Our company is among the top-tier check valve manufacturers in China.

Valve Types: Swing Check Valve, API 6D Full Open Swing Check Valve, Lifting Check Valve, Dual Plate Check Valve, Axial Flow Check Valve, Titling Check Valve, Single Plate Wafer Check Valve

Design Standards: BS1868, API 594, API 602, ASME B16.34, API 6D

Size Range: 1/2 - 64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Flanged (FF, RF, RTJ), Socket Weld (SW), Threaded (NPT, BSP), Butt Weld (BW), Wafer, Lug

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy

Disc Types: single plate, dual plate, tilting disc

Bonnet Types: Bolted Bonnet, Pressure Bonnet, Welded Bonnet

Valve Types: Swing Check Valve, API 6D Full Open Swing Check Valve, Lifting Check Valve, Dual Plate Check Valve, Axial Flow Check Valve, Titling Check Valve, Single Plate Wafer Check Valve

Design Standards: BS1868, API 594, API 602, ASME B16.34, API 6D

Size Range: 1/2 - 64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Flanged (FF, RF, RTJ), Socket Weld (SW), Threaded (NPT, BSP), Butt Weld (BW), Wafer, Lug

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy

Disc Types: single plate, dual plate, tilting disc

Bonnet Types: Bolted Bonnet, Pressure Bonnet, Welded Bonnet

