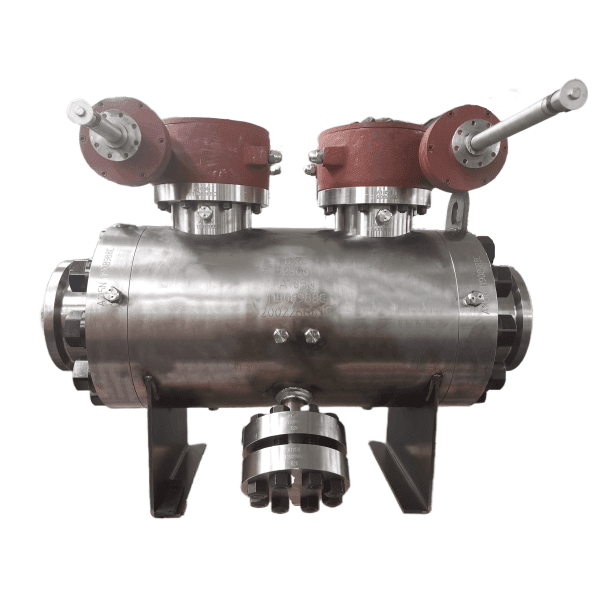

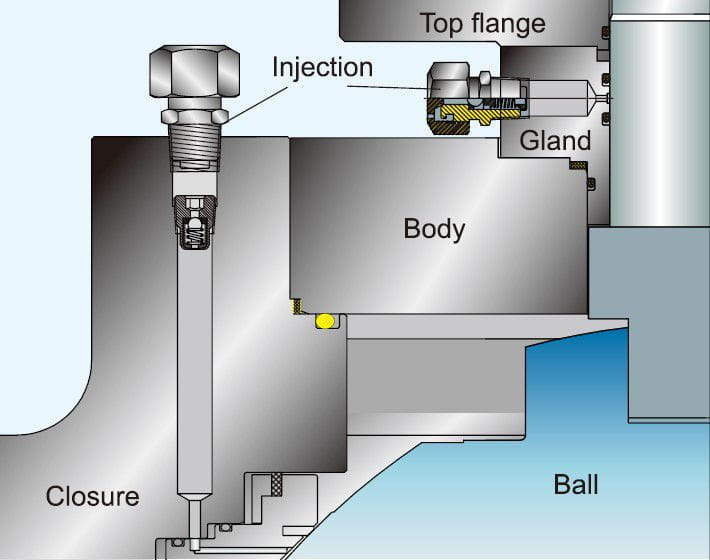

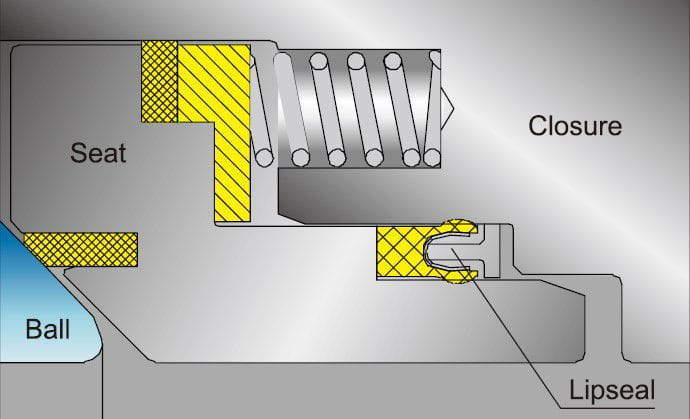

Modular DBB Ball Valve

|

End Connections: Flanged (FF, RF, RTJ), Socket Weld (SW), Threaded (NPT, BSP), Butt Weld (BW), HUB Size Range: 1/4”~60” Pressure Range: 150LB~2500LB, 10000PSI (API 6A Products) Material Range: Cast Steel, Forged Steel, Carbon Steel, Stainless Steel, Alloy Steel, Bronze, Ti |

