La causa raíz de la fuga de la válvula de compuerta y su solución

Feb 23, 2024

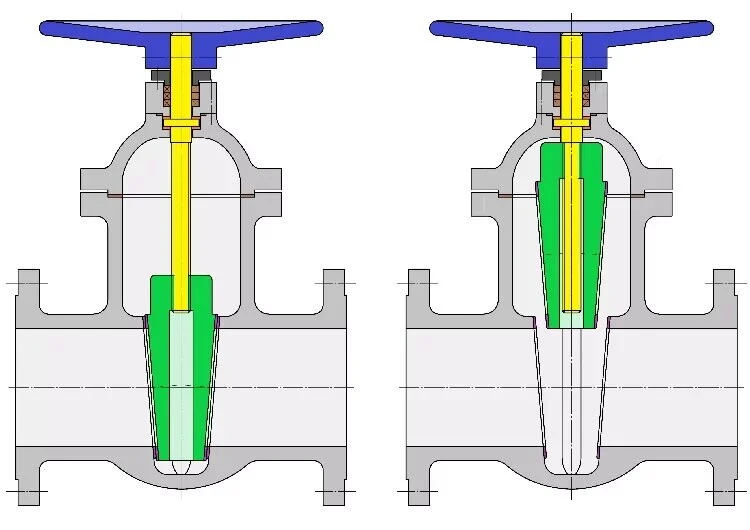

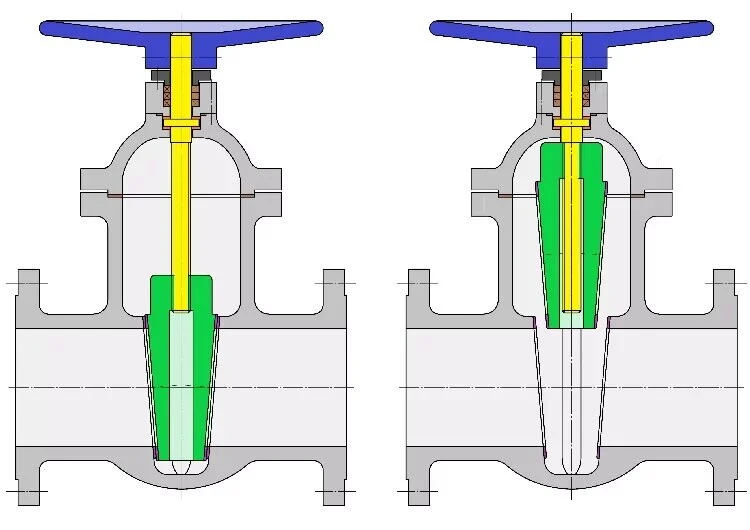

Gate valves, as one of the widely used industrial valves, play a crucial role in various engineering applications. However, due to their complex structure and unique operational environments, gate valve leakage issues are not uncommon, posing certain risks to industrial production. To gain a comprehensive understanding of gate valve leakage problems and effectively address them, it is necessary to delve into their root causes while exploring multiple handling solutions.

Root Causes of Gate Valve Leakage

Gate valve leakage can occur due to various reasons, and understanding the root causes is essential for effective troubleshooting and maintenance. Here are some common factors that can contribute to gate valve leakage:

Diversified Solutions for Gate Valve Leakage

Addressing the root causes of gate valve leakage involves implementing diversified solutions that target specific issues. Here are solutions corresponding to the identified root causes:

Through in-depth analysis of gate valve leakage issues and exploration of diversified handling solutions, we can better understand the root causes of leakage problems and take targeted measures to address them. In future work, emphasis should be placed on preventive maintenance, with regular inspections and maintenance of gate valve equipment to ensure its safe and stable operation, thereby providing assurance for smooth industrial production.

Root Causes of Gate Valve Leakage

Gate valve leakage can occur due to various reasons, and understanding the root causes is essential for effective troubleshooting and maintenance. Here are some common factors that can contribute to gate valve leakage:

- Precision Issues in Sealing Ring Manufacturing: The precision of both hard and soft wedge sealing rings directly affects the sealing performance of the valve. Insufficient precision in manufacturing can lead to leakage.

- Unstable Production Conditions: Variations in pressure and temperature during valve production processes can impact the sealing performance of the valve. Unstable operational conditions may result in uneven stress on the sealing ring, leading to leakage.

- Substandard Maintenance Practices: During maintenance, failure to thoroughly clean the sealing surface or negligence in installing the sealing ring can cause leakage.

- Corrosion from Medium: Corrosive mediums can damage the surface of the sealing ring, affecting its sealing effectiveness and causing leakage.

- Actuator Misalignment: Malfunction or improper operation of actuators may prevent the valve from fully closing, thus resulting in leakage.

- Valve Body Defects: Defects such as pores, inclusions, or cracks in the valve body casting may serve as potential sources of leakage.

Diversified Solutions for Gate Valve Leakage

Addressing the root causes of gate valve leakage involves implementing diversified solutions that target specific issues. Here are solutions corresponding to the identified root causes:

1. Strengthening Valve Body & Bolts: Tightening bolts and increasing pre-tightening force can reduce the gap between the sealing ring and the valve body, thereby minimizing leakage.

2. Sealant Injection for Minor Leaks: For minor internal leaks, injecting sealant can provide a temporary solution to alleviate the leakage problem.

3. Welding Reinforcement: Defects in valve body surfaces, filler boxes, and pressure plates can be repaired by welding reinforcement to ensure the integrity of the valve.

4. Actuator Position Verification: Regularly inspecting and adjusting the zero position of actuators ensures that the valve can fully close, preventing leakage due to actuator failure.

5. Welding Repair or Factory Maintenance: For severe valve body defects, welding repair or replacement by returning to the factory ensures the reliability and safety of the valve.

2. Sealant Injection for Minor Leaks: For minor internal leaks, injecting sealant can provide a temporary solution to alleviate the leakage problem.

3. Welding Reinforcement: Defects in valve body surfaces, filler boxes, and pressure plates can be repaired by welding reinforcement to ensure the integrity of the valve.

4. Actuator Position Verification: Regularly inspecting and adjusting the zero position of actuators ensures that the valve can fully close, preventing leakage due to actuator failure.

5. Welding Repair or Factory Maintenance: For severe valve body defects, welding repair or replacement by returning to the factory ensures the reliability and safety of the valve.

Through in-depth analysis of gate valve leakage issues and exploration of diversified handling solutions, we can better understand the root causes of leakage problems and take targeted measures to address them. In future work, emphasis should be placed on preventive maintenance, with regular inspections and maintenance of gate valve equipment to ensure its safe and stable operation, thereby providing assurance for smooth industrial production.

Anterior: Transformación de dureza entre HRC, HB y HV

Sobre nosotros

Categorías

Enlaces útiles

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China