Dual Plate Check Valve

- Home/

- Products/

- Check Valves/

- Dual Plate Check Valve

With years of experience as a dual plate check valve manufacturer in China, we have a strong reputation in the industry.

Valve Types: Dual Plate Check Valve, Single Plate Wafer Check Valve, Thin Type WAFER Check Valve, Lifting Wafer Check Valve

Seat Type: Soft Seat, Metal Seat

Design Standards: API 594, API 6D

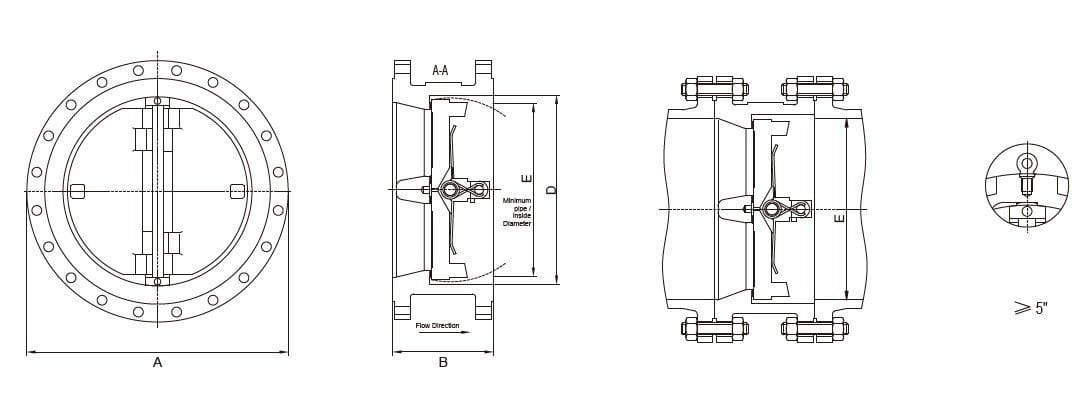

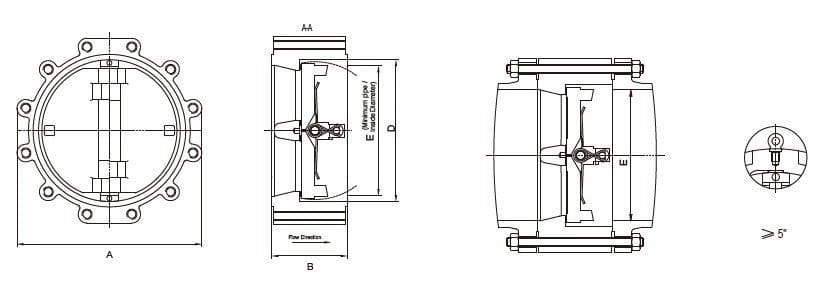

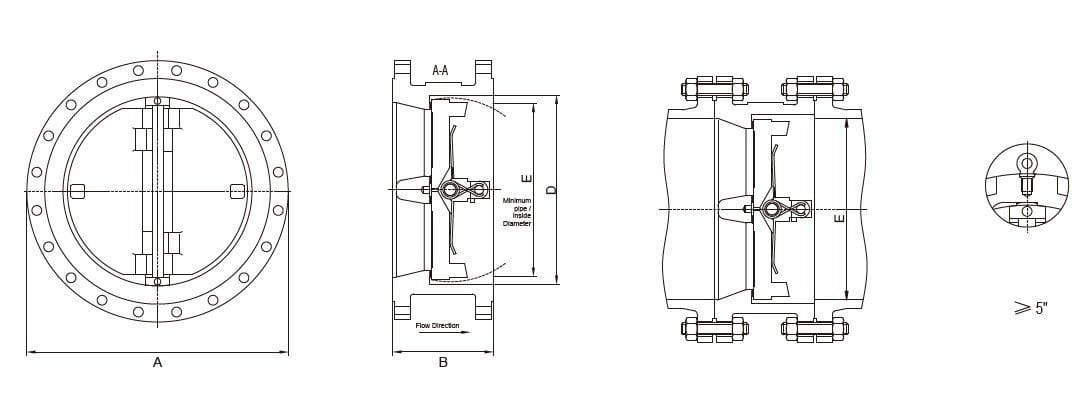

Size Range: 2-64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ), Butt Weld (BW), HUB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Valve Types: Dual Plate Check Valve, Single Plate Wafer Check Valve, Thin Type WAFER Check Valve, Lifting Wafer Check Valve

Seat Type: Soft Seat, Metal Seat

Design Standards: API 594, API 6D

Size Range: 2-64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ), Butt Weld (BW), HUB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Showing 1–12 of 100 results

MOST QUALITY Dual Plate Check Valves FOR YOU

Attentions:

The dual Plate Check Valve is not a shut-off valve.

The dual Plate Check Valve is not pingable.

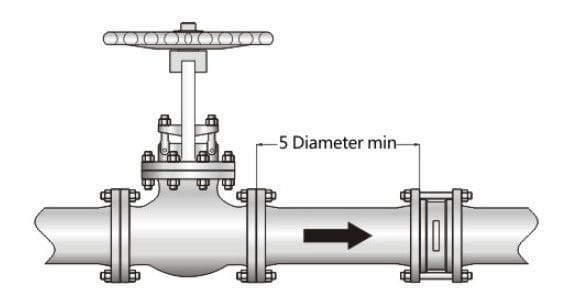

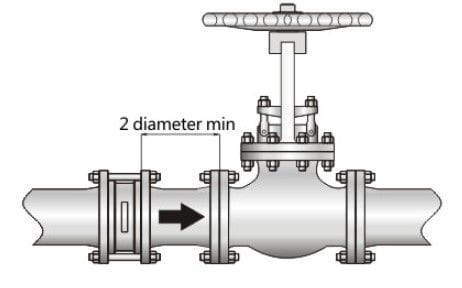

When it’s used, a shut-off valve shall always be installed together

If you need any support with our Ball Valves, pls contact us!

Request a quote

The dual Plate Check Valve is not a shut-off valve.

The dual Plate Check Valve is not pingable.

When it’s used, a shut-off valve shall always be installed together

If you need any support with our Ball Valves, pls contact us!

