Axial Flow Check Valve

- Home/

- Products/

- Check Valves/

- Axial Flow Check Valve

We have established ourselves as one of the most reputable axial flow check valve manufacturers in China.

Design Standards: API 594, API 6D

Size Range: 2 - 48 Inch

Pressure Range: Class 150-2500 LB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Design Standards: API 594, API 6D

Size Range: 2 - 48 Inch

Pressure Range: Class 150-2500 LB

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Showing 1–12 of 5 results

Top QUALITY Axial Flow Check Valves FOR YOU

An Axial Flow Check valve (also called as a non-slam check valve) is specifically designed for fast-reversing systems where water hammer caused by backflow is a constant concern.

If you need any support with our Ball Valves, pls contact us!

Request a quote

If you need any support with our Ball Valves, pls contact us!

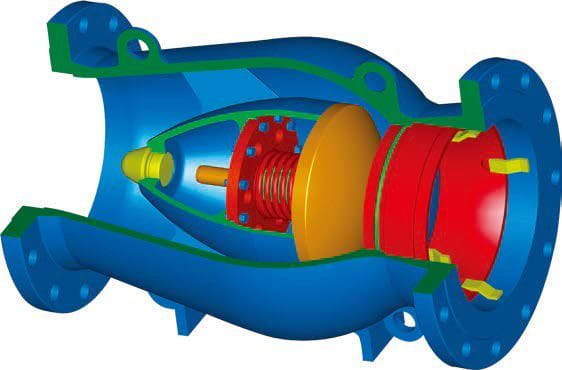

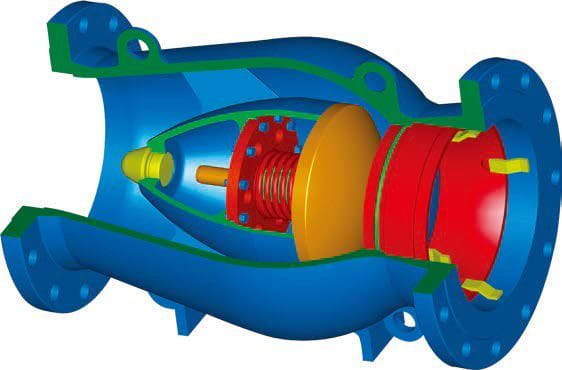

An Axial Flow Check valve is a spring-loaded non-return valve, with one piece body, a spring-loaded low-mass disc, a seat, and a streamlined port, it can provide a fast and dynamic response to flow reduction.

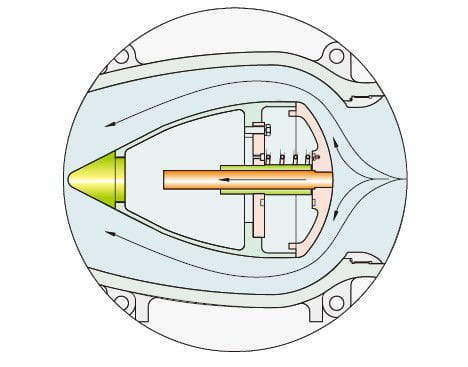

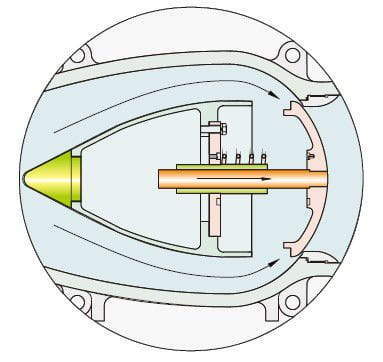

When the valve is open, the force of spring and flow is dynamic and balanced to result in an even flow, and the streamlined flow path can minimize the pressure loss. Due to spring load, low mass disc and shorter travel, the disc can be closed as quickly as possible without slamming (no excess pressure spikes).

The axial flow check valve can be used in a wide range of critical and demanding service applications, such as fast-reversing reciprocating compressor systems or in installations where the check valve must be placed in close proximity to the pump inlet or outlet.

The valve size ranges from 2" to 48" and in pressure rating from ASME class 150 through 2500 and a wide range of body and trim materials for special application requirements.

