ensure cleanliness and apply a layer of Vaseline for ease of installation, selecting the appropriate sealing ring specifications.

5. Overhaul Rotary Mechanism and Reassemble

Check the rotary mechanism for signs of wear and ensure proper lubrication. Apply lubricating grease if necessary. Then, reassemble the cylinder barrel, cylinder end cap, and tightening bolts in reverse order, ensuring each step is performed accurately.

6. System Testing and Debugging

Reconnect the compressed air connection pipe from the solenoid valve to the cylinder and gradually open the compressed air supply valve. Use the manual operation lever to slowly close the pneumatic valve, causing the cylinder piston to return to one end of the cylinder end cap. Perform an open-close test of the pneumatic ball valve to ensure smooth operation without sticking, and check for any air leaks from the cylinder.

7. System Recovery and Documentation

After completing the operation, ensure that all components are restored to their original state and record any replaced parts. Monitor the system's operation and conduct regular inspections to ensure its stability and safety.

Before conducting any maintenance work, ensure to shut off the pneumatic ball valve and the compressed air supply completely. Then, disconnect the compressed air connection pipe from the solenoid valve to the cylinder to facilitate subsequent operations.

2. Disassemble Cylinder End Cap and Cylinder Barrel

Loosen the cylinder tightening bolts using appropriate tools and gently tap the cylinder end cap of the pneumatic ball valve to remove it. Inside the end cap, the sealing rings needing replacement are usually located. Subsequently, slowly open the pneumatic valve using the manual operation lever to move the cylinder piston to one end of the cylinder seat. Gently tap the cylinder barrel and remove it.

3. Inspect Cylinder Barrel and Piston Rod

Thoroughly inspect the inner wall of the cylinder barrel for corrosion or wear. If minor corrosion is observed, use emery paper to polish and apply rust-proof oil. If severe corrosion is detected, the cylinder barrel must be replaced. Additionally, check the condition of the piston rod for wear or corrosion and address or replace it accordingly.

4. Replace Sealing Rings

Carefully inspect the sealing rings at various parts of the pneumatic ball valve, and promptly replace any rings showing signs of aging or wear. Before replacing the sealing rings, ensure cleanliness and apply a layer of Vaseline for ease of installation, selecting the appropriate sealing ring specifications.

5. Overhaul Rotary Mechanism and Reassemble

Check the rotary mechanism for signs of wear and ensure proper lubrication. Apply lubricating grease if necessary. Then, reassemble the cylinder barrel, cylinder end cap, and tightening bolts in reverse order, ensuring each step is performed accurately.

6. System Testing and Debugging

Reconnect the compressed air connection pipe from the solenoid valve to the cylinder and gradually open the compressed air supply valve. Use the manual operation lever to slowly close the pneumatic valve, causing the cylinder piston to return to one end of the cylinder end cap. Perform an open-close test of the pneumatic ball valve to ensure smooth operation without sticking, and check for any air leaks from the cylinder.

7. System Recovery and Documentation

After completing the operation, ensure that all components are restored to their original state and record any replaced parts. Monitor the system's operation and conduct regular inspections to ensure its stability and safety.

Through the above maintenance guide, we can promptly and effectively replace the sealing rings of pneumatic ball valves, prolonging their service life and ensuring the stability of system operation. This not only enhances equipment reliability but also guarantees the continuity and safety of production processes. Regular inspection and maintenance of pneumatic ball valves are crucial for ensuring the smooth operation of industrial systems.

Siguiente: La importancia de la válvula de cierre de ángulo en la producción industrial

Anterior: Sistema de tuberías para suspender la configuración y coordinación de la válvula de retorno

Sobre nosotros

Categorías

Enlaces útiles

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China