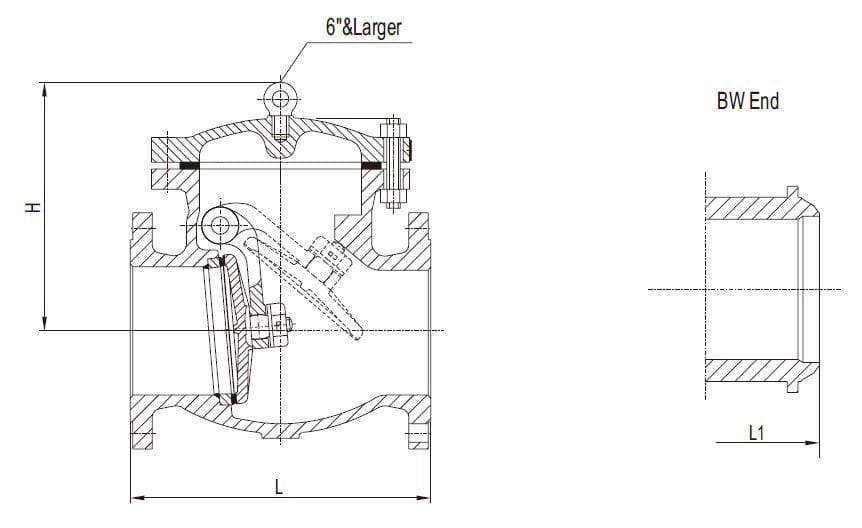

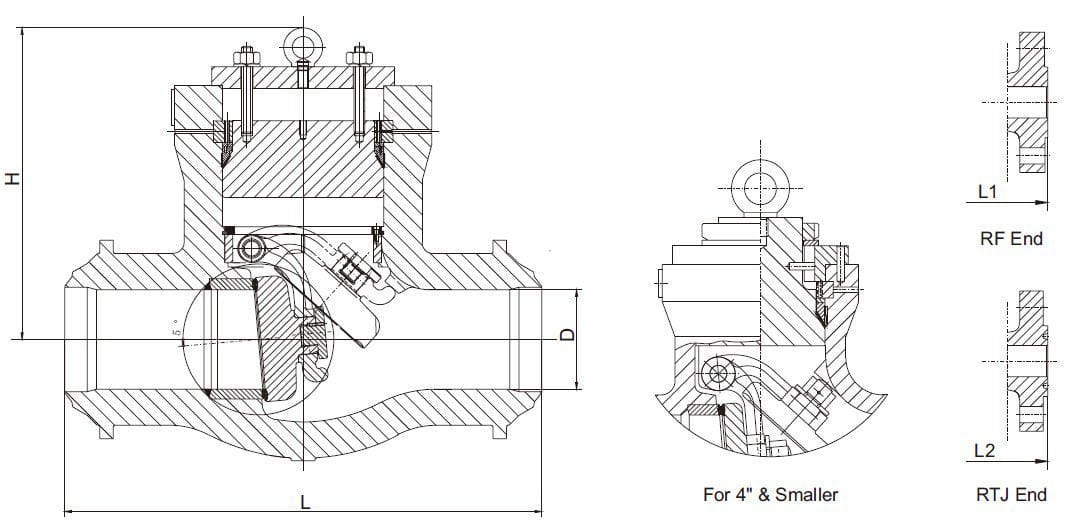

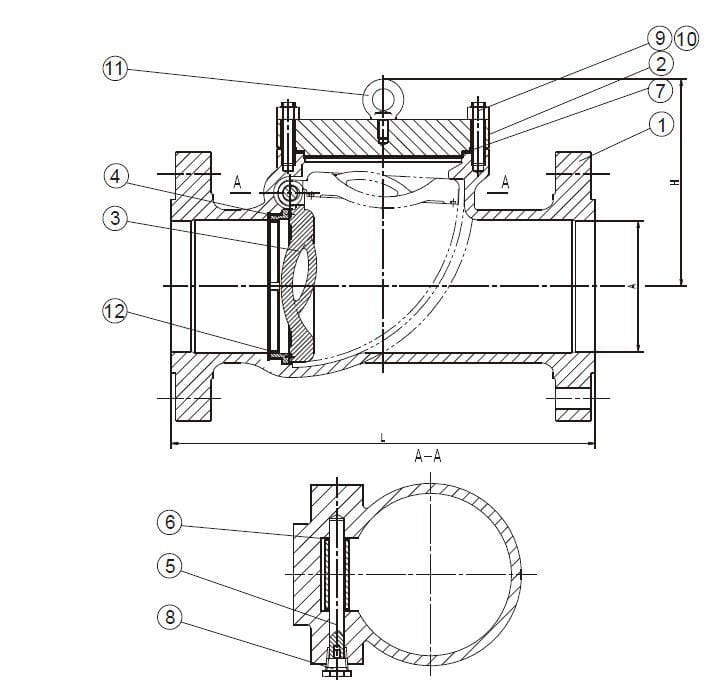

Swing Check Valve (88)

As one of the leading swing check valve manufacturers in China, we take pride in our products.

Valve Types: Swing Check Valve, API 6D Full Open Swing Check Valve

Design Standards: BS 1868, API 594, ASME B16.34, API 6D

Size Range: 1/2 - 64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Flanged (FF, RF, RTJ), Socket Weld (SW), Threaded (NPT, BSP), Butt Weld (BW)

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy

Bonnet Types: Bolted Bonnet, Pressure Bonnet, Welded Bonnet

Valve Types: Swing Check Valve, API 6D Full Open Swing Check Valve

Design Standards: BS 1868, API 594, ASME B16.34, API 6D

Size Range: 1/2 - 64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Flanged (FF, RF, RTJ), Socket Weld (SW), Threaded (NPT, BSP), Butt Weld (BW)

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy

Bonnet Types: Bolted Bonnet, Pressure Bonnet, Welded Bonnet

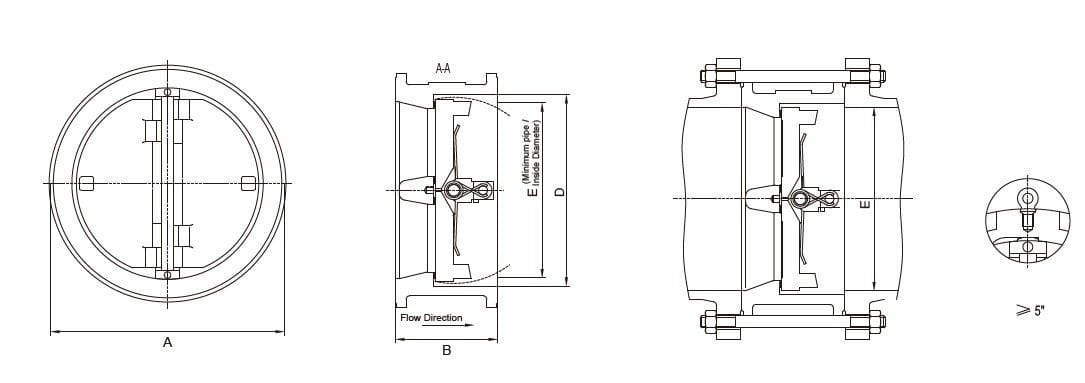

Dual Plate Check Valve (100)

With years of experience as a dual plate check valve manufacturer in China, we have a strong reputation in the industry.

