Double Offset Butterfly Valve

- Home/

- Products/

- Butterfly Valves/

- Double Offset Butterfly Valve

With our state-of-the-art facilities and skilled workforce, we're able to deliver top-quality double offset butterfly valves as one of the leading manufacturers in China.

Design Standards: API 609 Cat B

Size Range: 2 - 72 Inch

Pressure Range: Class 150-300 LB

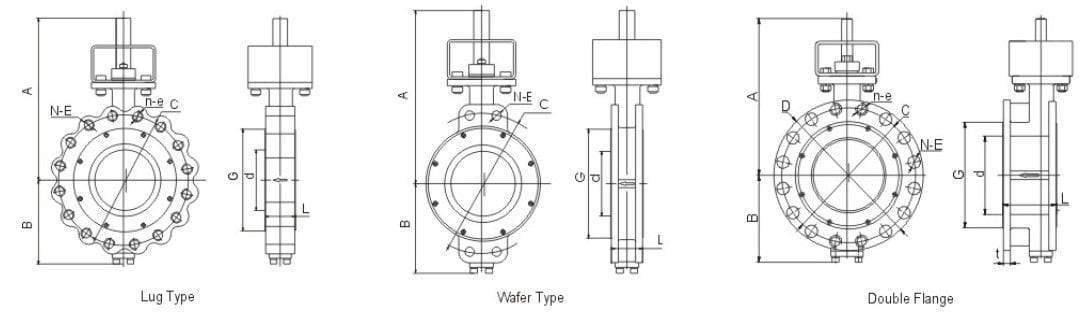

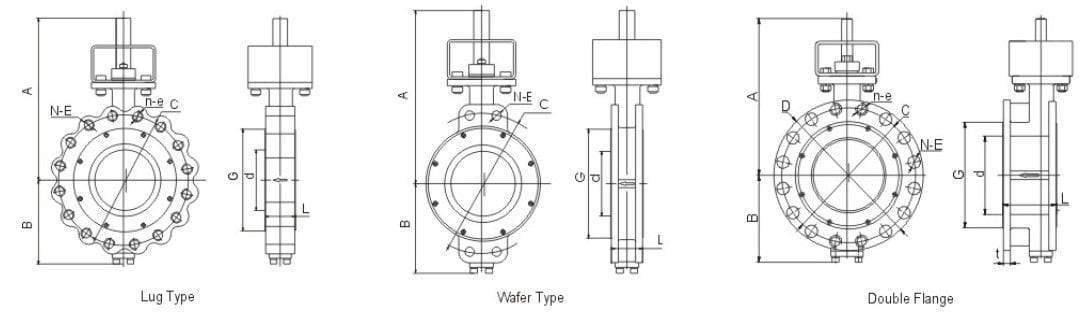

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ)

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

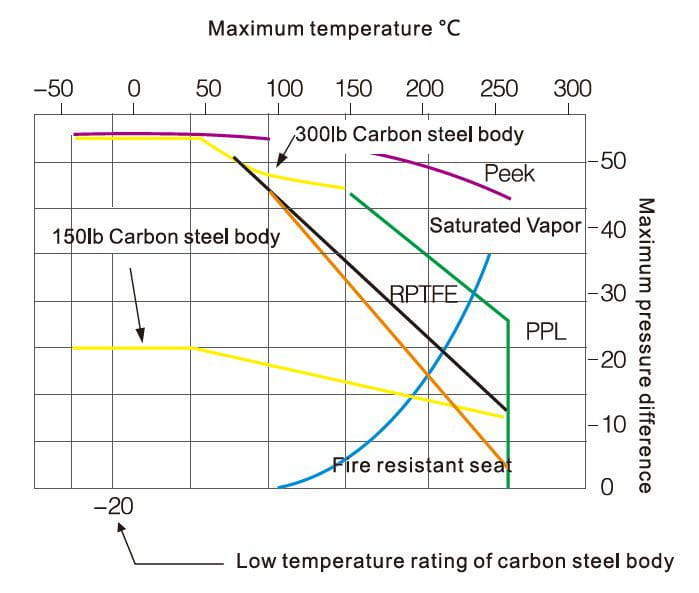

Seat Type: PTFE, RPTFE, PPL (for higher temperature), RPTFE+Metal (Fire Safe)