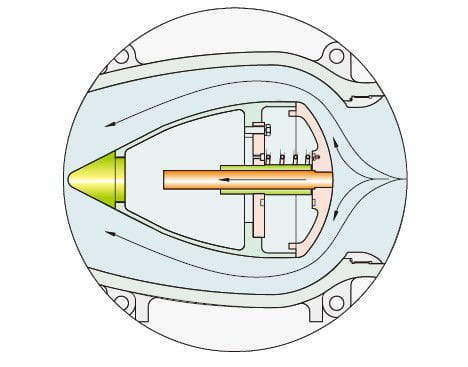

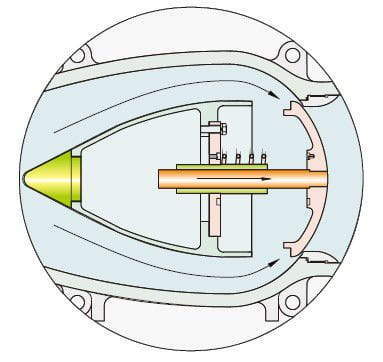

Streamlined Body Design

The whole valve port geometry is a streamlined venturi shape design: both the body and seat design are suitable for medium flowing while the complete surface of the disc is round, and the support frame at the valve outlet is designed into a taper structure. The design features to ensure the flow efficiency of the service medium and minimize pressure loss.

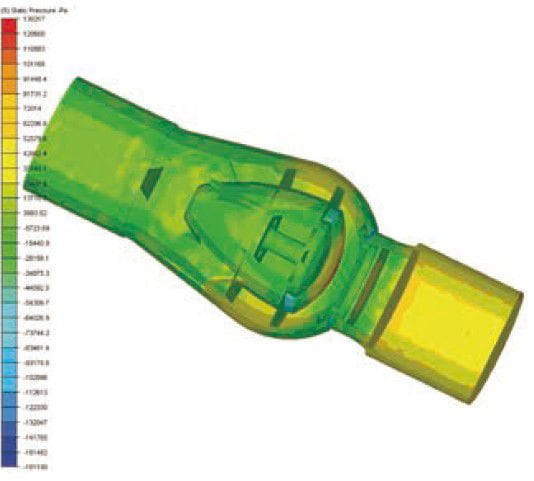

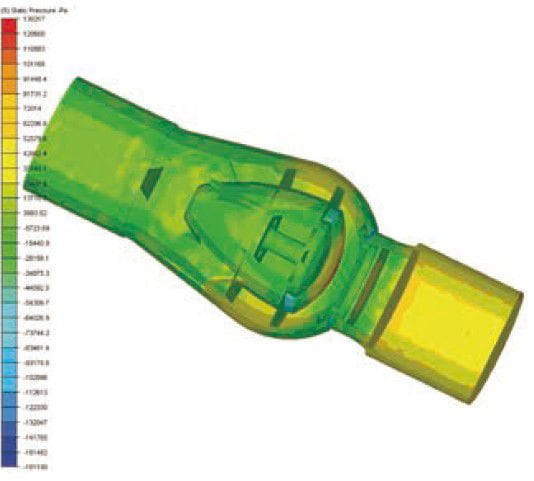

Internal Component's Pressure Distribution

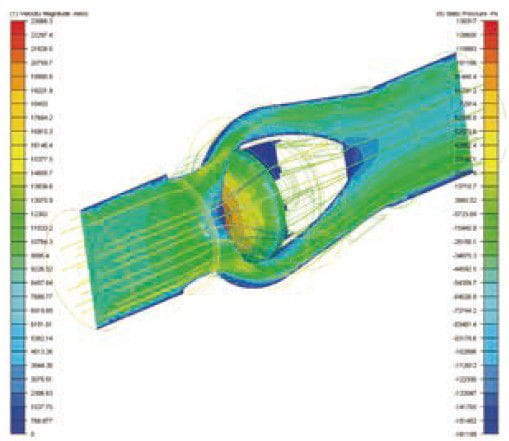

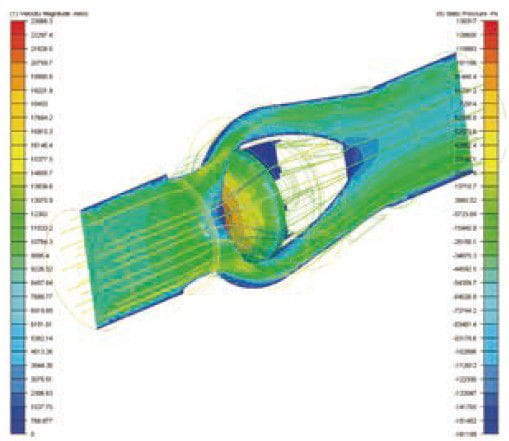

Flow trace and velocity distribution at the cutting plane

Fast Response to Flow Velocity Change

As the inlet flow reduces, the disc reacts immediately so as to limit medium backflow and valve slamming. Because of the features of the spring load, low mass disc and shorter travel, the disc can be closed as quickly as possible. At the moment of zero flow, the disc is fully closed.