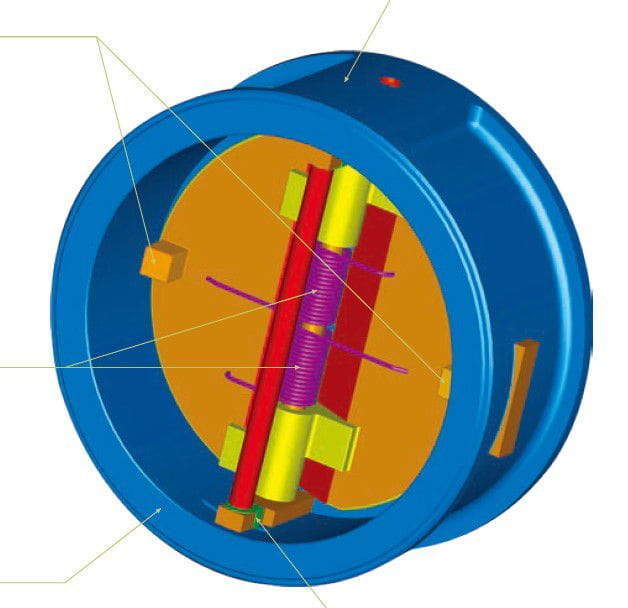

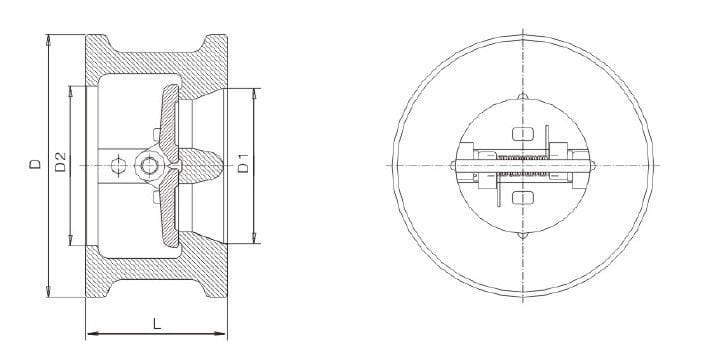

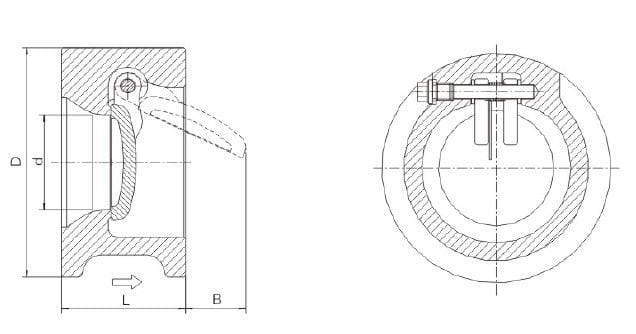

The dual Plate Check valve is a spring-loaded non-return valve. It’s basically a one-way valve and is generally used in pipelines to prevent backflow.