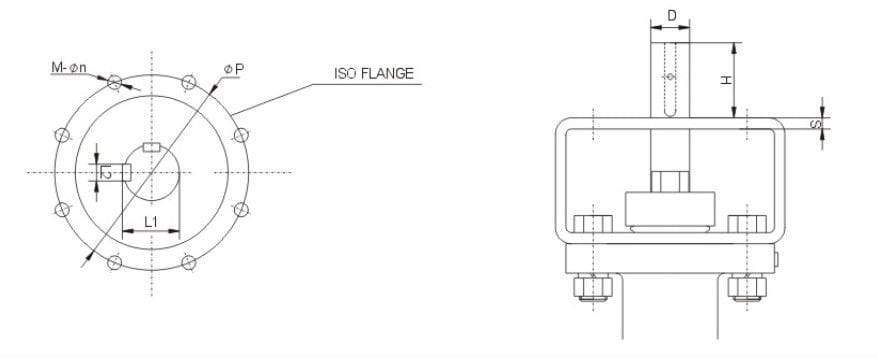

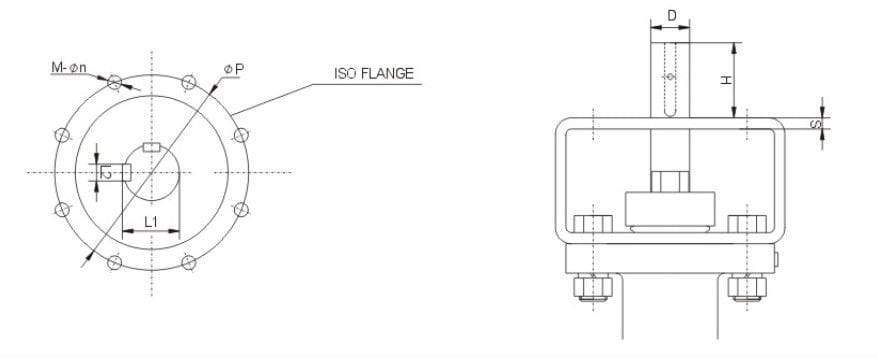

Top Mounting: ISO 5211 top mounting is available

Operation Types: Lever, Gear, Pneumatic Actuator

Bosseal Valve advantages: 0 Leakage, low Torque, Long working life, Low Emission, Bi-direction and fire safe

Design Standards: API 609 Cat B

Size Range: 2 - 72 Inch

Pressure Range: Class 150-300 LB

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ)

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Seat Type: PTFE, RPTFE, PPL (for higher temperature), RPTFE+Metal (Fire Safe)

Top Mounting: ISO 5211 top mounting is available

Operation Types: Lever, Gear, Pneumatic Actuator

Bosseal Valve advantages: 0 Leakage, low Torque, Long working life, Low Emission, Bi-direction and fire safe

Showing 1–12 of 400 results

Best QUALITY Double Offset Butterfly ValveS FOR YOU

A double offset butterfly valve is widely used in the pipeline for isolation and regulating applications, especially where request frequent open/close.

If you need any support with our Ball Valves, pls contact us!

Request a quote

If you need any support with our Ball Valves, pls contact us!

DOUBLE OFFSET BUTTERFLY VALVE

A double offset butterfly valve is widely used in the pipeline for isolation and regulating applications, especially where request frequent opening/closing.

Double Eccentric Butterfly Valve:

Compared to other valve types, it's obviously cost and space-saving and has a bigger size range, the operation is faster and there is less restriction and wear between the disc and seat sealing surface. It will ensure longer cycling life and reduce the total cost of ownership.

With 2 offsets the valve is with longer working life and lower torque and is suitable for frequent operation service, Bosseal high-performance butterfly valves have passed a million cycling tests.