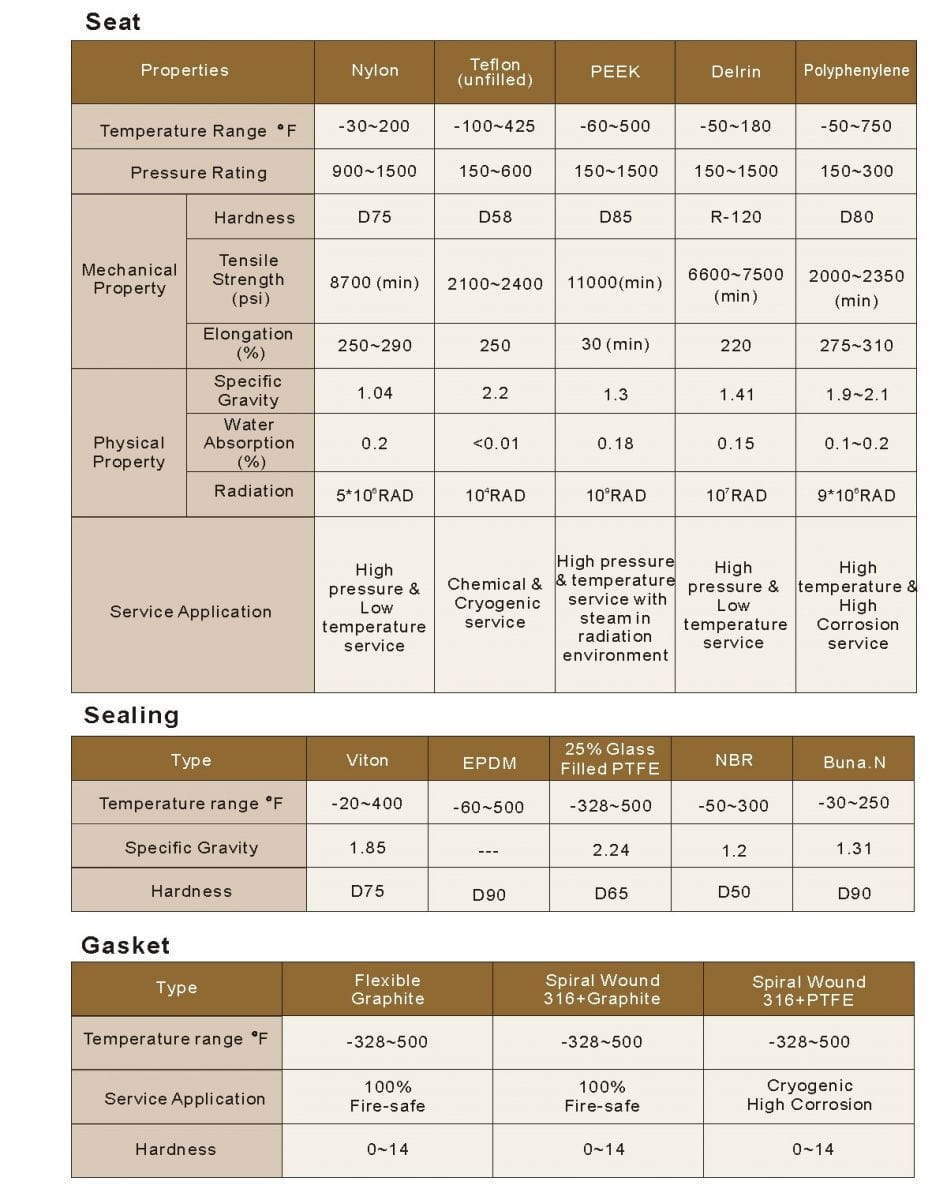

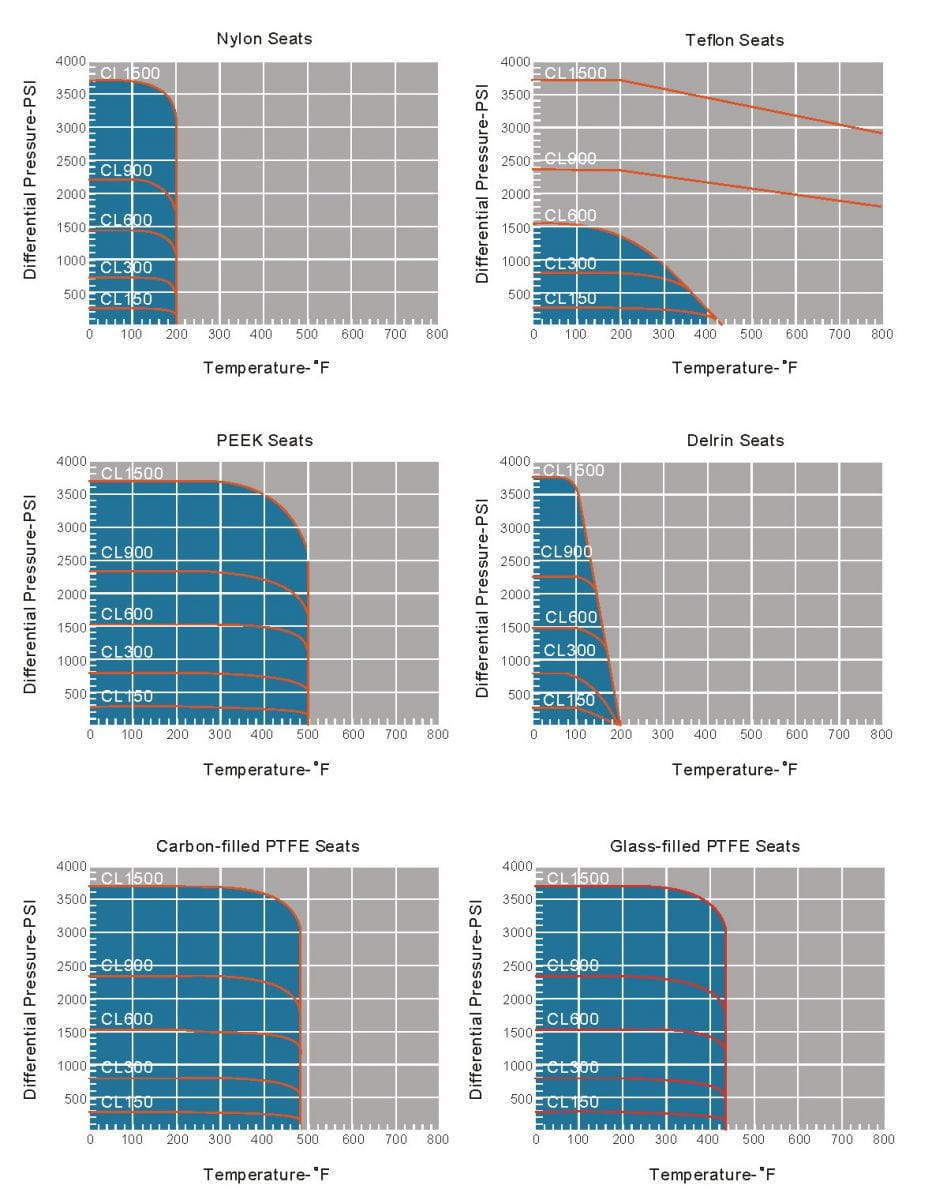

| Mechanical Properties of Soft Seat Materials | Pressure/Temperature Rating of Soft Seat Materials |

|

|