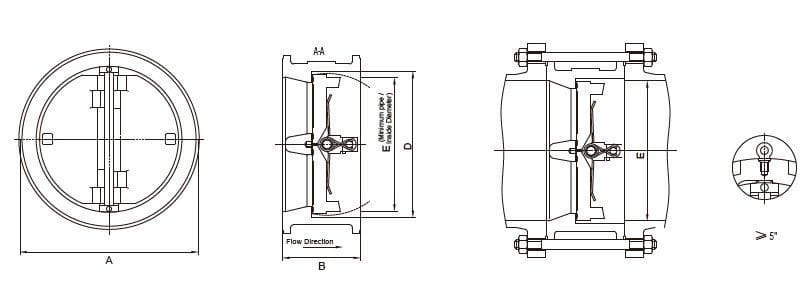

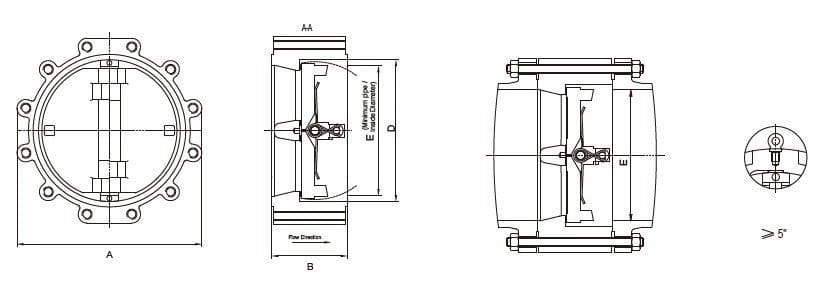

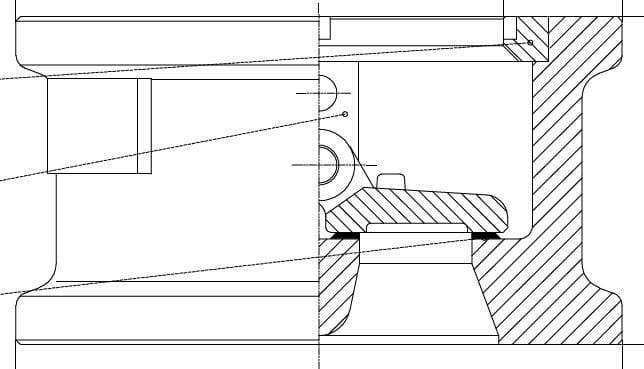

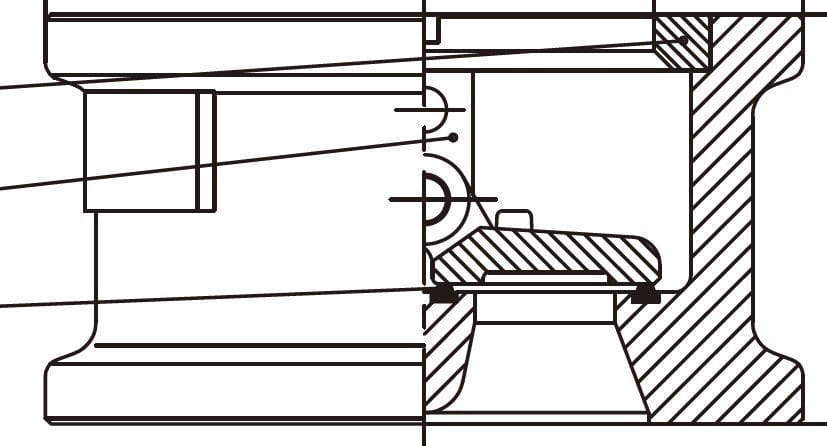

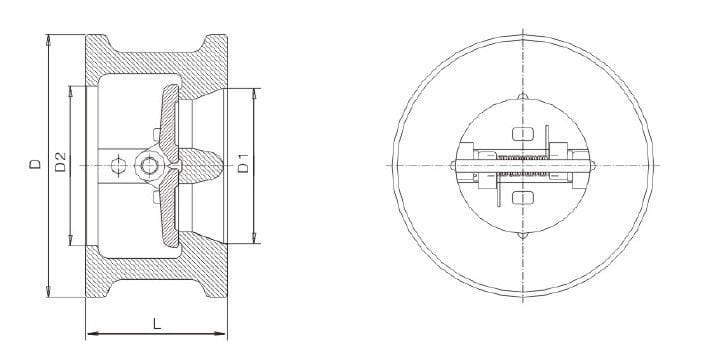

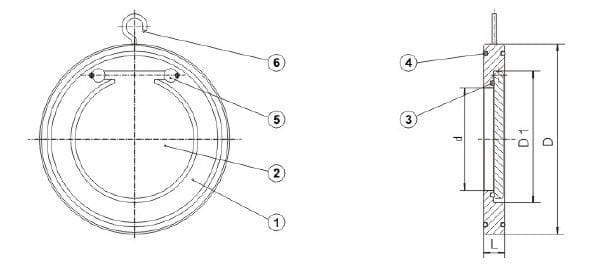

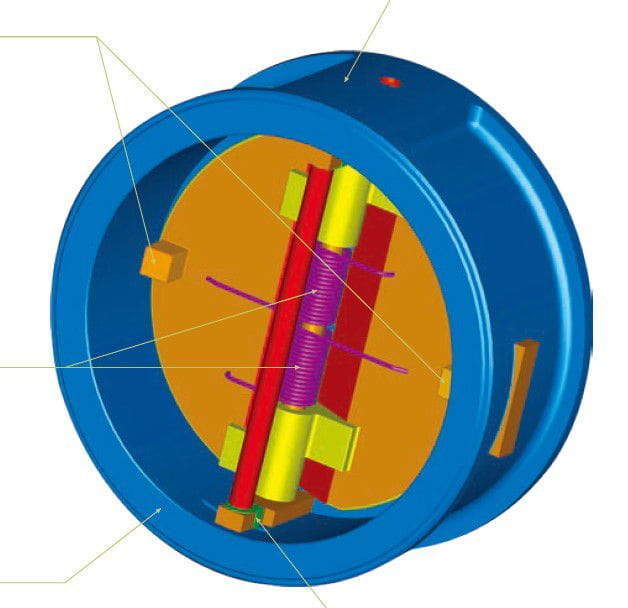

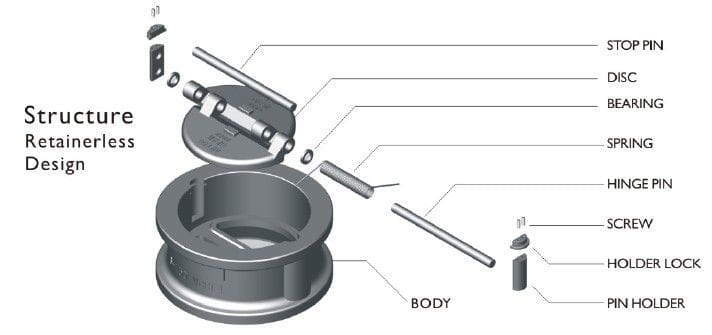

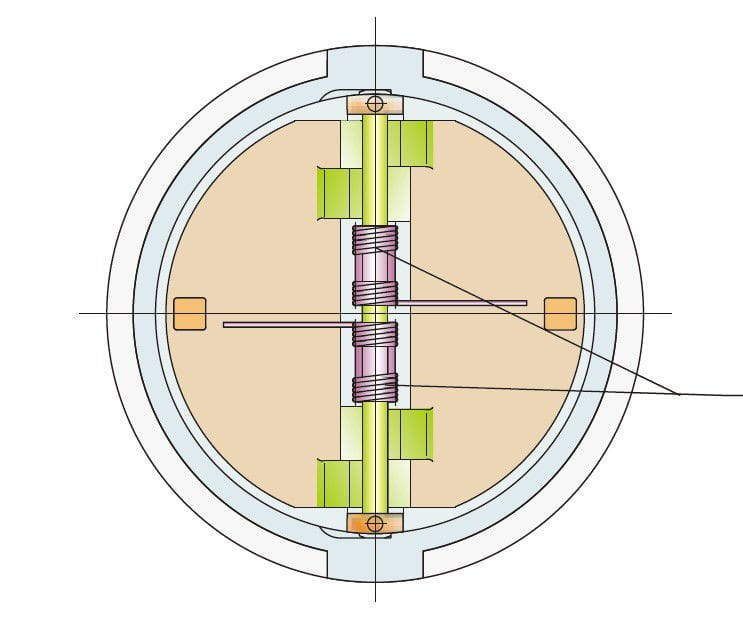

It’s made of a one-piece body, a pin at the centerline and two plates fixed by the pin and loaded with spring, it allows fluid to pass through in the flow direction and block the fluid when the flow return.

Compared with conventional swing check valves it can significantly reduce the weight and length and it results in saving cost and space of the piping system.

Compact Design

The weight is only around 20% of the equivalent swing check valve.