Main Features:

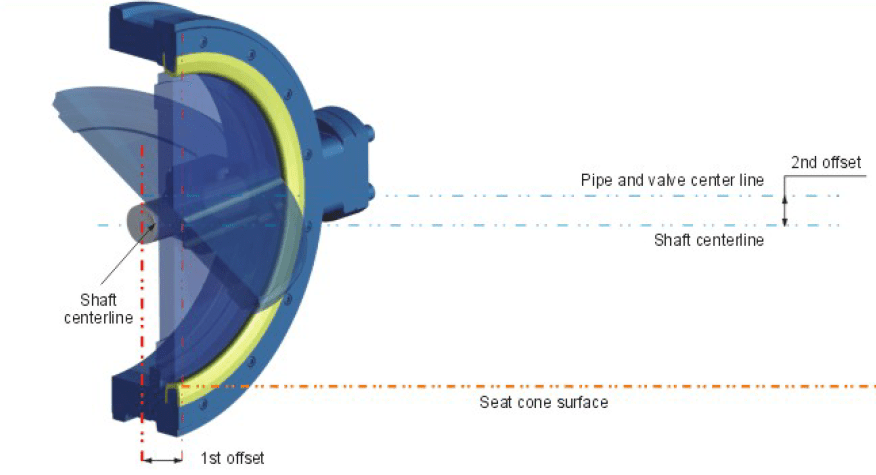

Offset Design

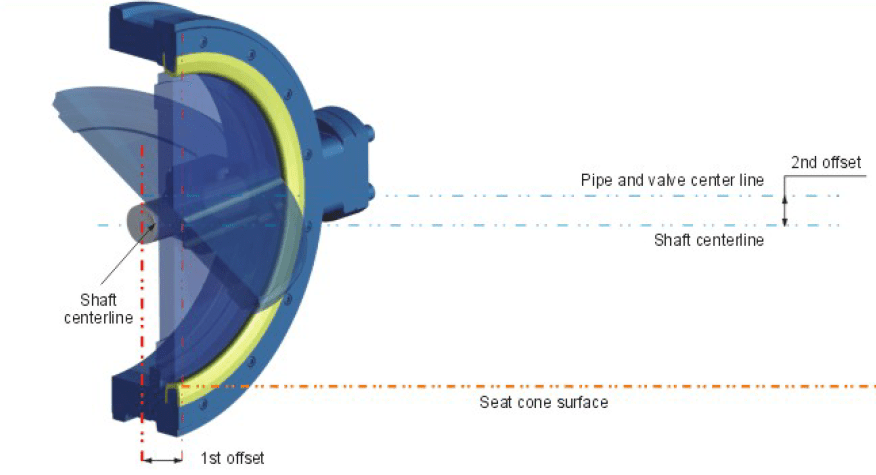

1st offset: shaft centerline behind disc centerline, it can reduce the contact between disc and seat fore fully close, and allow for a continuous engagement of the seating surface.

2nd offset: shaft centerline offset from centerline of the valve and pipe, the sealing surface is linear so when open the valve the disc seal will quickly leave the seat and it can significantly reduce the friction/wear of sealing surfaces

Compact Design & Low Emission and anti-blowout stem design

ISO 5211 Top Mounting

Different End Connections Available:

Dead End Service

When the valves need to be installed at end of the pipe and one side has no connection with the ant pipe/flange, the valve needs a special design like threaded holes and bi-direction sealing.

