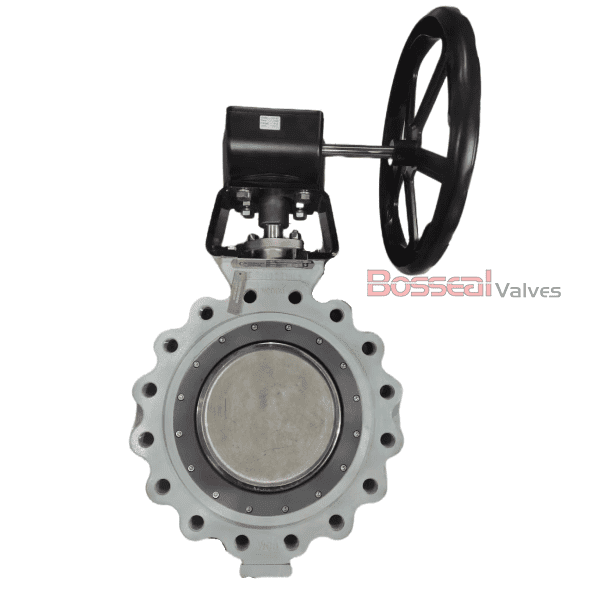

High-Performance

Butterfly Valve, 4 Inch/DN100, 300 LB, Soft Seat, Lug End, Lever Operation.

1862078 High-Performance Butterfly Valve

Design Standard: EN 593, API 609 Category B

Structure: Double Offset, Double Eccentric

Nominal Size: 4 Inch, DN100

Nominal Class: Class 300 LB, PN50

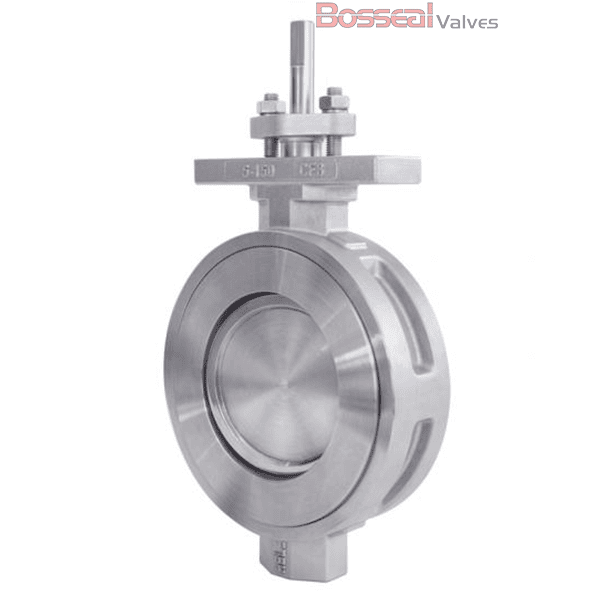

Seat Type: Soft Seat

Operation: Lever

Body Material: ASTM A890 4A, ASTM B148 C95800, ASTM A890 5A, ASTM A351 CF8M, ASTM A216 WCB, ASTM A351 CF8, Titanium.