Swing Check Valve VS Dual Plate Check Valve

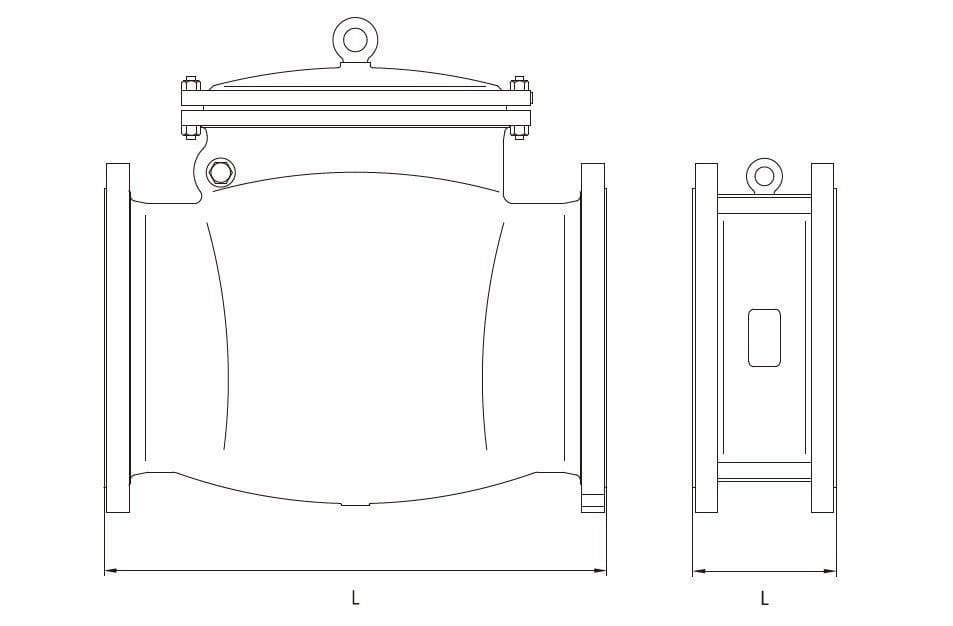

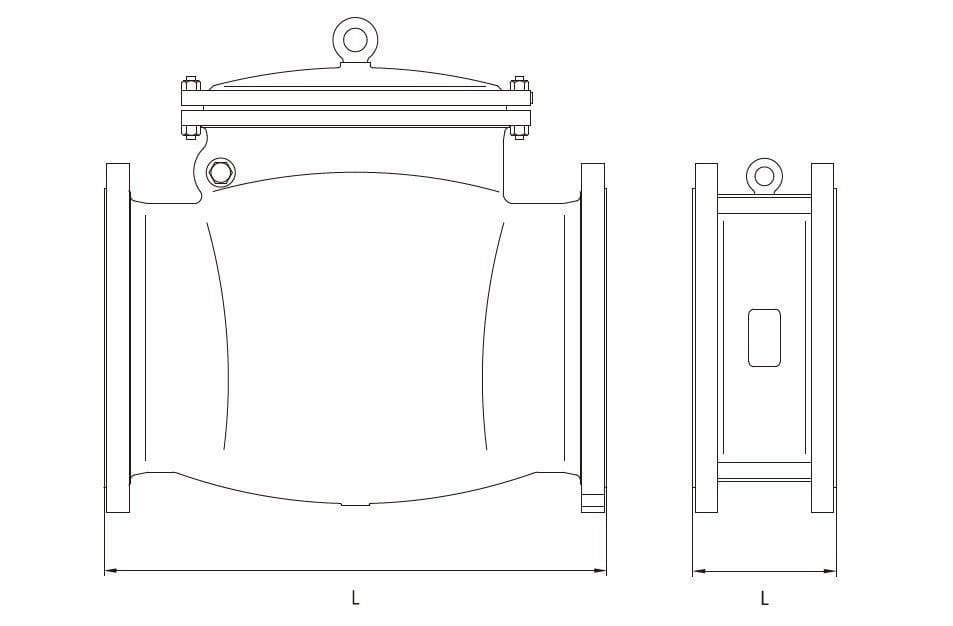

End Connections

Wafer End

Lug End

Flanged End

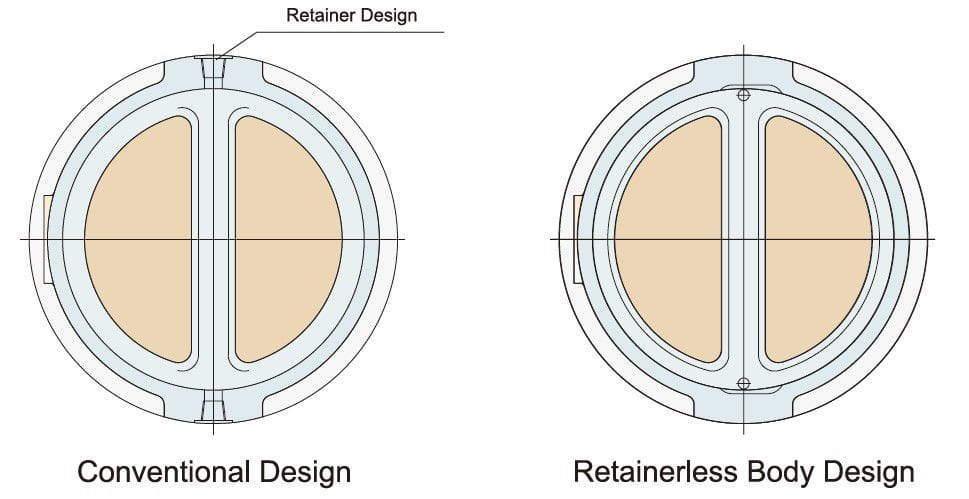

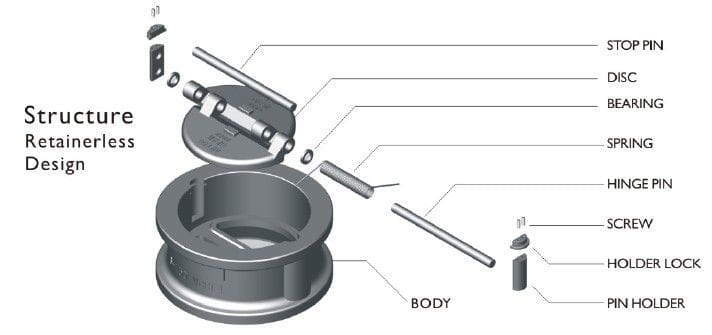

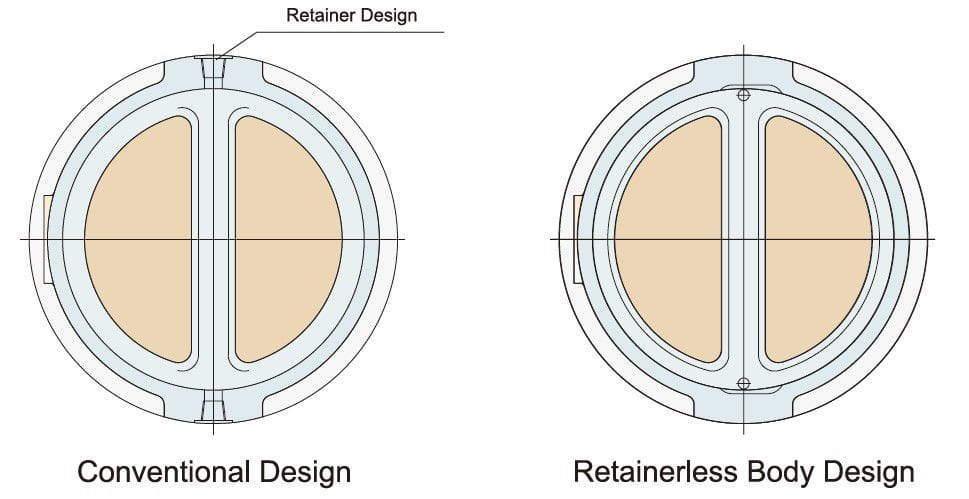

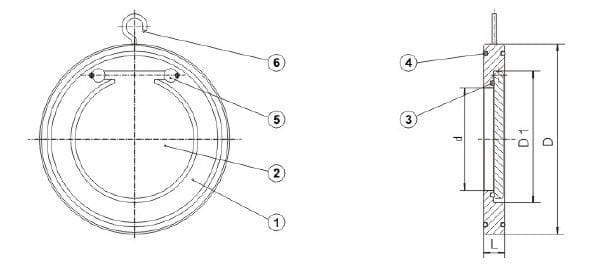

Retainerless Body

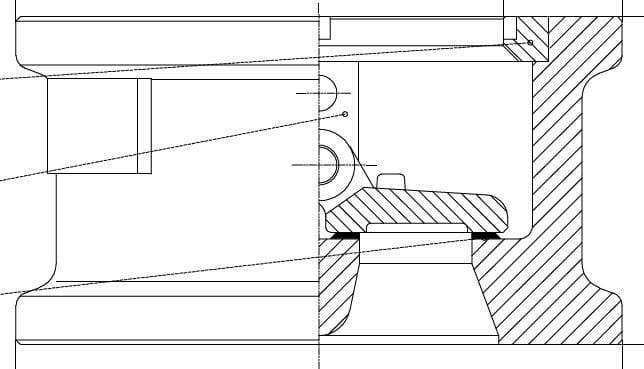

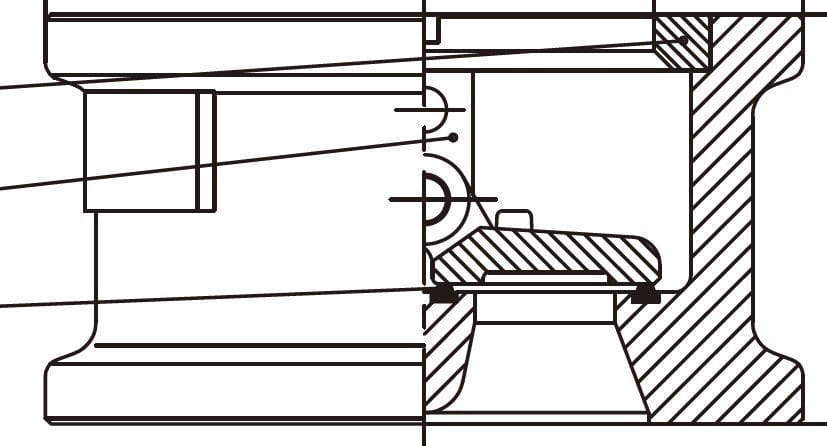

The bosseal dual plate valve is a one-piece design without a hole through the body, there are no external pins to retain the disc/stem, so that no external leakage point, it's a good choice for critical service.

