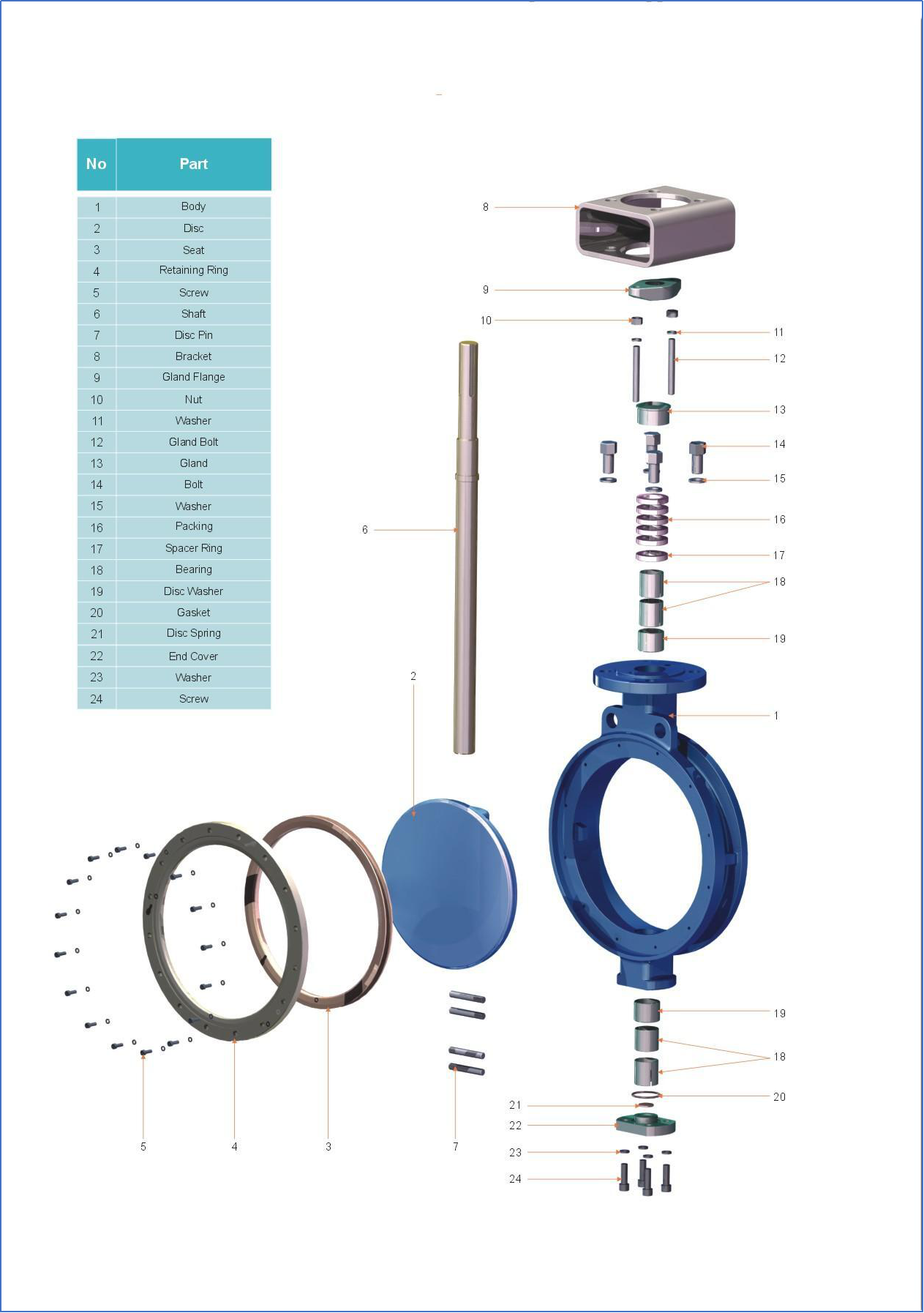

ASTM A351 CF8

Butterfly Valve, 24 Inch/DN600, 300 LB, Wafer End.