Valve Types: Dual Plate Check Valve, Single Plate Wafer Check Valve, Thin Type WAFER Check Valve, Lifting Wafer Check Valve

Seat Type: Soft Seat, Metal Seat

Design Standards: API 594, API 6D

Size Range: 2-64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ), Butt Weld (BW), HUB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Valve Types: Dual Plate Check Valve, Single Plate Wafer Check Valve, Thin Type WAFER Check Valve, Lifting Wafer Check Valve

Seat Type: Soft Seat, Metal Seat

Design Standards: API 594, API 6D

Size Range: 2-64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ), Butt Weld (BW), HUB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

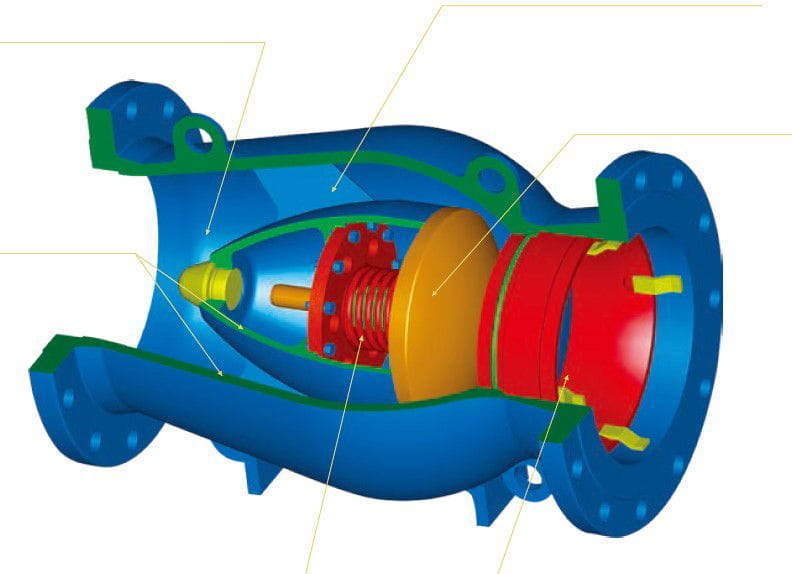

We have established ourselves as one of the most reputable axial flow check valve manufacturers in China.

Design Standards: API 594, API 6D

Size Range: 2 - 48 Inch

Pressure Range: Class 150-2500 LB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Design Standards: API 594, API 6D

Size Range: 2 - 48 Inch

Pressure Range: Class 150-2500 LB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