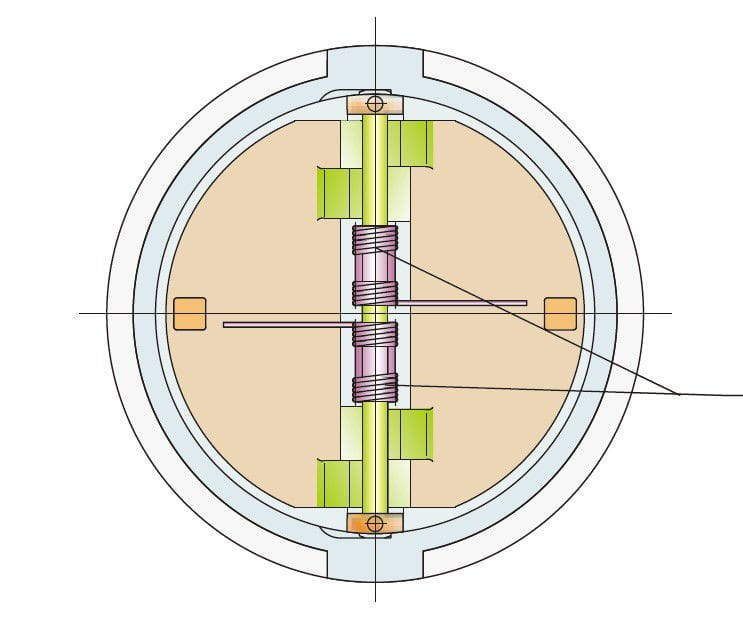

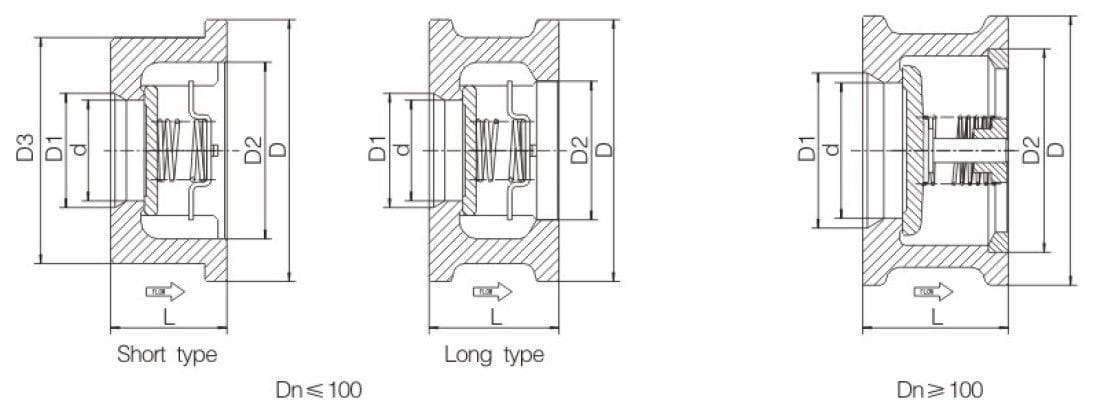

Independent Spring

The two plates are actuated by two separate high torsion springs and it ensures a quick closing, lower water hammer affection, longer working life and better sealing performance.

Optional Soft and Metal Seat

Metal Seat: STL (CoCr alloy) overlay on the body seat, suitable for high temperature

Soft Seat: Viton, EPDM, NBR, PTFE (not recommended)

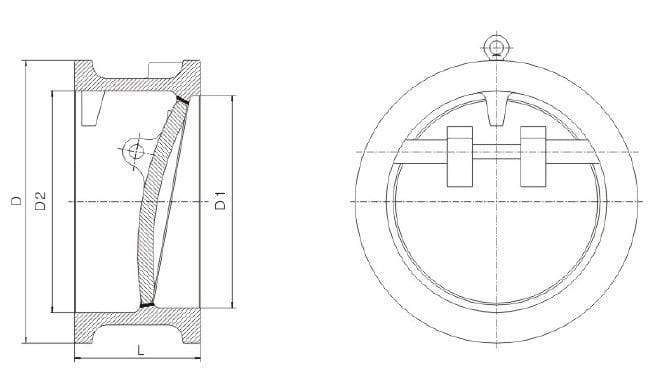

Unique Slim Plate Design

The plate size and shape are well designed to have lightweight, good flow efficiency, low-pressure loss, fast operation and better sealing performance under low pressure.