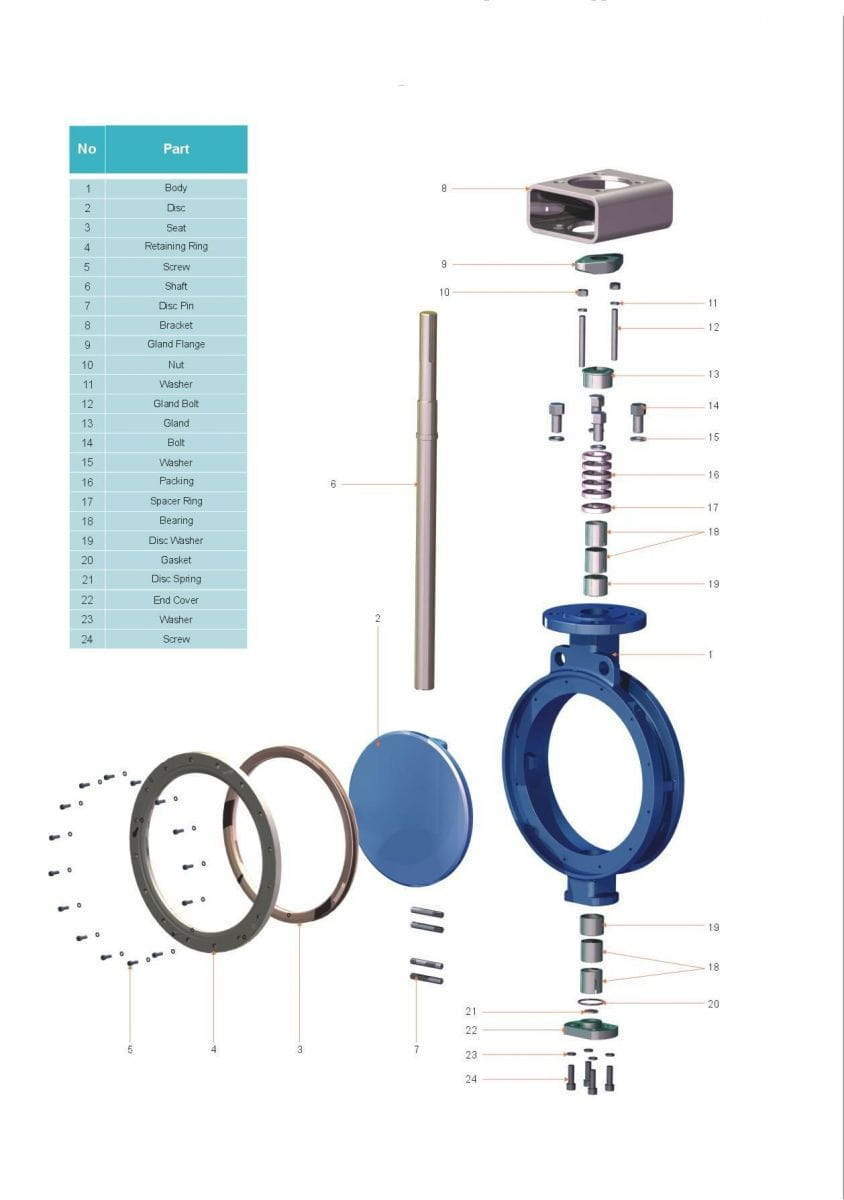

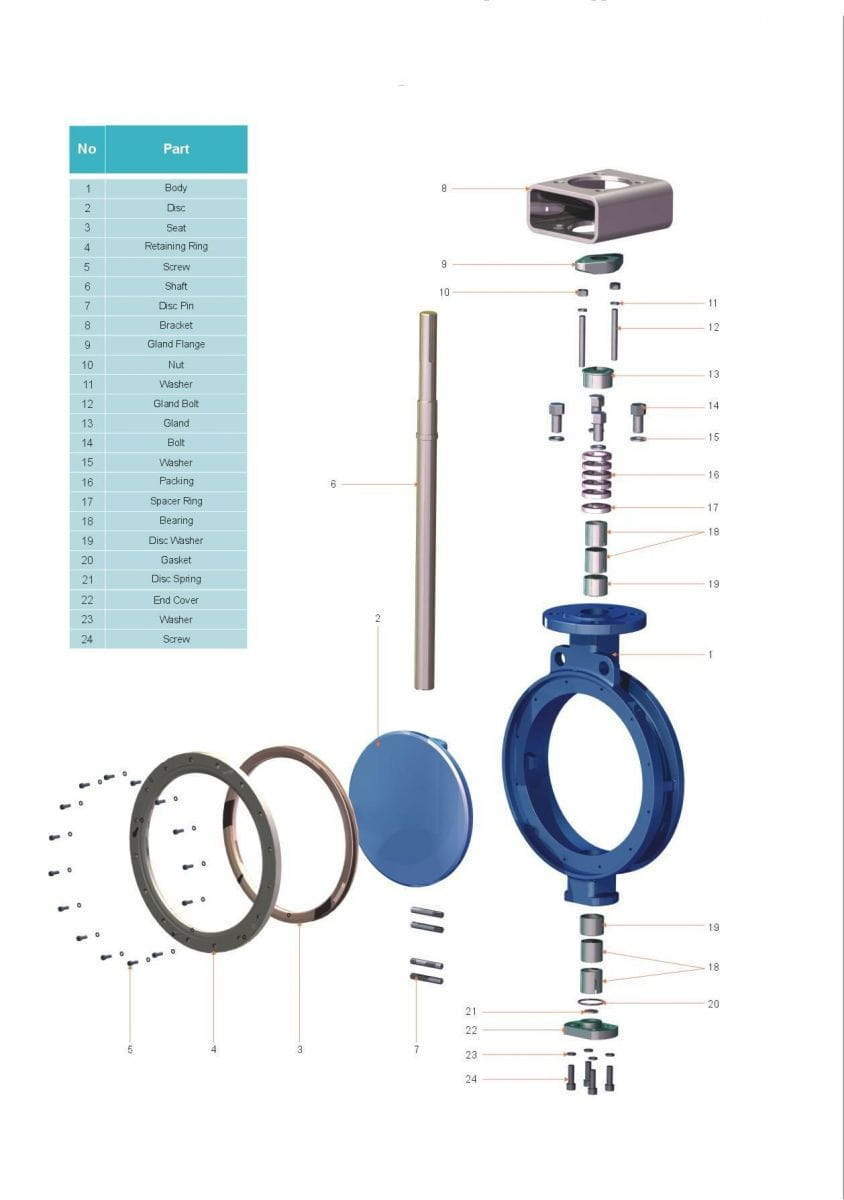

Easy Maintenance

The seat is replaceable and can be easily disassembled by losing the seat retainer with special tools.

