ASTM A890 4A

Butterfly Valve, 26 Inch/DN650, 150 LB, Wafer End.

1862172 High-Performance Butterfly Valve

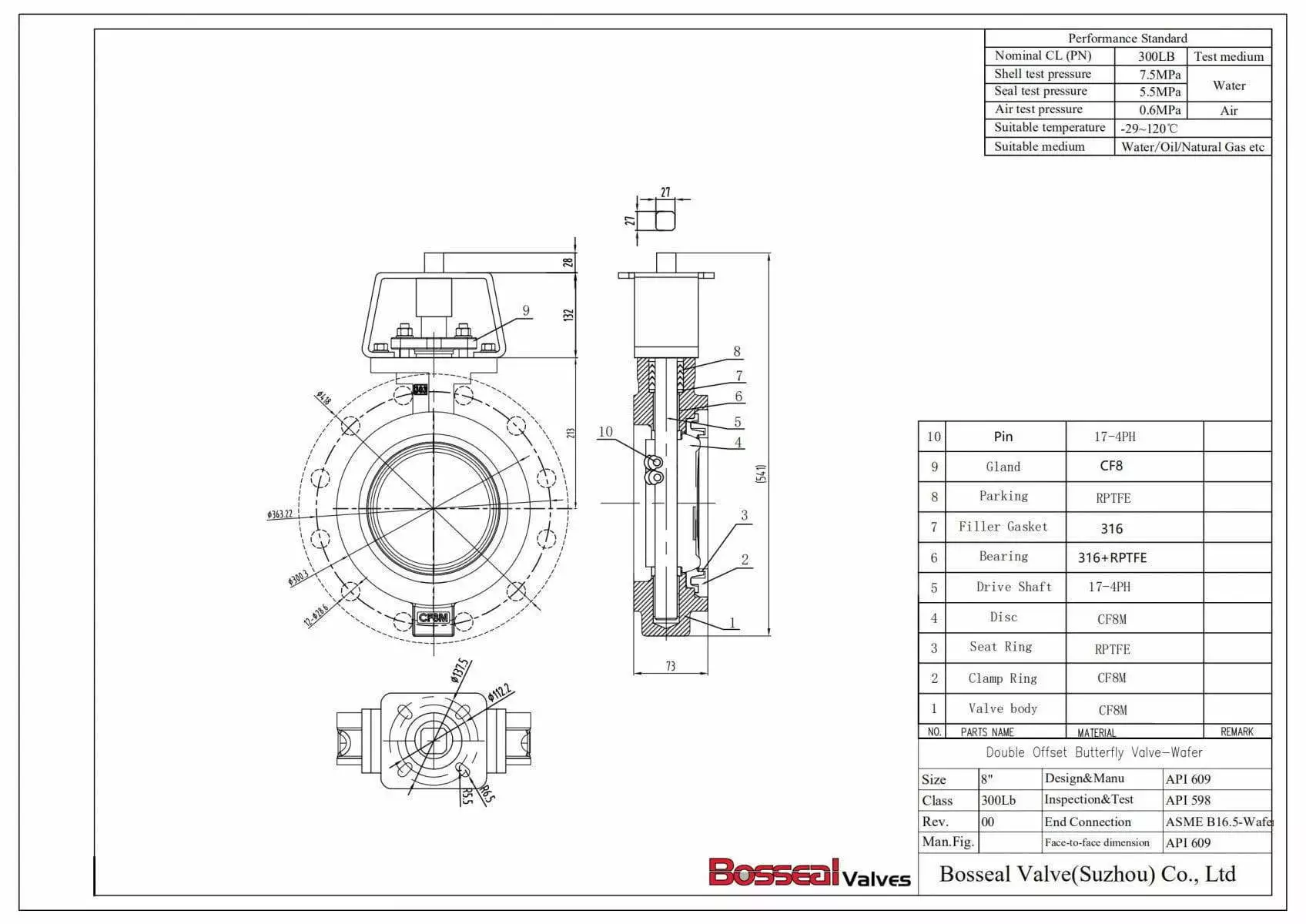

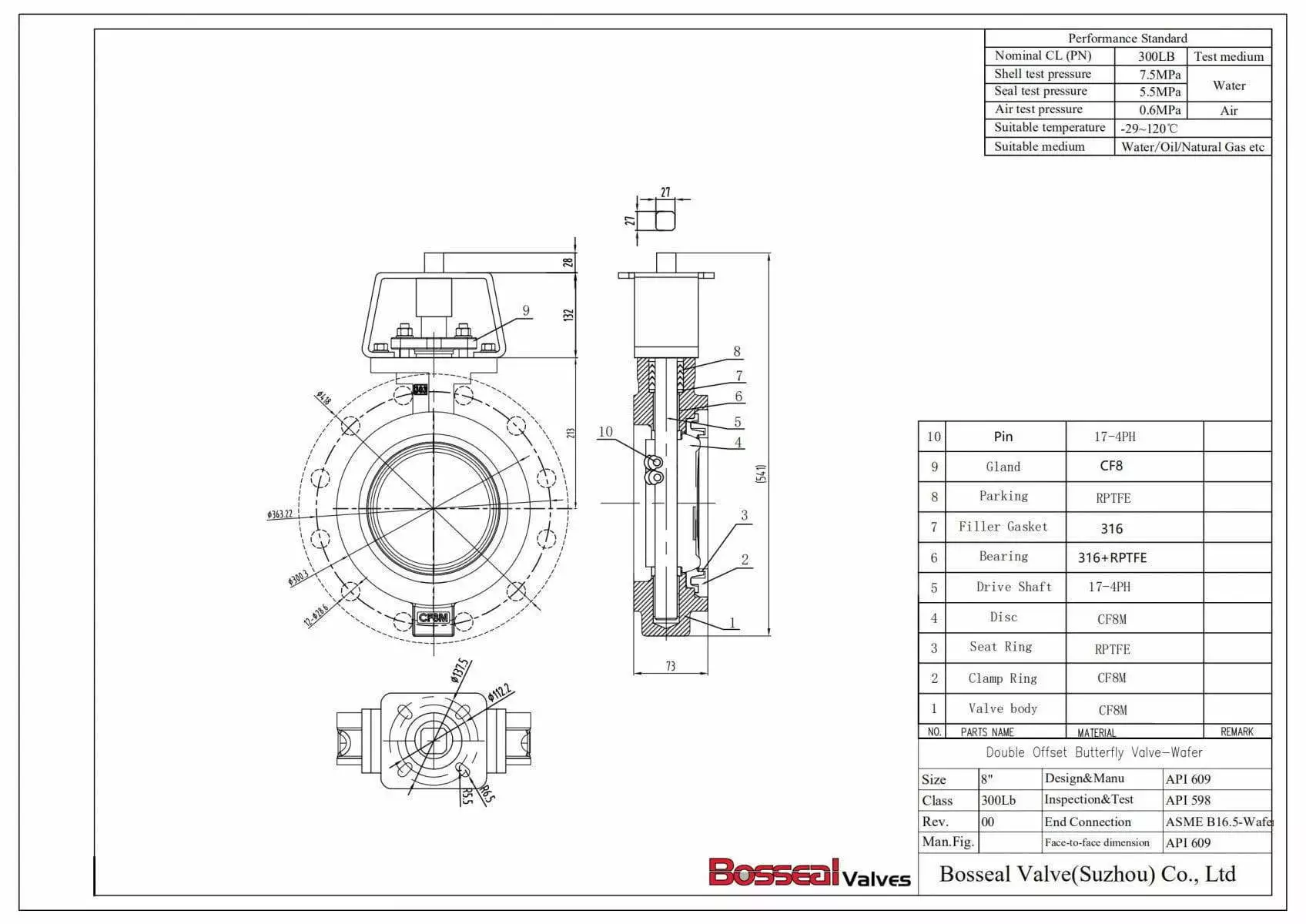

Design Standard: API 609 Category B, EN 593

Body Material: ASTM A890 4A, ASTM B148 C95800, ASTM A216 WCB, ASTM A890 5A, ASTM A351 CF8M, ASTM A351 CF8, Titanium.

Nominal Size: 26 Inch, DN650

Nominal Class: Class 150 LB, PN16

Seat Type: Soft Seat

Operation: Gear

Seat: RPTFE, PPL

End Connection: Wafer

Structure: Double Offset, Double Eccentric

Trim Material: ASTM A351 CF8, ASTM A351 CF8M, ASTM A890 4A, ASTM A890 5A, ASTM B148 C95800, Titanium

Face to Face: API 609, EN 593

Test and Inspection: API 598, API 609

Key Features: Long working life for frequent operation (million cyclings), Lower torque, Replaceable seat, Tight sealing, Excellent control characteristics, Bi-direction sealing under full pressure, fire safe seat available.

Body Material: Carbon Steel, Stainless Steel, Duplex Steel, Aluminum Bronze, Titanium

Normal Diameter: 1/2 - 48 Inch (DN15 - DN1200)

Pressure Range: Class 150 LB - 300 LB

Operation: Manual (lever, gear), Pneumatic Actuator, Motor Actuator

Working Temperature: -26°C - +120°C (180°C for PPL seat)

End Connection: Wafer, Lug, Flanged

Compared to other valve types, double eccentric butterfly valves offer significant cost and space savings, along with a broader size range. They operate faster, with less restriction and reduced wear between the disc and seat sealing surfaces, ensuring a longer service life and lower total cost of ownership. The two-offset design enhances durability and reduces torque, making these valves ideal for frequent operation. Bosseal’s high-performance butterfly valves have successfully passed a million-cycle test, ensuring long-lasting reliability.