Other Wafer Check Valve Types are Available

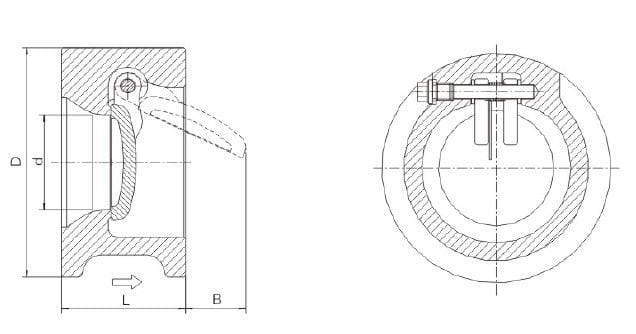

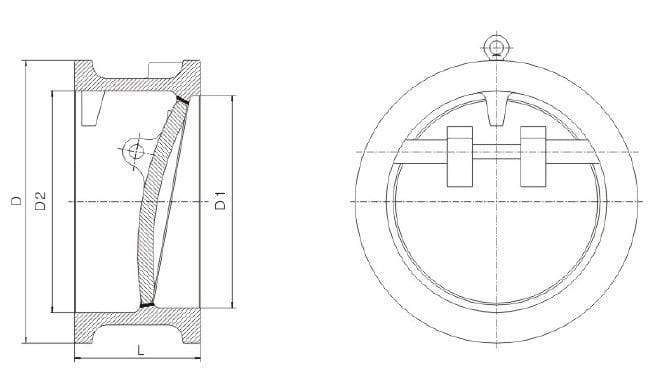

Single Plate Wafer Check Valve

Thin Type Wafer Check Valve

Titling Disc Wafer Check Valve

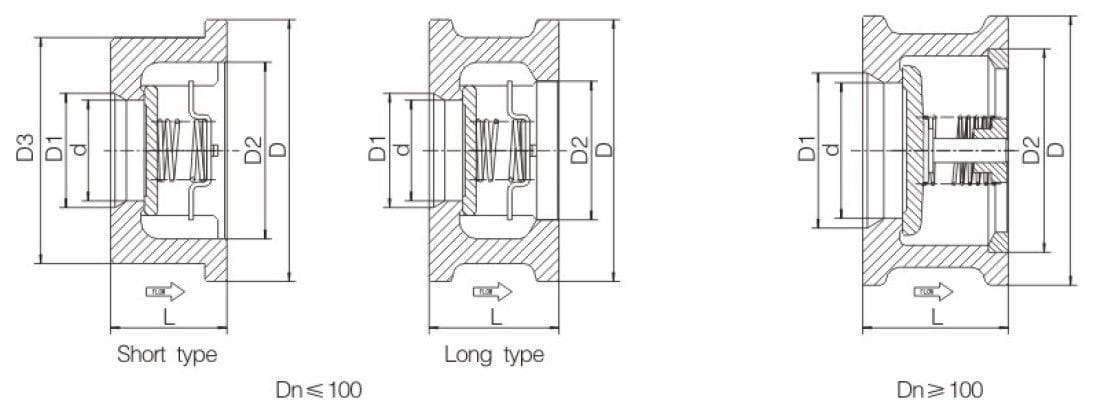

Piston Type (Lifting) Wafer Check Valve

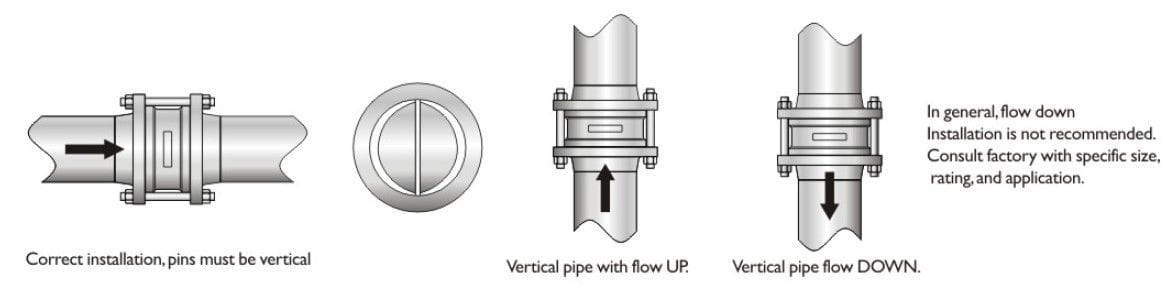

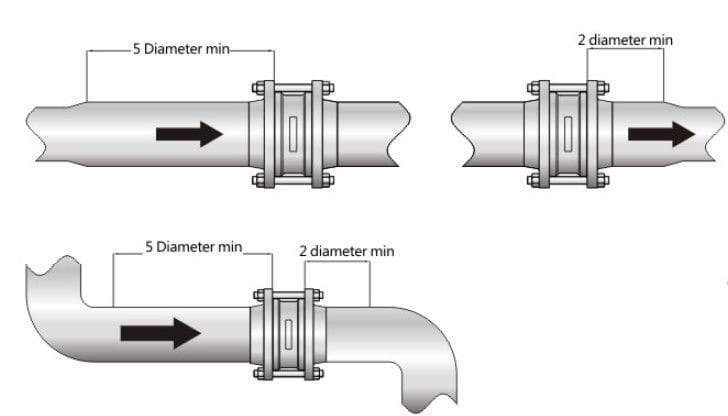

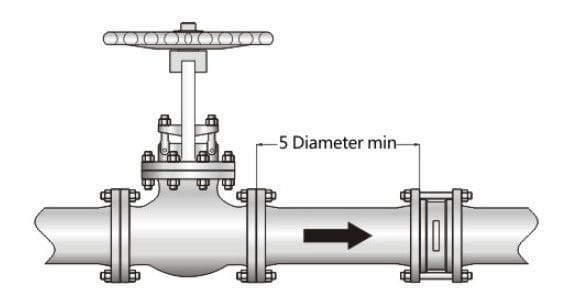

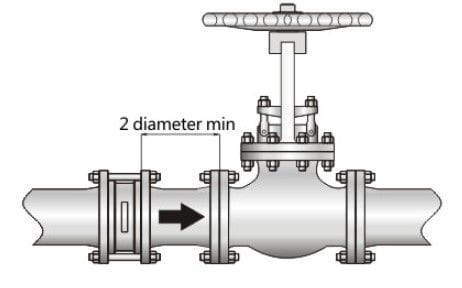

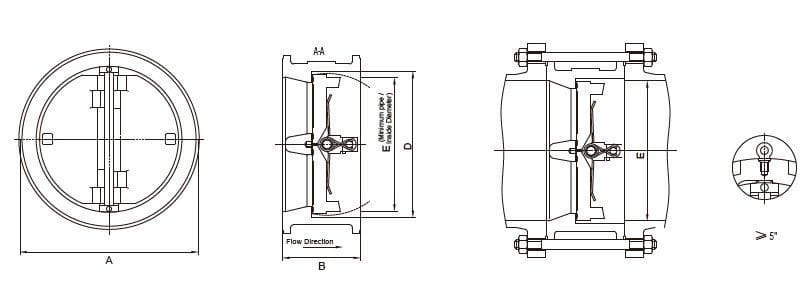

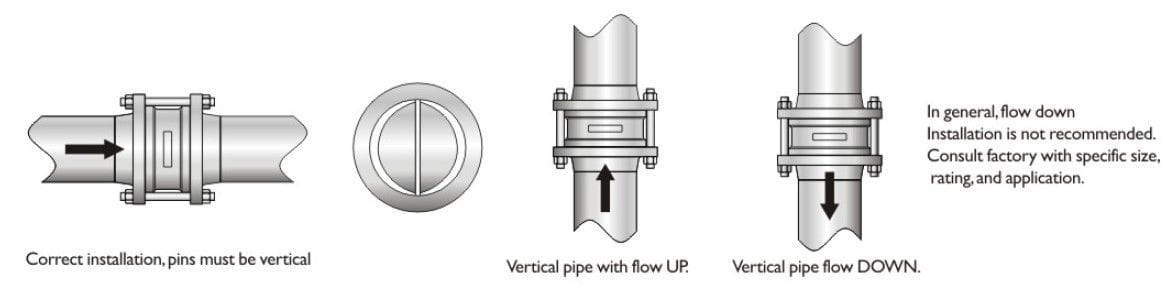

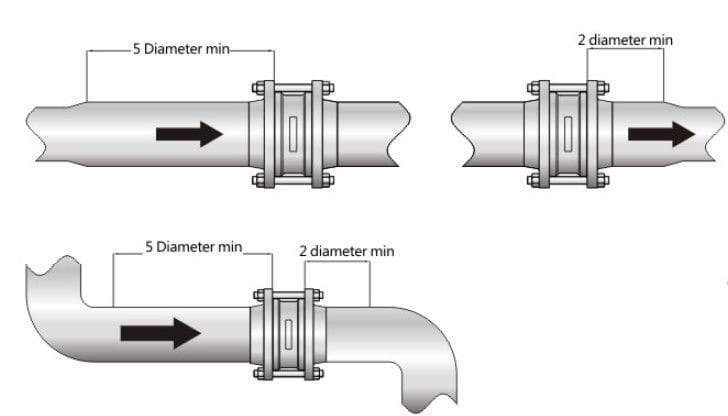

Recommended Installation

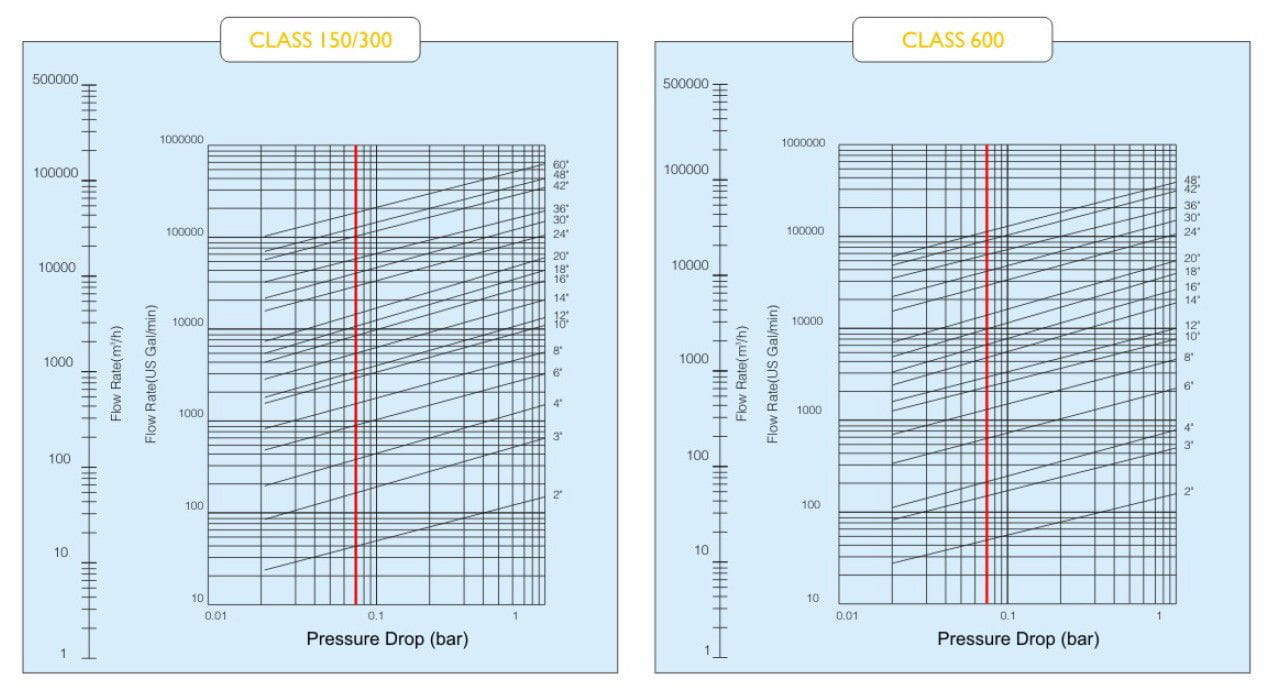

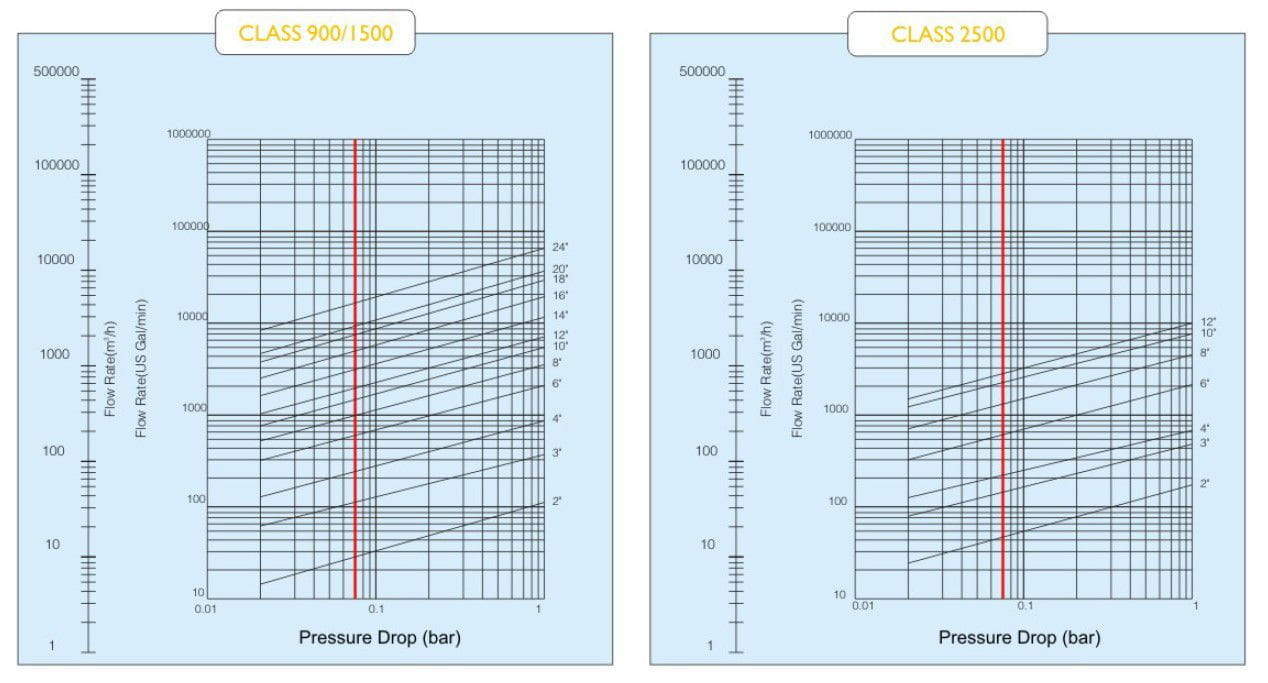

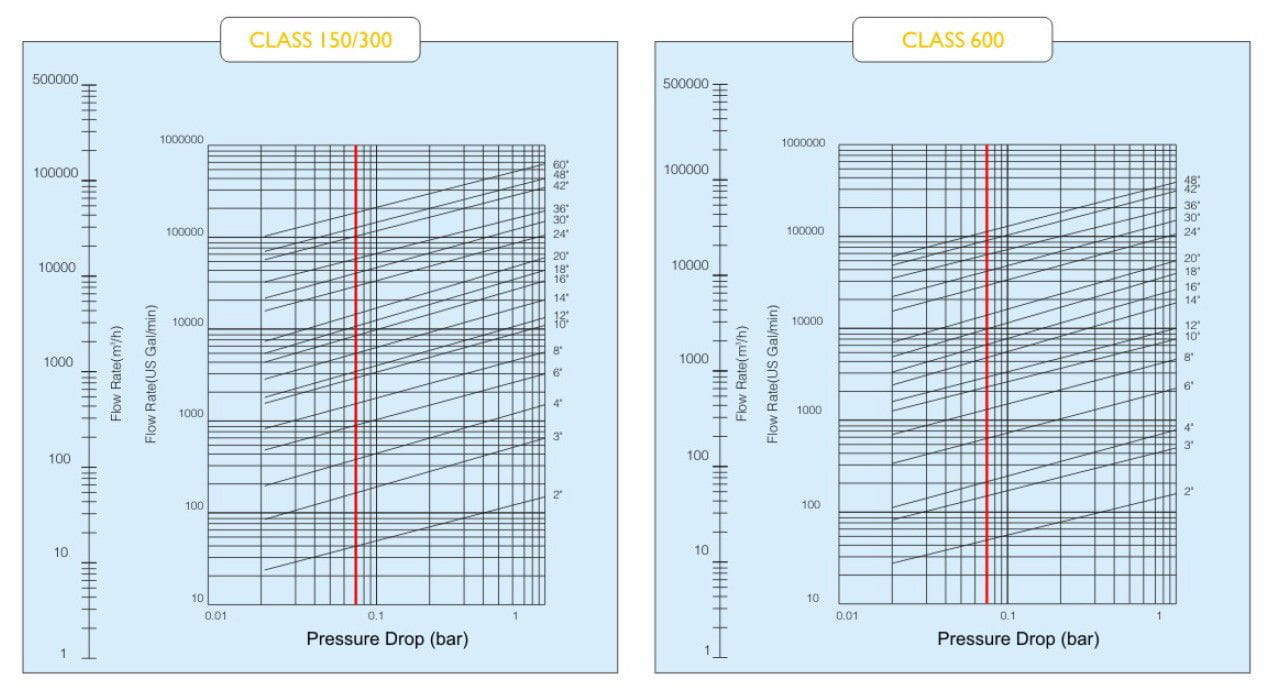

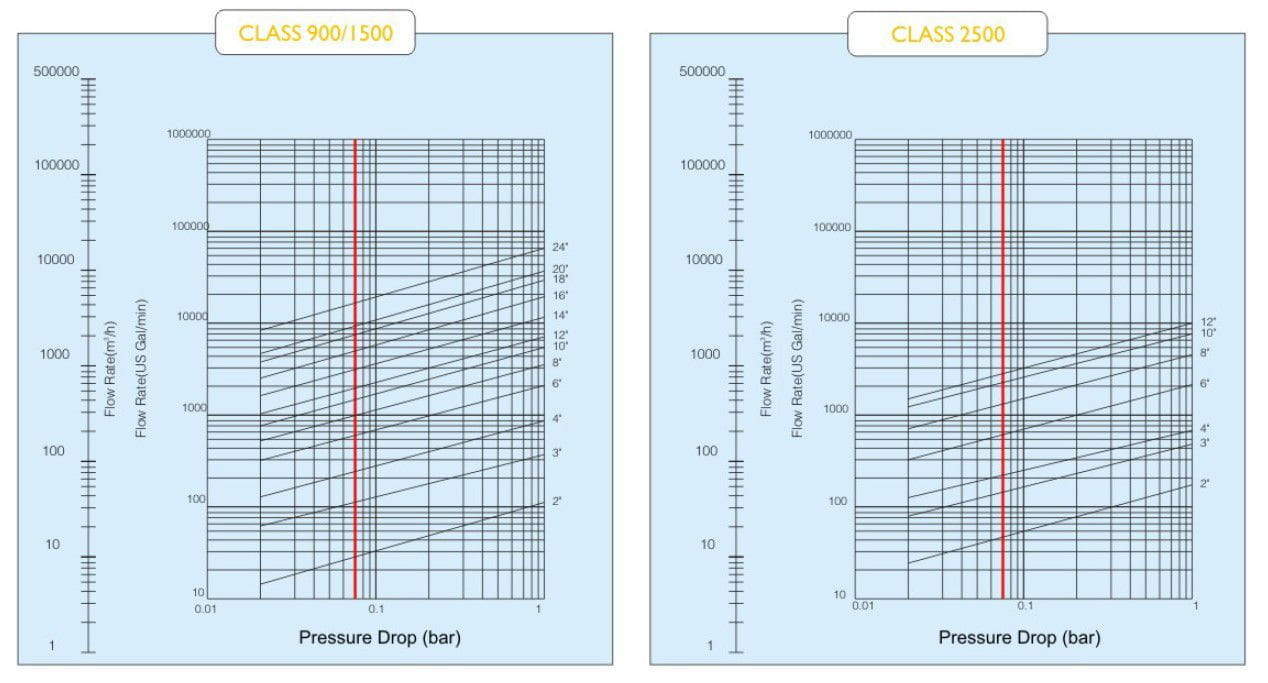

Flow Coefficient/Pressure loss