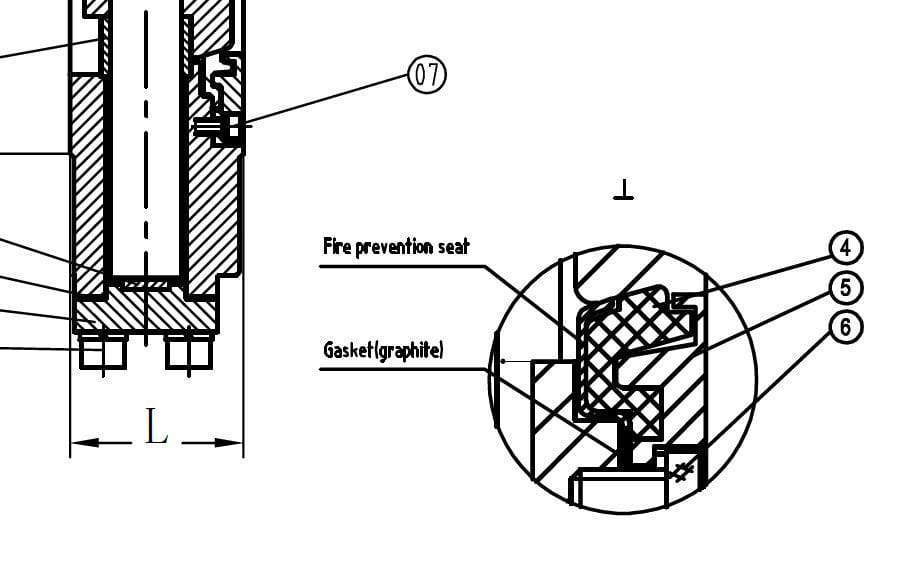

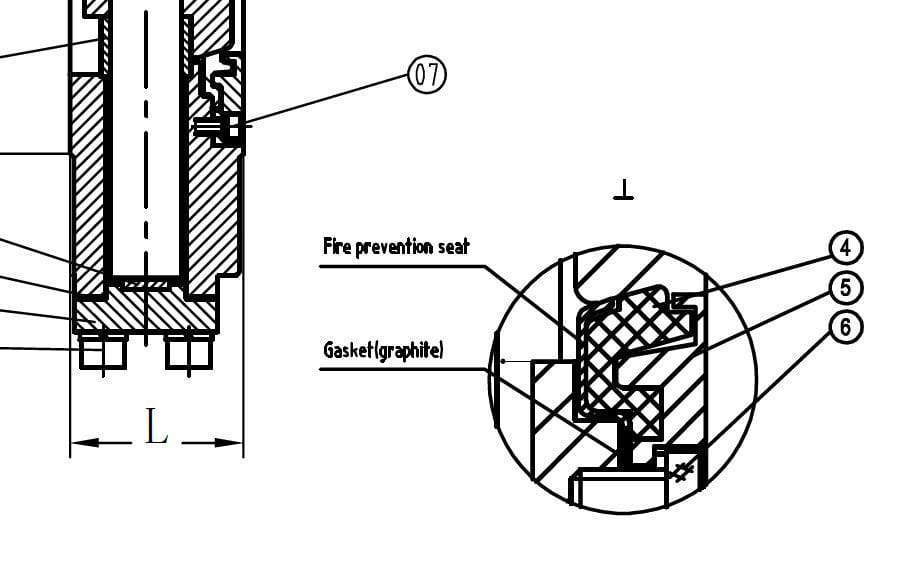

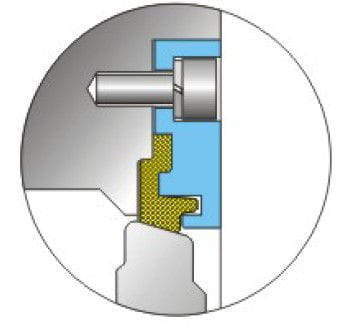

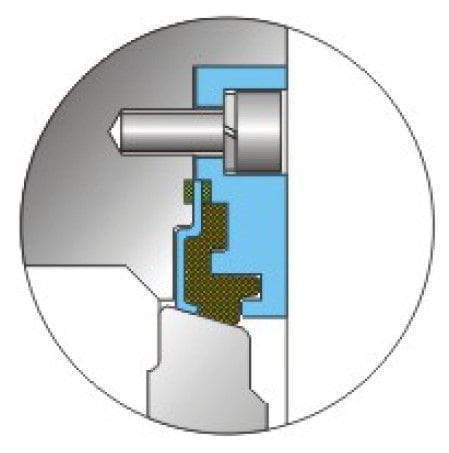

Fire Safe Seat

Fire safe with dual seal including primary soft PTFE seat and secondary metal seat, in event of a fire the soft seat is destroyed the metal seat will provide effective shut-off.