Seat: RPTFE, PPL

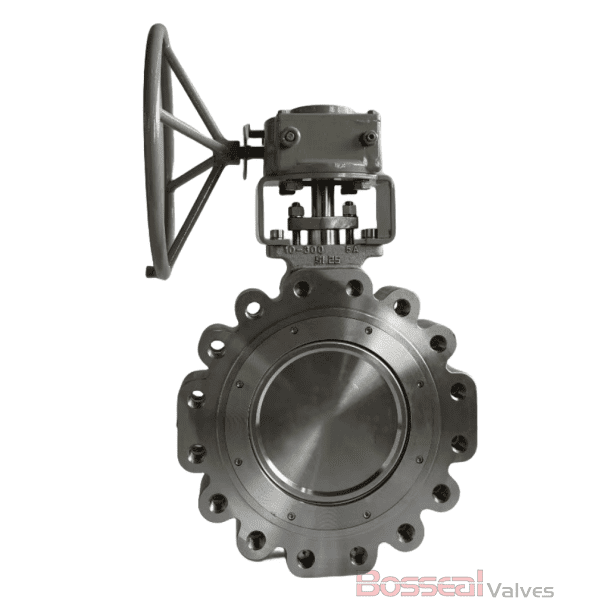

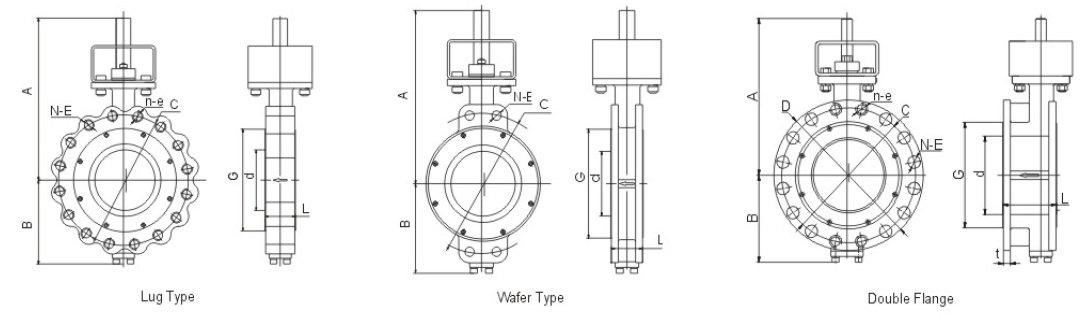

End Connection: Lug

Face to Face: API 609, EN 593

Test and Inspection: API 598, API 609

Trim Material: ASTM A351 CF8, ASTM A351 CF8M, ASTM A890 4A, ASTM A890 5A, ASTM B148 C95800, Titanium

1. Long lifespan for high-frequency operation (up to a million cycles).

2. Reduced torque for smoother operation.

3. Replaceable seat for easy maintenance.

4. Reliable tight sealing performance.

5. Superior control characteristics.

6. Bi-directional sealing under full pressure.

7. Fire-safe seat option available.

Body Material: Carbon Steel, Stainless Steel, Duplex Steel, Aluminum Bronze, Titanium

Normal Diameter: 1/2 Inch - 48 Inch (DN15 - DN1200)

Pressure Range: Class 150 LB - 300 LB

Operation: Manual (lever, gear), Pneumatic Actuator, Motor Actuator

Working Temperature: -26°C - +120°C (180°C for PPL seat)

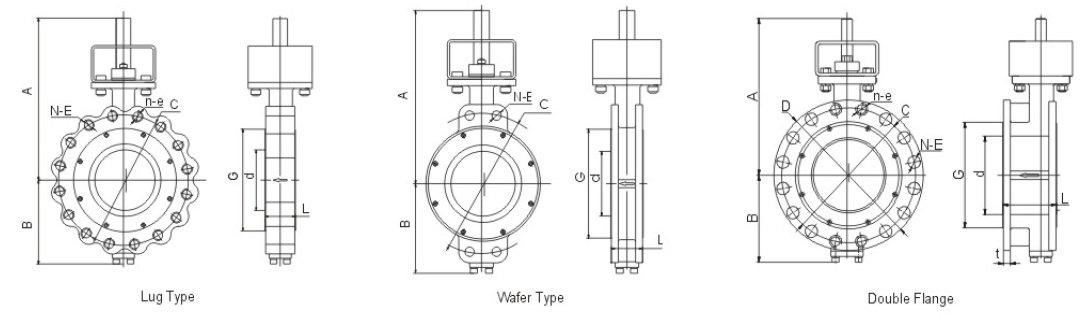

End Connection: Wafer, Lug, Flanged

When the valves need to be installed at end of the pipe and one side no connection with ant pipe/flange, the valve need special design like threaded holes and bi-direction sealing.

Easy Maintenance

The seat is replaceable and can be easily disassembled by loosing the seat retainer with special tools.

Fire safe with dual seal including primary soft PTFE seat and secondary metal seat, in event of fire the soft seat is destroyed the metal seat will provide effective shut-off.