It’s made of a one-piece body, a pin at the centerline and two plates fixed by the pin and loaded with spring, it allows fluid to pass through in the flow direction and block the fluid when the flow return.

Compared with conventional swing check valves it can significantly reduce the weight and length and it results in saving cost and space of the piping system.

Compact Design

The weight is only around 20% of the equivalent swing check valve.

Swing Check Valve VS Dual Plate Check Valve

End Connections

Wafer End

Lug End

Flanged End

Retainerless Body

The bosseal dual plate valve is a one-piece design without a hole through the body, there are no external pins to retain the disc/stem, so that no external leakage point, it's a good choice for critical service.

Independent Spring

The two plates are actuated by two separate high torsion springs and it ensures a quick closing, lower water hammer affection, longer working life and better sealing performance.

Optional Soft and Metal Seat

Metal Seat: STL (CoCr alloy) overlay on the body seat, suitable for high temperature

Soft Seat: Viton, EPDM, NBR, PTFE (not recommended)

Unique Slim Plate Design

The plate size and shape are well designed to have lightweight, good flow efficiency, low-pressure loss, fast operation and better sealing performance under low pressure.

Other Wafer Check Valve Types are Available

Single Plate Wafer Check Valve

Thin Type Wafer Check Valve

Titling Disc Wafer Check Valve

Piston Type (Lifting) Wafer Check Valve

Recommended Installation

Flow Coefficient/Pressure loss

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China