Comparison of non-fire safe and fire safe design

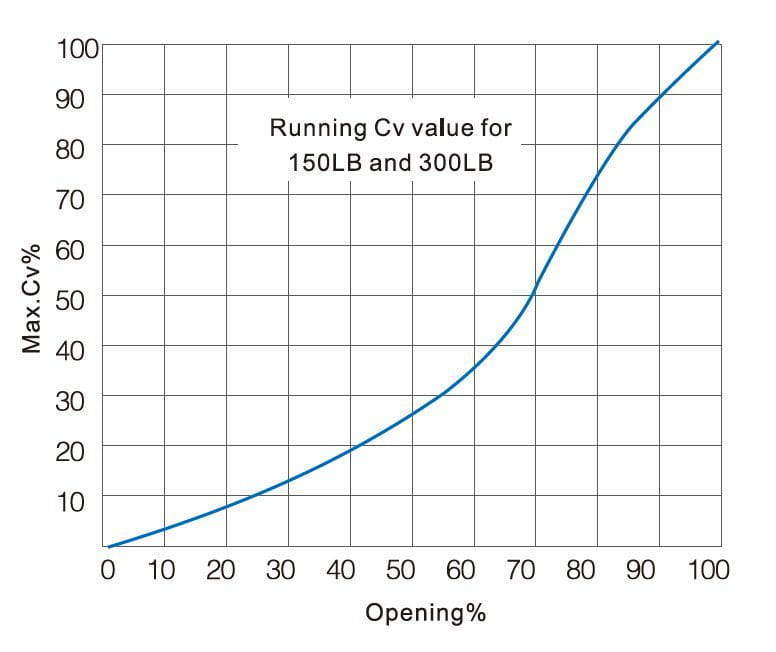

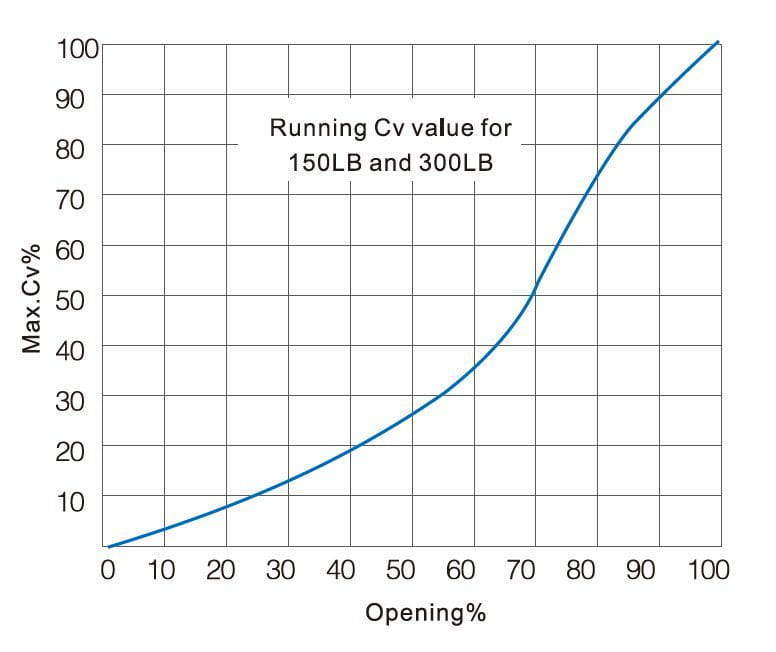

CV Value

Flow parameters

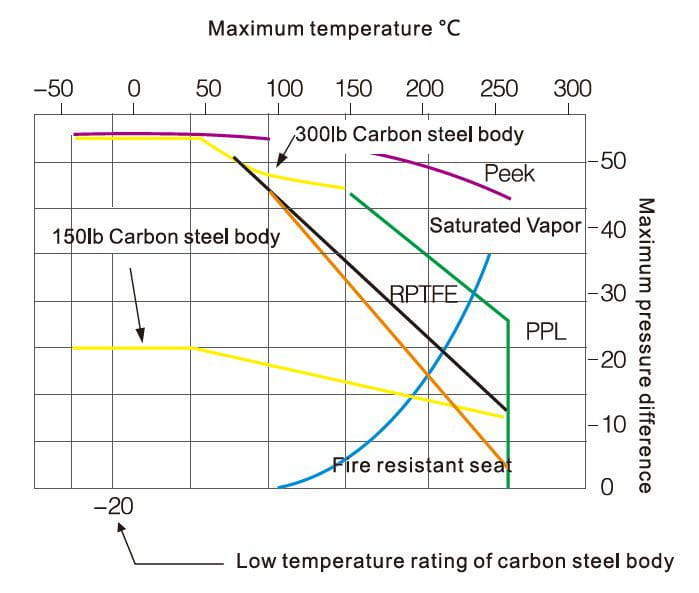

Temperature-Pressure Rating of Seats

A double offset butterfly valve is widely used in the pipeline for isolation and regulating applications, especially where request frequent opening/closing.

Double Eccentric Butterfly Valve:

Compared to other valve types, it's obviously cost and space-saving and has a bigger size range, the operation is faster and there is less restriction and wear between the disc and seat sealing surface. It will ensure longer cycling life and reduce the total cost of ownership.

With 2 offsets the valve is with longer working life and lower torque and is suitable for frequent operation service, Bosseal high-performance butterfly valves have passed a million cycling tests.

Main Features:

Offset Design

1st offset: shaft centerline behind disc centerline, it can reduce the contact between disc and seat fore fully close, and allow for a continuous engagement of the seating surface.

2nd offset: shaft centerline offset from centerline of the valve and pipe, the sealing surface is linear so when open the valve the disc seal will quickly leave the seat and it can significantly reduce the friction/wear of sealing surfaces

Compact Design & Low Emission and anti-blowout stem design

ISO 5211 Top Mounting

Different End Connections Available:

Dead End Service

When the valves need to be installed at end of the pipe and one side has no connection with the ant pipe/flange, the valve needs a special design like threaded holes and bi-direction sealing.

Easy Maintenance

The seat is replaceable and can be easily disassembled by losing the seat retainer with special tools.

Fire Safe Seat

Fire safe with dual seal including primary soft PTFE seat and secondary metal seat, in event of a fire the soft seat is destroyed the metal seat will provide effective shut-off.

Comparison of non-fire safe and fire safe design

|

|

CV Value

Flow parameters

Temperature-Pressure Rating of Seats

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China