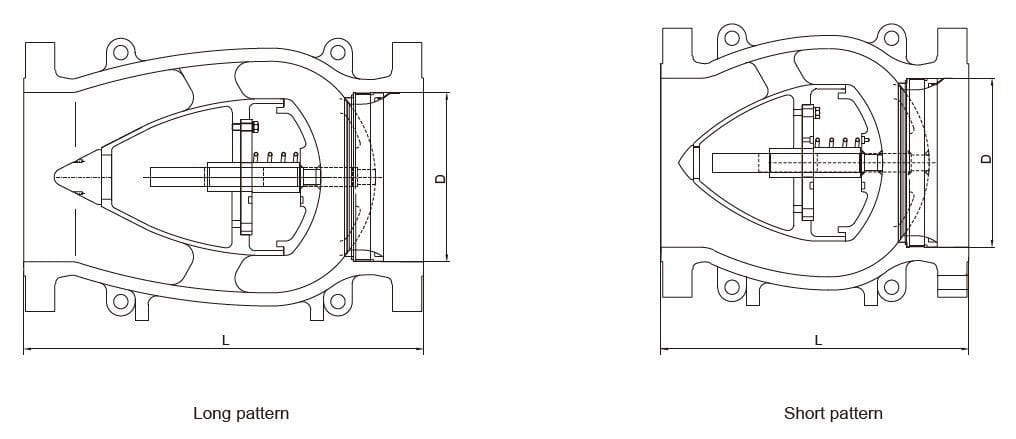

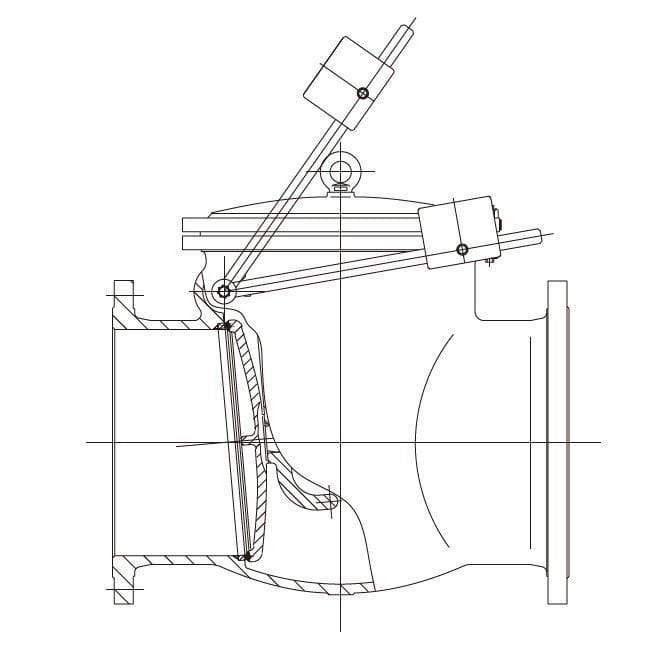

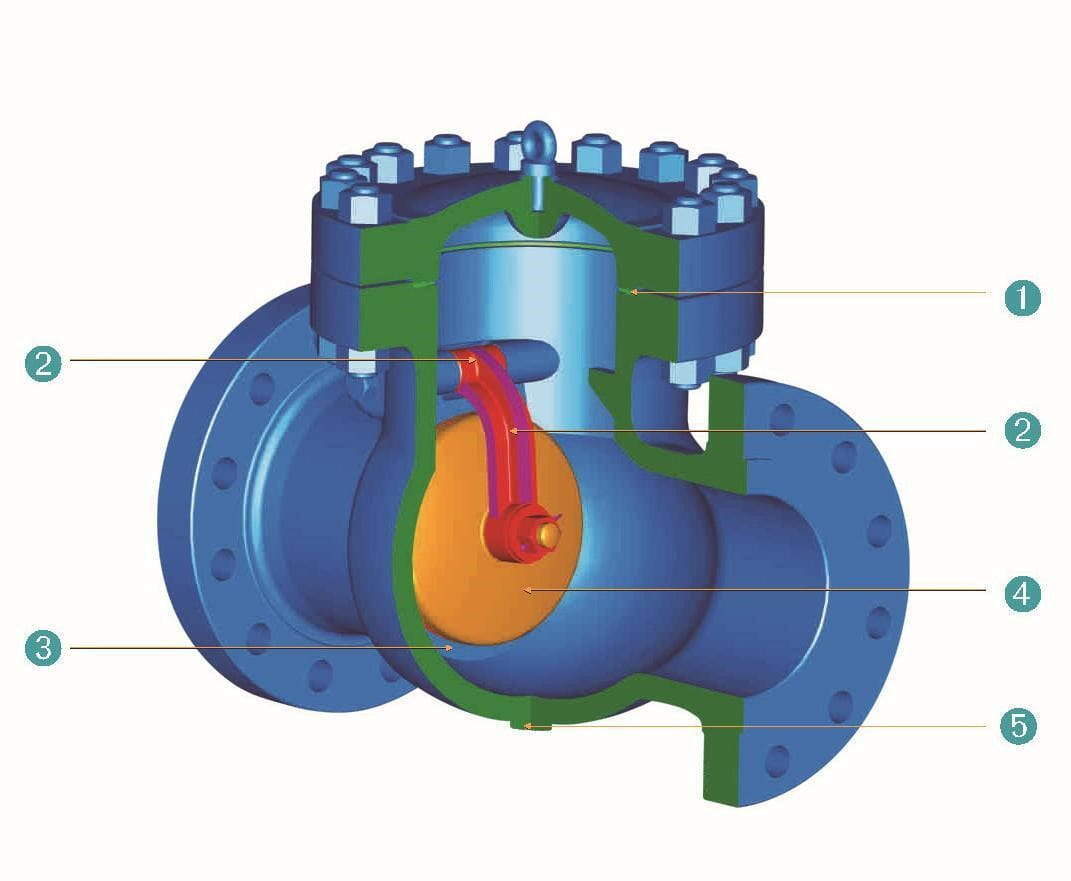

Swing Check Valve

Valve Types: Swing Check Valve, API 6D Full Open Swing Check Valve

Design Standards: BS 1868, API 594, ASME B16.34, API 6D

Size Range: 1/2 - 64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Flanged (FF, RF, RTJ), Socket Weld (SW), Threaded (NPT, BSP), Butt Weld (BW)

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy

Bonnet Types: Bolted Bonnet, Pressure Bonnet, Welded Bonnet

Request a quote

Design Standards: BS 1868, API 594, ASME B16.34, API 6D

Size Range: 1/2 - 64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Flanged (FF, RF, RTJ), Socket Weld (SW), Threaded (NPT, BSP), Butt Weld (BW)

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy

Bonnet Types: Bolted Bonnet, Pressure Bonnet, Welded Bonnet

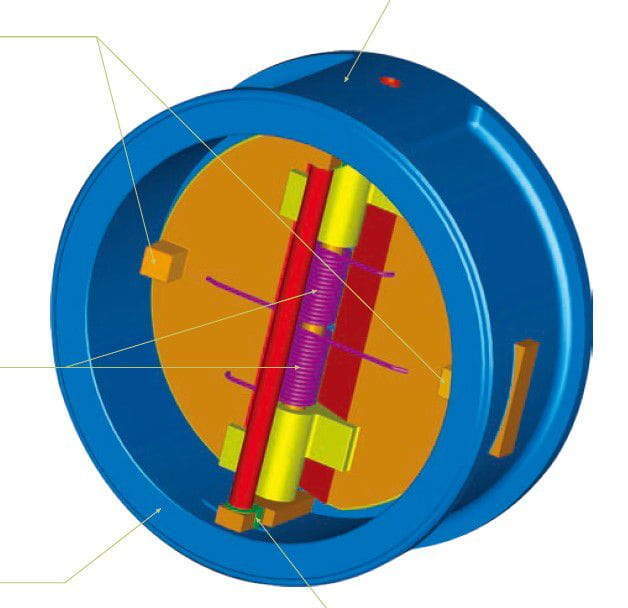

Dual Plate Check Valve

Valve Types: Dual Plate Check Valve, Single Plate Wafer Check Valve, Thin Type WAFER Check Valve, Lifting Wafer Check Valve

Seat Type: Soft Seat, Metal Seat

Design Standards: API 594, API 6D

Size Range: 2-64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ), Butt Weld (BW), HUB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Request a quote

Seat Type: Soft Seat, Metal Seat

Design Standards: API 594, API 6D

Size Range: 2-64 Inch

Pressure Range: Class 150-2500 LB

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ), Butt Weld (BW), HUB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Axial Flow Check Valve

Design Standards: API 594, API 6D

Size Range: 2 - 48 Inch

Pressure Range: Class 150-2500 LB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Request a quote

Size Range: 2 - 48 Inch

Pressure Range: Class 150-2500 LB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Application