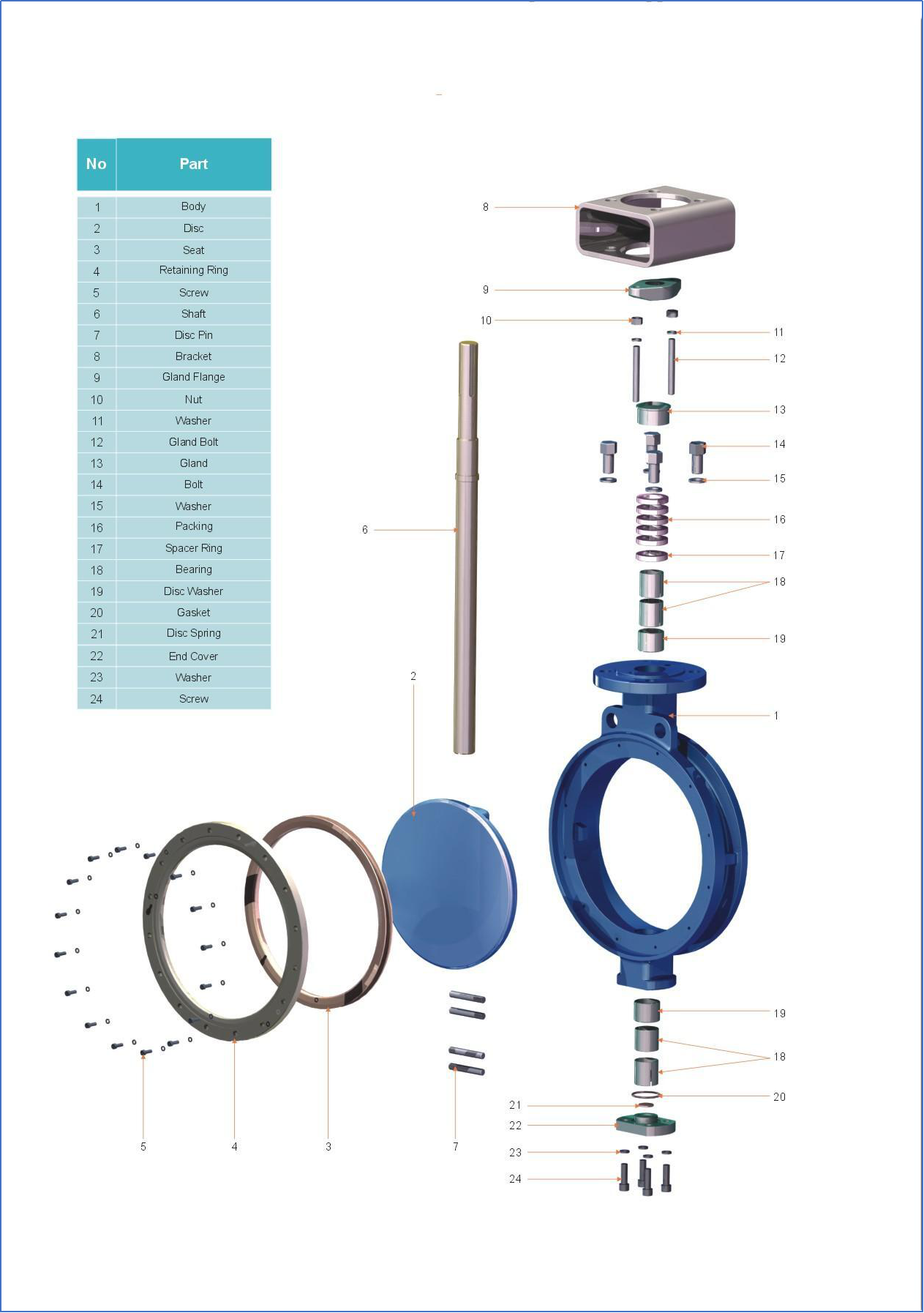

| 1862192 High-Performance Butterfly Valve |

| Design Standard: |

API 609 Category B, EN 593 |

| Body Material: |

ASTM A351 CF8, ASTM A890 4A, ASTM B148 C95800, ASTM A216 WCB, ASTM A890 5A, ASTM A351 CF8M, Titanium. |

| Nominal Size: |

24 Inch, DN600 |

| Nominal Class: |

CL 300 LB, PN50 |

| Seat Type: |

Soft Seat |

| Operation: |

Gear |

| Seat: |

RPTFE, PPL |

| End Connection: |

Wafer |

| Structure: |

Double Offset, Double Eccentric |

| Trim Material: |

ASTM A351 CF8, ASTM A351 CF8M, ASTM A890 4A, ASTM A890 5A, ASTM B148 C95800, Titanium |

| Face to Face: |

API 609, EN 593 |

| Test and Inspection: |

API 598, API 609 |

| Key Features: |

Long working life for frequent operation (million cyclings), Lower torque, Replaceable seat, Tight sealing, Excellent control characteristics, Bi-direction sealing under full pressure, fire safe seat available. |

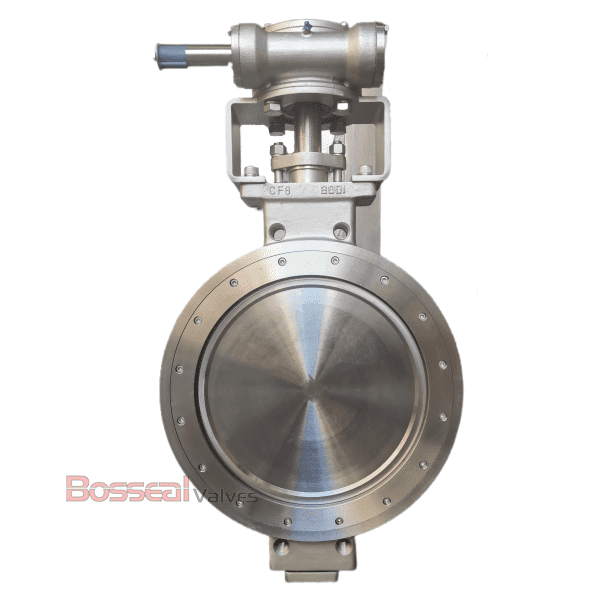

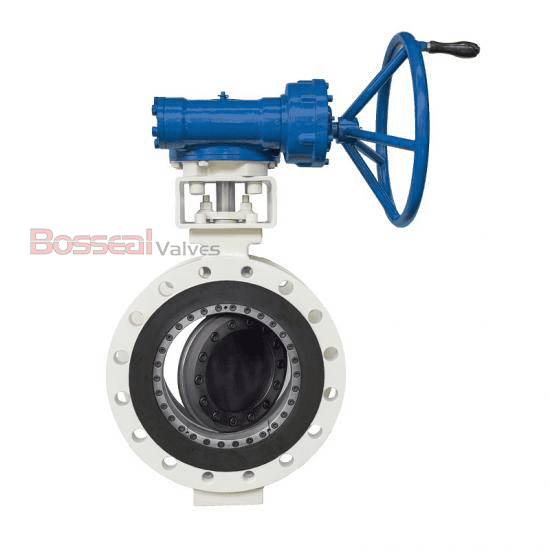

Body Material: Carbon Steel, Stainless Steel, Duplex Steel, Aluminum Bronze, Titanium

Normal Diameter: 1/2 - 48 Inch (DN15 - DN1200)

Pressure Range: Class 150 - 300 LB

Operation: Manual (lever, gear), Pneumatic Actuator, Motor Actuator

Working Temperature: -26°C - +120°C (180°C for PPL seat)

End Connection: Wafer, Lug, Flanged(FF, RF, RTJ)

Top Mounting: ISO 5211 Top Mounting Available

Operation Types: Lever, Gear, Pneumatic Actuator

Main Features

1st offset: The shaft centerline is positioned behind the disc centerline, reducing contact between the disc and seat during closure and allowing continuous engagement with the seating surface.

2nd offset: The shaft centerline is offset from the valve and pipe centerline, creating a linear sealing surface. This ensures that as the valve opens, the disc seal quickly disengages from the seat, minimizing friction and wear on the sealing surfaces.

With a shorter face-to-face dimension and lightweight structure, it saves space in piping systems compared to other valve types.

Pre-compressed flexible graphite packing ensures lower torque and better sealing, with controlled stem and stuffing box roughness. The live-loaded gland flange allows easy packing adjustment, while the space ring and gland prevent stem blowout.