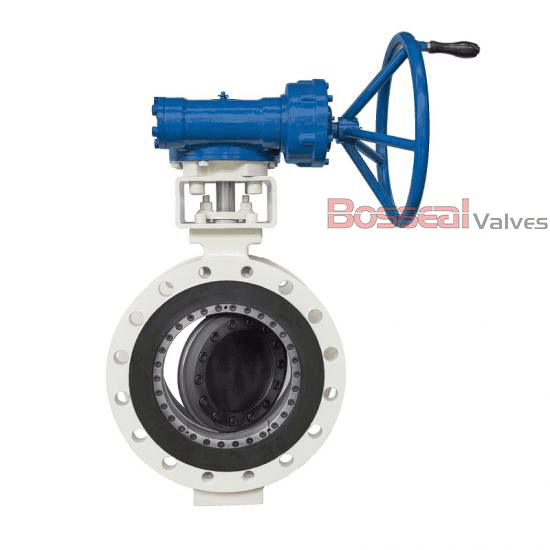

High-Performance

Butterfly Valves, 12 IN/DN300, 300 LB, Double Offset, Double Flanged End.

1862145 High-Performance Butterfly Valve

Design Standard: API 609 Category B, EN 593

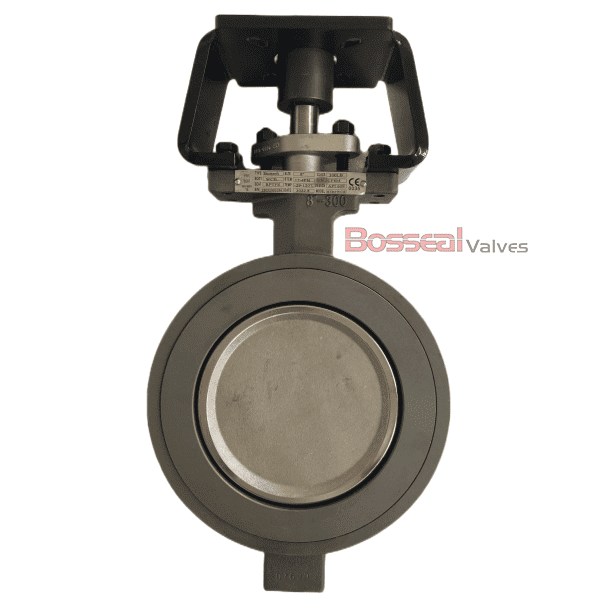

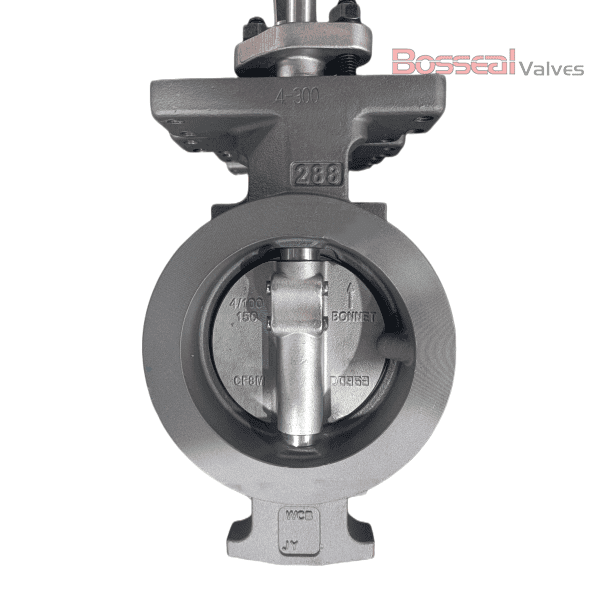

Structure: Double Offset, Double Eccentric

Body Material: ASTM B148 C95800, ASTM A890 4A, ASTM A216 WCB, ASTM A890 5A, ASTM A351 CF8, ASTM A351 CF8M, Titanium

Nominal Size: 12 Inch, DN300

Nominal Class: Class 300 LB, PN50

Seat Type: Soft Seat

Operation: Gear

Trim Material: ASTM B148 C95800, ASTM A351 CF8, ASTM A351 CF8M, ASTM A890 4A, ASTM A890 5A, Titanium

Seat: RPTFE, PPL

End Connection: Double Flanged

Face to Face: API 609, EN 593

Test and Inspection: API 598, API 609

1. Long lifespan for high-frequency operation (up to a million cycles)

2. Reduced torque for smoother operation

3. Replaceable seat for easy maintenance

4. Reliable tight sealing performance

5. Superior control characteristics

6. Bi-directional sealing under full pressure

7. Fire-safe seat option available

Body Material: Carbon Steel, Stainless Steel, Duplex Steel, Aluminum Bronze, Titanium

Normal Diameter: 1/2 - 48 Inch (DN15 - DN1200)

Pressure Range: Class 150 - 300 LB

End Connection: Wafer, Lug, Flanged

Working Temperature: -26°C - +120°C (180°C for PPL seat)

Operation: Manual (lever, gear), Pneumatic Actuator, Motor Actuator

This valve offers significant cost and space savings compared to other valve types, with a broader size range, faster operation, and reduced restriction and wear between the disc and seat sealing surfaces. These features contribute to a longer service life and lower total cost of ownership. With its two-offset design, the valve provides extended durability and lower torque, making it ideal for frequent operation. Bosseal's high-performance butterfly valve has successfully passed a million-cycle test.