Sealing under low pressure

Under low-pressure conditions, the internal spring preload on the disc drives the disc tightly against the seat to seal. Axial flow check valves can overcome the generic problem that the conventional swing check valve has with bad sealing performance under low-pressure conditions.

Long Working Life

In the axial flow check valves, the disc travel is very short, offering high operating reliability and long working life.

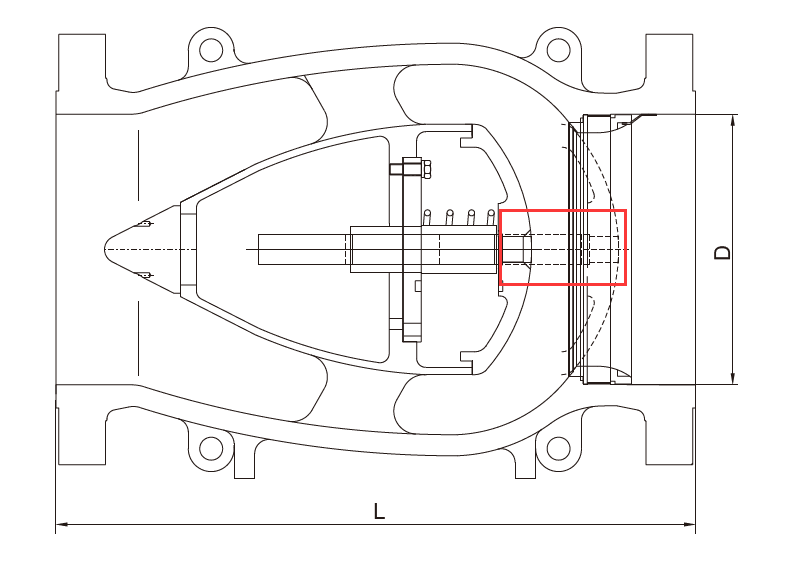

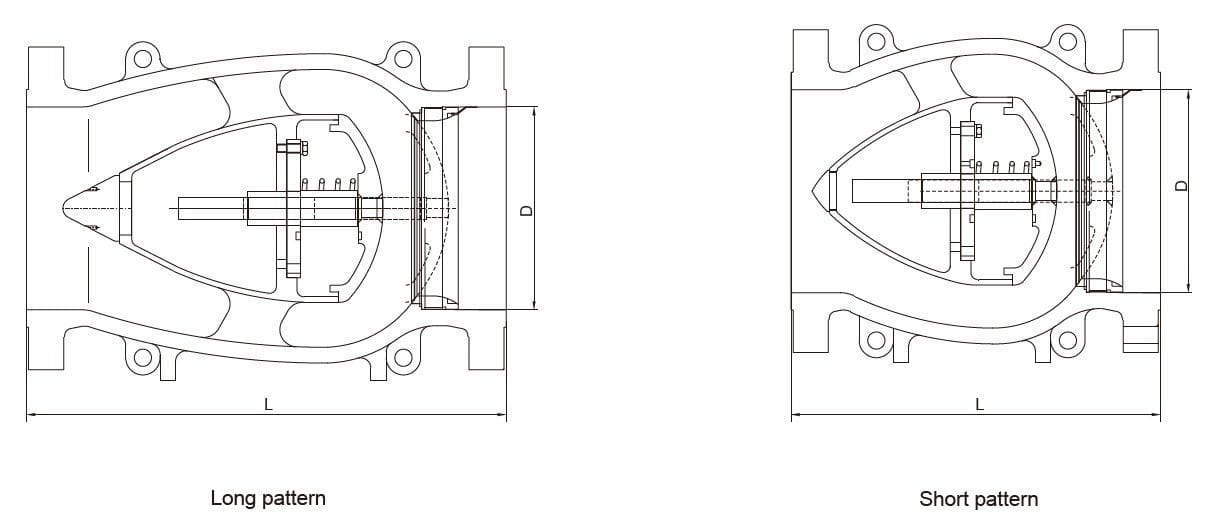

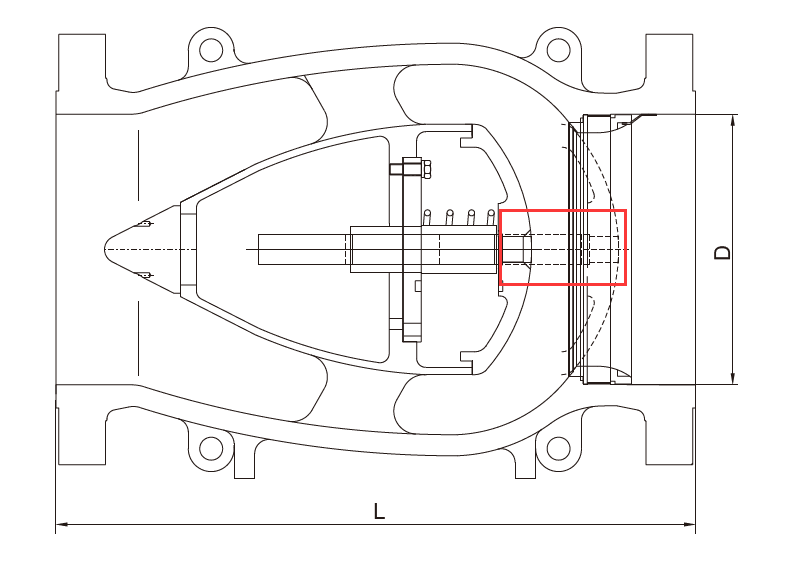

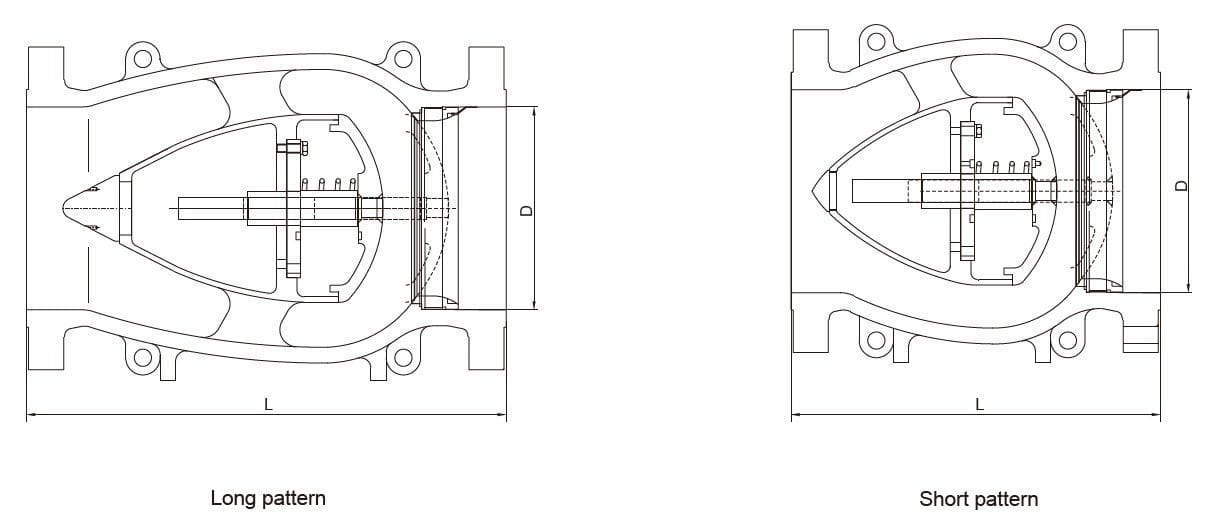

Long Pattern and Short Pattern Available

When the valve is open, the force of spring and flow is dynamic and balanced to result in an even flow, and the streamlined flow path can minimize the pressure loss. Due to spring load, low mass disc and shorter travel, the disc can be closed as quickly as possible without slamming (no excess pressure spikes).

The axial flow check valve can be used in a wide range of critical and demanding service applications, such as fast-reversing reciprocating compressor systems or in installations where the check valve must be placed in close proximity to the pump inlet or outlet.

The valve size ranges from 2" to 48" and in pressure rating from ASME class 150 through 2500 and a wide range of body and trim materials for special application requirements.

Streamlined Body Design

The whole valve port geometry is a streamlined venturi shape design: both the body and seat design are suitable for medium flowing while the complete surface of the disc is round, and the support frame at the valve outlet is designed into a taper structure. The design features to ensure the flow efficiency of the service medium and minimize pressure loss.

Internal Component's Pressure Distribution

Flow trace and velocity distribution at the cutting plane

Fast Response to Flow Velocity Change

As the inlet flow reduces, the disc reacts immediately so as to limit medium backflow and valve slamming. Because of the features of the spring load, low mass disc and shorter travel, the disc can be closed as quickly as possible. At the moment of zero flow, the disc is fully closed.

Sealing under low pressure

Under low-pressure conditions, the internal spring preload on the disc drives the disc tightly against the seat to seal. Axial flow check valves can overcome the generic problem that the conventional swing check valve has with bad sealing performance under low-pressure conditions.

Long Working Life

In the axial flow check valves, the disc travel is very short, offering high operating reliability and long working life.

Long Pattern and Short Pattern Available

About Us

Categories

Useful Links

Our Contacts

Building 2, NO.59, Songshan Road, SND, Suzhou, China