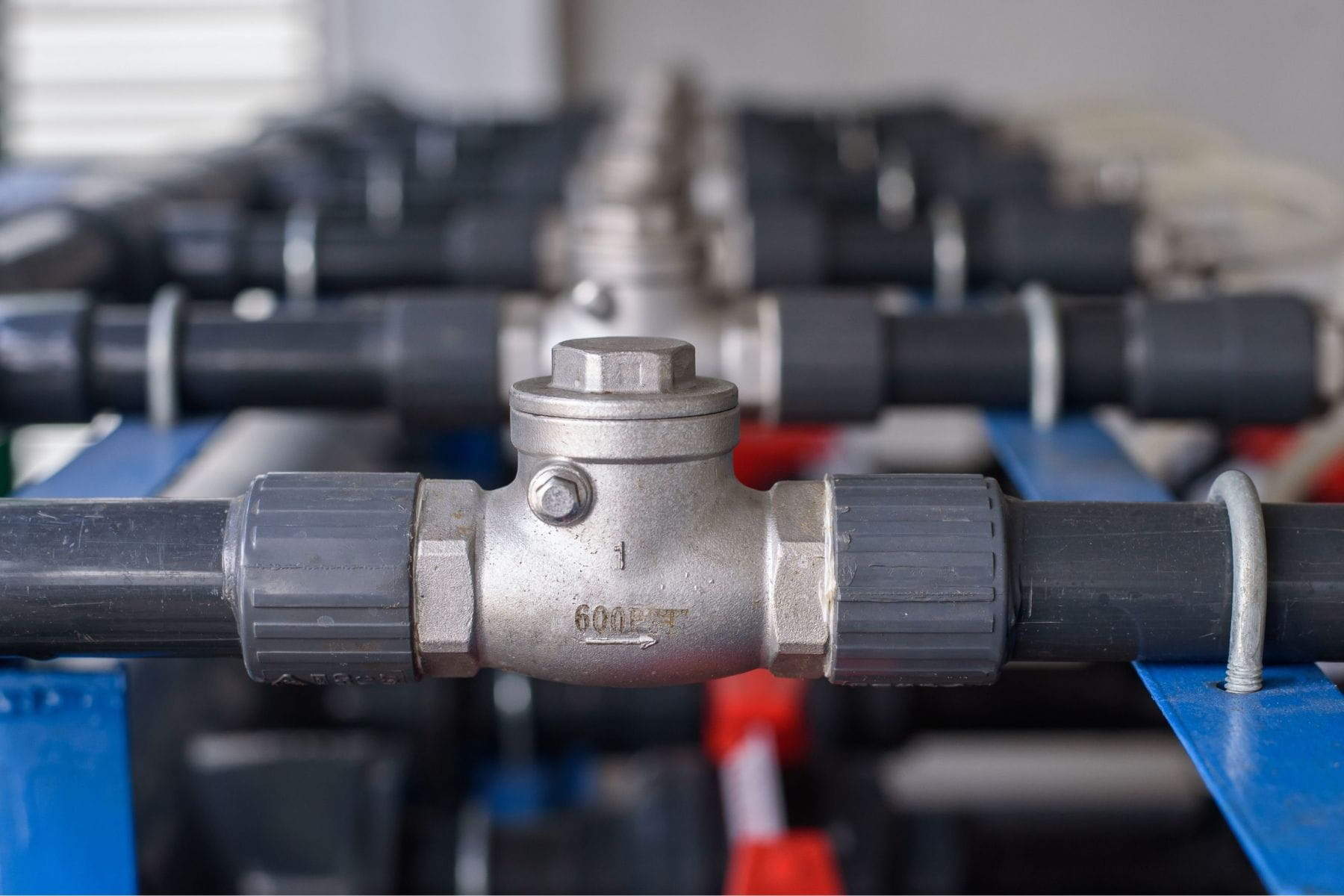

Check valves are widely used for different applications, like downstream of the pump or HVAC system to protect the equipment from backflow.

Most QUALITY Check Valves FOR YOU

The check valve is basically a one-way valve and is also called a non-return valve, it is generally used in pipelines to prevent backflow.

The flow can run freely in one way and in another way the check valve will be closed to protect the piping system from the water hammer. But at the same time, it will also cause pressure loss so in piping design the risk of the water hammer and pressure loss shall be evaluated to select the right valve type.

If you need any support about our Check Valves, pls contact us!

Request a quote

The flow can run freely in one way and in another way the check valve will be closed to protect the piping system from the water hammer. But at the same time, it will also cause pressure loss so in piping design the risk of the water hammer and pressure loss shall be evaluated to select the right valve type.

If you need any support about our Check Valves, pls contact us!

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China